Section05FUELSYSTEM

Subsection 01 (CARBURETOR)

NOTE: Injectors are also equipped with check

valves.

F04F0JB

1

2

TYPICAL

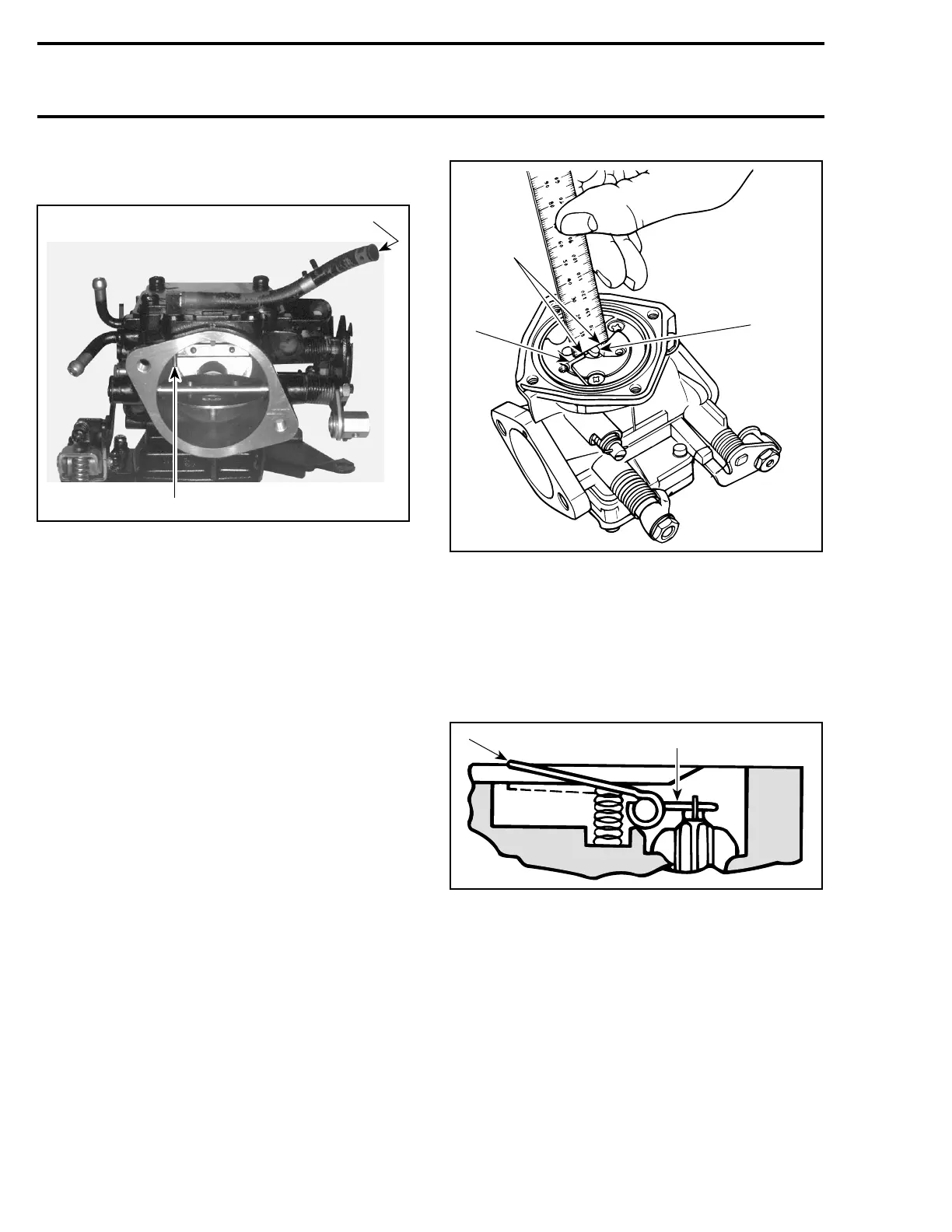

1. Install pump gauge tester to injector hose

2. Injector

Pump tester. Injector check valve should open at

19.4 kPa ± 4.7 (2.8 ± .6 PSI).

NOTE: If the obtained pressure is too low, the

check valve is leaking. If it is too high, less fuel will

be delivered which may lead to engine hesitation

under acceleration.

ASSEMBLY

When assembling pump, ensure to properly posi-

tion components together. Refer to previous illus-

trations if necessary.

Choke Plate and Throttle Plate

When installing choke plate no. 11 or throttle plate

no. 12 onto shaft(s), close plate so that it cen-

ters into carburetor bore. Apply Loctite 243 (blue)

(P/N 293 800 060) on thread screws then firmly

tighten screws.

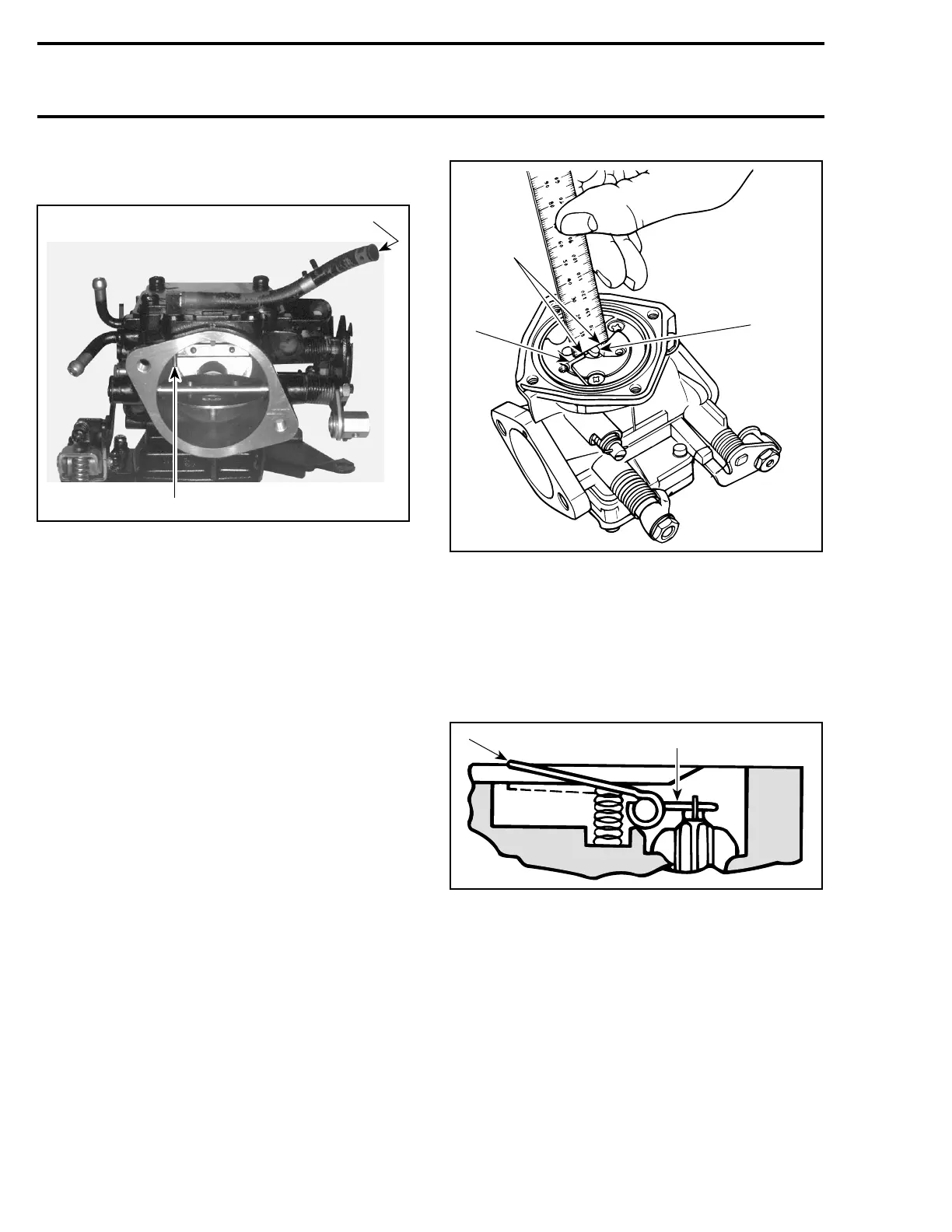

Needle Valve Lever

Rounded end of needle valve lever no. 13 must

be flush with surrounding metering chamber floor

and not with body assembly. Place the end of a

ruler over lever to check adjustment.

1

F01F0ZA

3

2

1. Metering chamber floor

2. Lever end

3. Flush

To adjust, bend lever very slightly to change its

height.

CAUTION: When adjusting lever, do not pry

it so that it applies pressure on needle. This

could damage valve seat/needle.

F01F0HB

1 2

HIGH LEVER

1. Depress here

2. Push tab down

90 smr2005-052

Loading...

Loading...