Section 07 ELECTRICAL SYSTEM

Subsection 02 (CHARGING SYSTEM)

TESTING PROCEDURES

NOTE: First, ensure that battery is in good condi-

tion prior to performing the following tests.

BATTERY

Refer to TESTING PROCEDURE of the 787 RFI

ENGINE further in this section for the battery ver-

ifications.

RECTIFIER/REGULATOR

Static Test (Continuity)

Due to internal circuitry, there is no static test avail-

able.

Dynamic Test

Current Test

Proceed with a current test as follows:

– Start engine.

– Lay an inductive ammeter on positive cable of

battery.

– Bringenginetoapproximately6000RPM.

Current reading should be approximately 4 am-

peres for the 717 engine. If not, check magneto

output prior to concluding that rectifier is faulty.

DC Voltage Test

Proceed with a voltage test as follows:

– Start engine.

– Connect a multimeter to battery posts. Set

multimeter to Vdc scale.

– Bringenginetoapproximately5500RPM.

If multimeter reads over 15 volts, regulator is de-

fective. Replace it.

NOTE: If it is continually necessary to add distilled

water to the battery, this indicates an over voltage

situation, requiring replacement of the rectifier/

regulator. If, on the other hand, the battery will not

stay charged, the problem can be any of the charg-

ing circuit components. If these all check good,

you would be accurate in assuming the problem

to be in the rectifier/regulator.

If there is no charging at the battery with the pre-

ceding voltage test, the following test can also be

performed.

Disconnect the connector housing of the rectifier/

regulator.

Using an appropriate terminal remover (Snap-on

TT600-4), remove the RED and BLACK wires from

the tab housing of the rectifier/regulator.

Reconnect the connector housing.

Connect the positive probe of a multimeter to the

REDwireandthenegativeprobetotheBLACK

wire.

Set multimeter to Vdc scale.

Start and rev engine to 3500 RPM. The obtained

value should be between 12 and 25 Vdc.

NOTE: If the rectifier/regulator is within the spec-

ification, either the MPEM or wiring harness

between the rectifier and battery is defective. If

the rectifier/regulator is out of specification and

the battery charging coil (or stator) test good, the

rectifier/regulator is defective.

BATTERY CHARGING COIL

Static Test

Continuity

– Disconnect the magneto wiring harness con-

nector.

– Install the 4-pin magneto harness adapter

(P/N 295 000 131) to the magneto wiring har-

ness. Leave wiring harness side disconnected.

F01B28A

TYPICAL

– Check resistance between the YELLOW and

BLACK/YELLOW wires of the magneto harness

adapter. Refer to the following table.

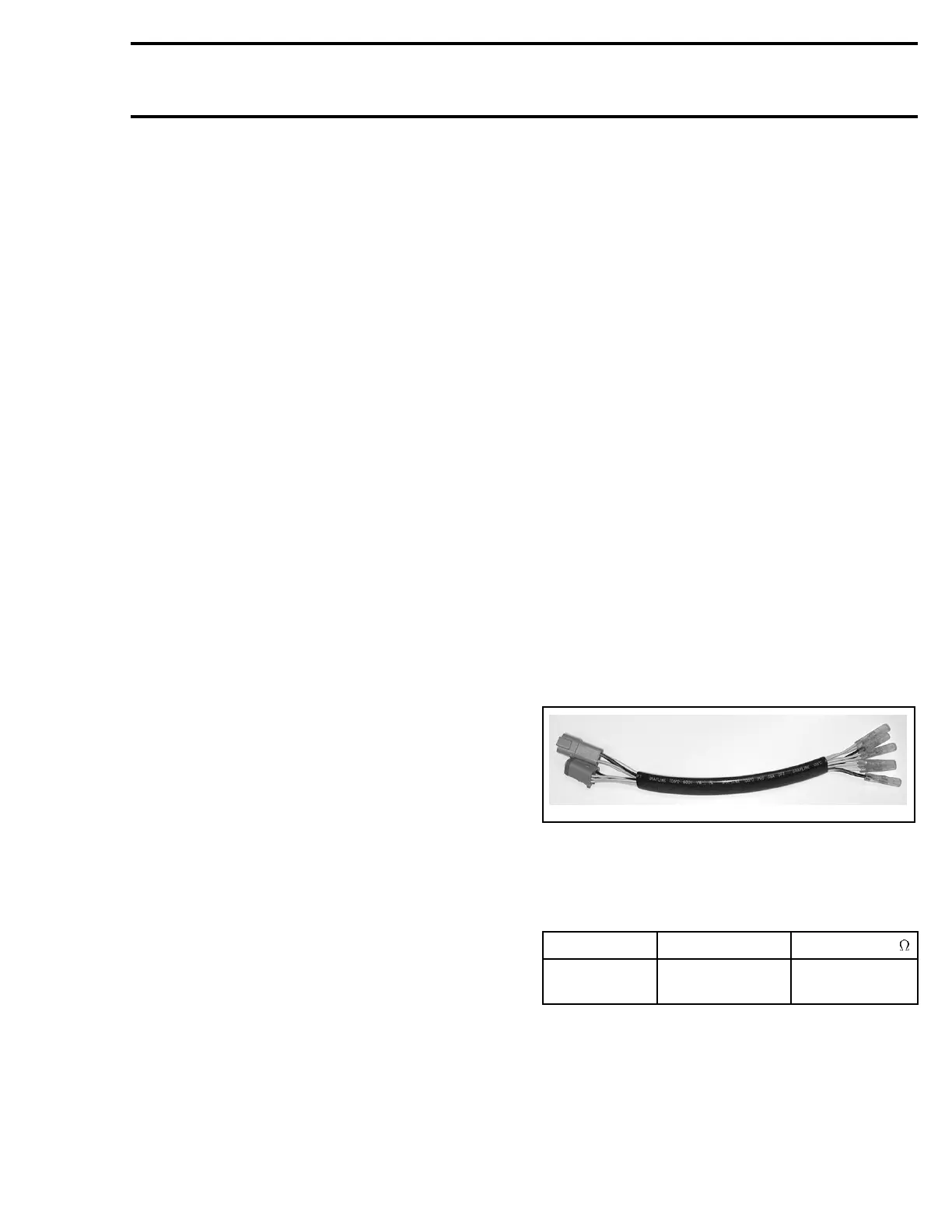

PART NAME WIRE COLOR RESISTANCE

Battery

charging coil

YELLOW with

BLACK/YELLOW

0.05 - 0.6

NOTE: Ashortc

ircuit will read 0 ohm (or close to)

on ohmmeter

.

smr2005-058 167

Loading...

Loading...