Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT ADJUSTMENT, INSPECTION AND REPLACEMENT)

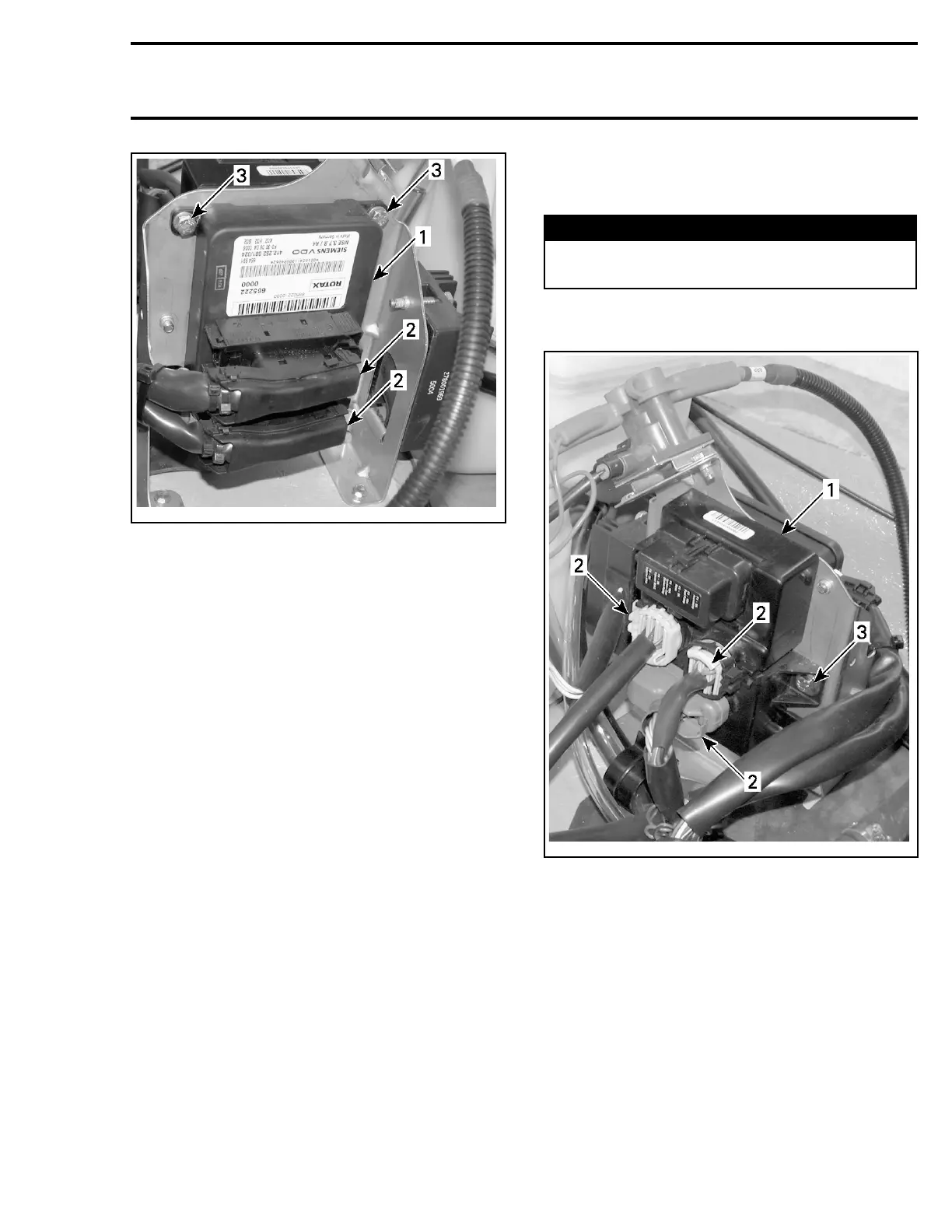

smr2005-056-005

TYPICAL

1. ECM

2. ECM connectors

3. Retaining screws

CAUTION: If ever ECM is replaced, replace it by

the same part or by an approved equivalent.

Install the new ECM to its bracket.

Reconnect ECM connectors then battery cables.

If the previous ECM was read with B.U.D.S.

Transfer the data from the previous ECM to the

new one using B.U.D.S.

Continue procedure as per FINALIZING ECM RE-

PLACEMENT below.

If the previous ECM was NOT read

with B.U.D.S.

– Enter the old ECM serial number in the Part

Replacement under History tab. Click on Add

part in History.

– Reprogram safety lanyard(s).

NOTE: The ECM serial number can be found on

the ECM sticker that also shows the P/N.

Continue procedure as per FINALIZING ECM RE-

PLACEMENT below.

Finalizing ECM Replacement

Perform the required resets then, clear all faults

from the newly replaced ECM.

Start the engine and increase engine speed above

5000RPMtobesurenofaultappears.

VCM Replacement

Disconnect battery cables.

WARNING

Battery BLACK negative cable must always be

disconnected first and connected last.

Disconnect connectors from VCM. Remove re-

tainingnutsontop.

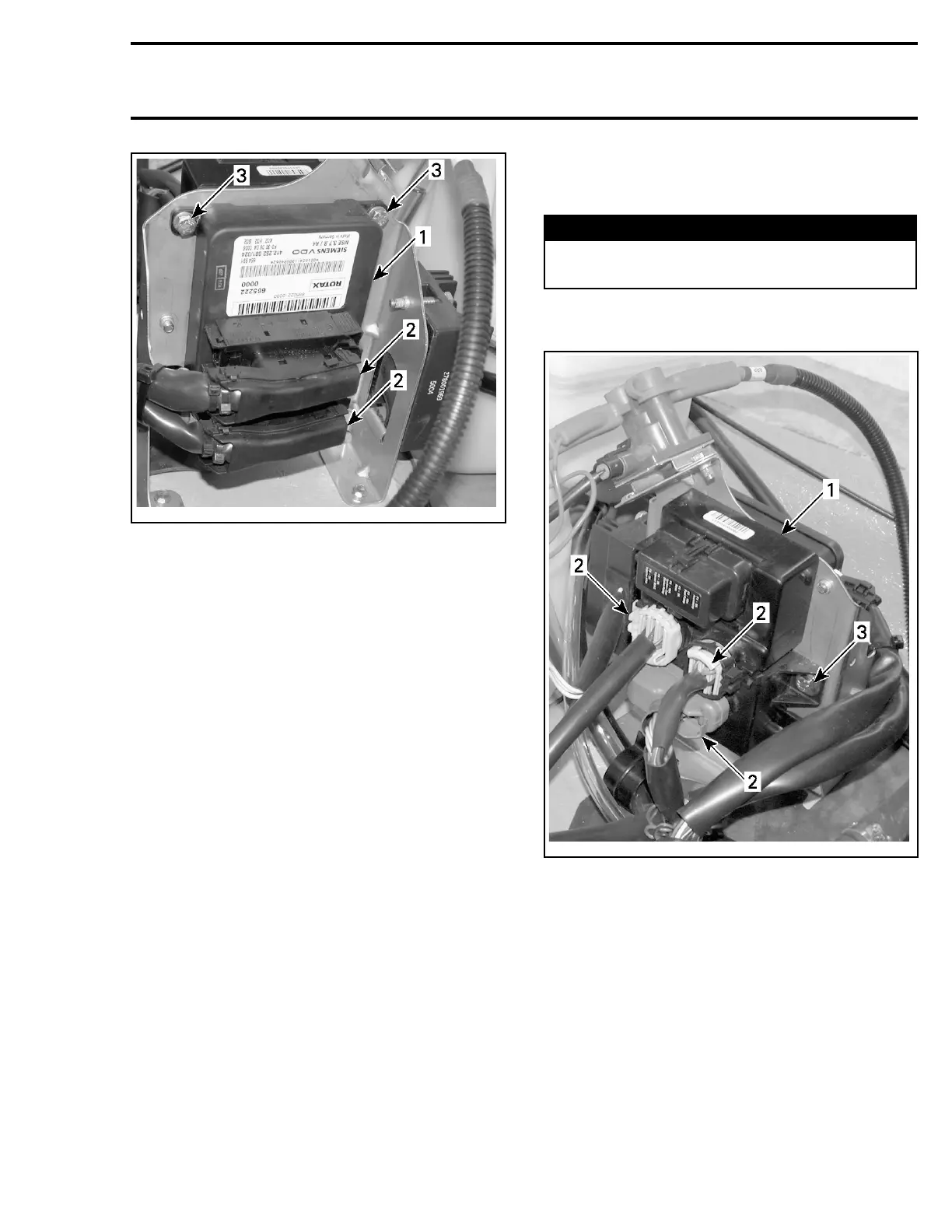

smr2005-056-006

TYPICAL

1. VCM

2. VCM connectors

3. Retaining screws

Pull VCM out.

Install the new VCM on its bracket. Reconnect

connectors to VCM.

THROTTLE POSITION SENSOR

(TPS)

Remove the air intake silencer.

Remove the flame arrester.

smr2005-056 141

Loading...

Loading...