INTRODUCTION

The owner/operator is not to, and should not al-

low anyone to modify the engine in any manner

that would alter the horsepower or allow emis-

sions levels to exceed their predetermined factory

specifications.

EPA Emission Regulations

All new 1999 and more recent Sea-Doo water-

crafts manufactured by BRP are certified to the

EPA as conforming to the requirements of the

regulations for the control of air pollution from

new watercraft engines. This certification is con-

tingent on certain adjustments being set to factory

standards. For this reason, the factory procedure

for servicing the product must be strictly followed

and, whenever practicable, returned to the origi-

nal intent of the design.

The responsibilities listed above are general and

in no way a complete listing of the rules and regu-

lations pertaining to the EPA requirements on ex-

haust emissions for marine products. For more

detailed information on this subject, you may con-

tact the following locations:

VIA U.S. POSTAL SERVICE:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

401 M St. NW Washington, DC 20460

VIA EXPRESS or COURIER MAIL:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

501 3

rd

St. NW Washington, DC 20001

EPA INTERNET WEB SITE:

http:/www.epa.gov/omswww

SELF-LOCKING FASTENERS

PROCEDURE

The following describes the most common appli-

cation procedures when working with self-locking

fasteners.

Use a metal brush or a screwtap to clean the hole

properly then use a solvent, let act during 30 min-

utes and wipe off. The solventensures the adhe-

sive works properly.

LOCTITE

®

APPLICATION

PROCEDURE

The following describes the most common ap-

plication procedures when working with Loctite

products.

NOTE: Always use proper strength Loctite prod-

uct as recommended in this Shop Manual.

Threadlocker

Uncovered Holes (bolts and nuts)

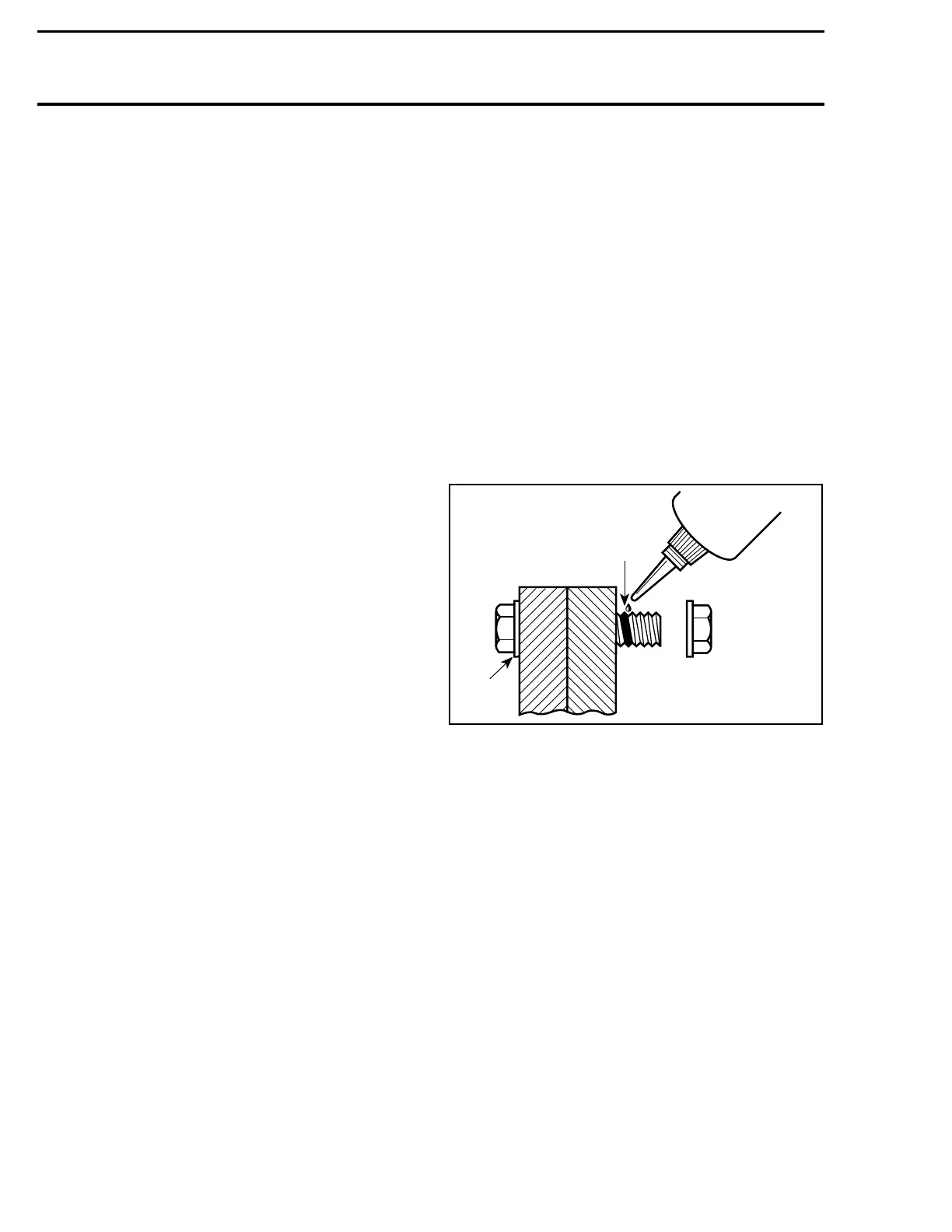

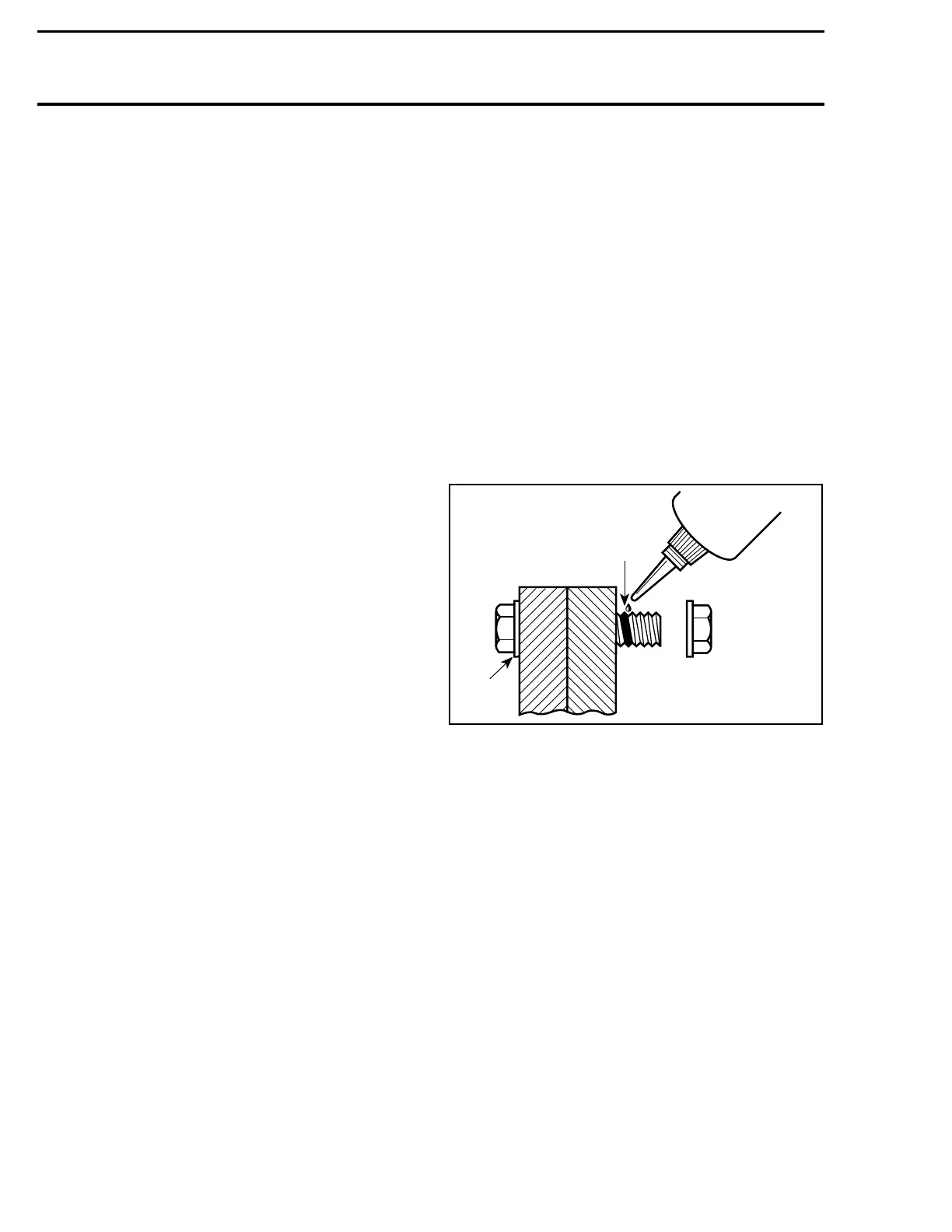

A00A3LA

1

2

1. Apply here

2. Do not apply

– Clean threads (bolt and nut) with solvent.

– Apply Loctite Primer N (P/N 293 800 041) on

threads and allow to dry.

– Choose proper strength Loctite threadlocker.

– Fit bolt in the hole.

– Apply a few drops of threadlocker at proposed

tightened nut engagement area.

– Position nut and tighten as required.

XIV

smr2005-041

Loading...

Loading...