Section 04 LUBRICATION SYSTEM

Subsection 02 (OIL INJECTION PUMP)

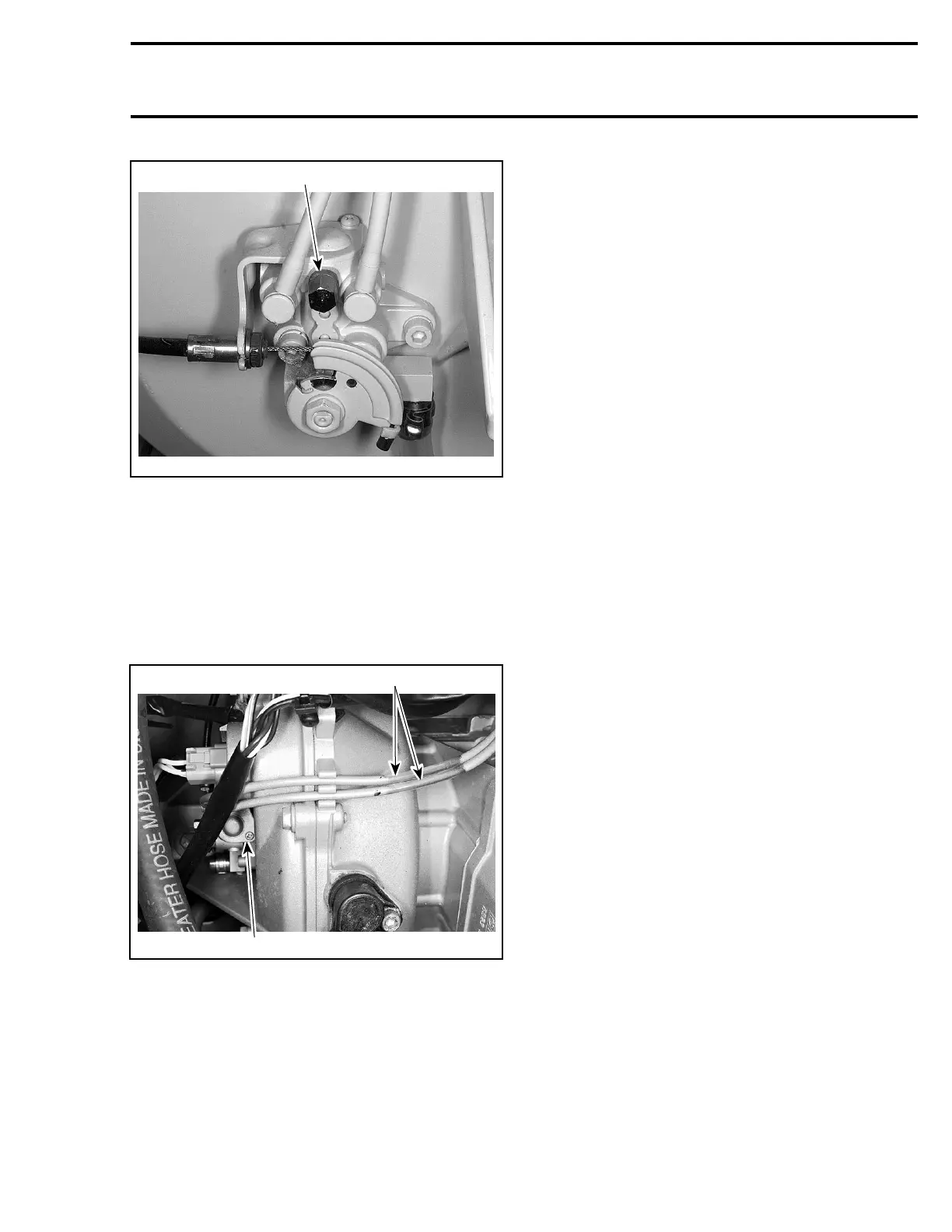

F07G02A

1

787 RFI ENGINES

1. Bleed screw

Keep bleeding until all air has escaped from line.

Make sure no air bubbles remain in oil supply line.

Tighten bleed screw.

Wipe any oil spillage.

Check small oil lines of the pump. They must be

full of oil.

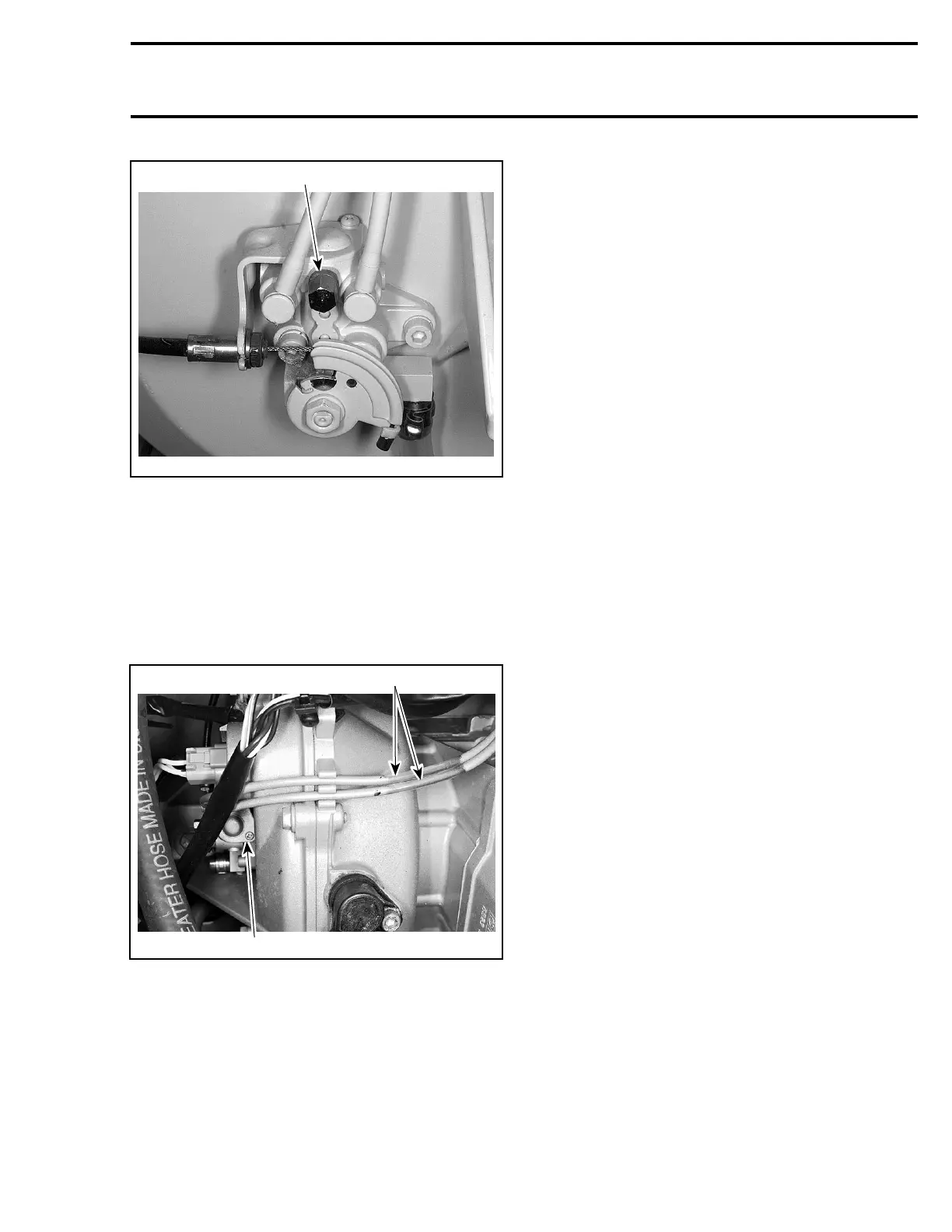

1

2

F07G06A

TYPICAL

1. Lines must be full of oil

2. Oil pump

If not, proceed as follows.

Run engine at idle speed while manually holding

pump lever in fully open position. Do not activate

throttle lever.

CAUTION: If watercraft is out of water, engine

must be cooled using the flush kit.

CHECKING OPERATION

On Watercraft

NOTE: Oil line supply must be full of oil. See

bleeding procedure above.

Start engine and run at idle while holding the pump

lever in fully open position.

Oil must advance into small oil lines.

NOTE: The engine should have a rich mixture,

idling irregularly and emitting smoke at exhaust

outlet.

If not, remove pump assembly and check the

pump gear (717 engines)orshaft(787 RFI en-

gines) for defects, replace as necessary. Test

pump as described below:

NOTE: Through normal use, oil level must not

drop in small tubes. If oil drops, verify check valve

operation. Replace as necessary.

Bench Test

Connect a hose filled with injection oil to main line

fitting. Insert other hose end in an injection oil

container. Using an electric or rechargeable drill in

reverse position, rotate pump shaft. Oil must drip

from fittings in parts of rotary valve cover while

holding lever in a fully open position.

smr2005-051 83

Loading...

Loading...