INTRODUCTION

– Spray Loctite Primer N on both mating surfaces

andonbothsidesofgasket. Allowtodry1or

2 minutes.

– Apply GASKET ELIMINATOR 518 (P/N 293 800

038) on both sides of gasket, using a clean ap-

plicator.

– Place gasket on mating surfaces and assemble

immediately.

NOTE: If the cover is bolted to blind holes (above),

apply proper strength Loctite in the hole and on

threads. Tighten.

If holes are sunken, apply proper strength Loctite

on bolt threads.

– Tighten as usual.

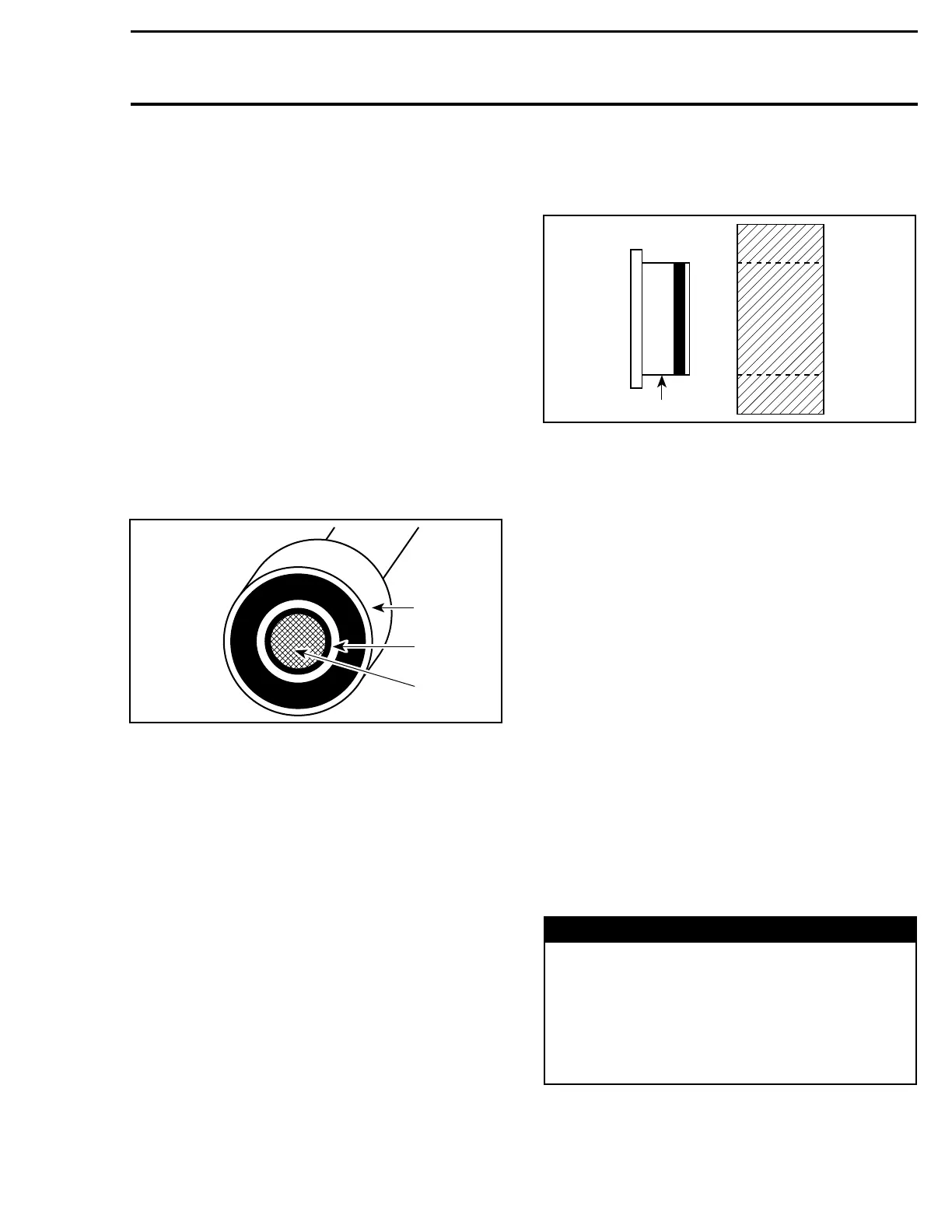

Mounting on Shaft

Mounting with a Press

A00A3UA

1

2

3

1. Bearing

2. Proper strength Loctite

3. Shaft

Standard

1. Clean shaft external part and element internal

part.

2. Apply a strip of proper strength Loctite on

shaft circumference at insert or engagement

point.

NOTE: Retaining compound is always forced out

whenappliedonshaft.

– DO NOT use antiseize Loctite or any similar

product.

– No curing period is required.

Mounting in Tandem

– Apply retaining compound on internal element

bore.

– Continue to assemble as shown above.

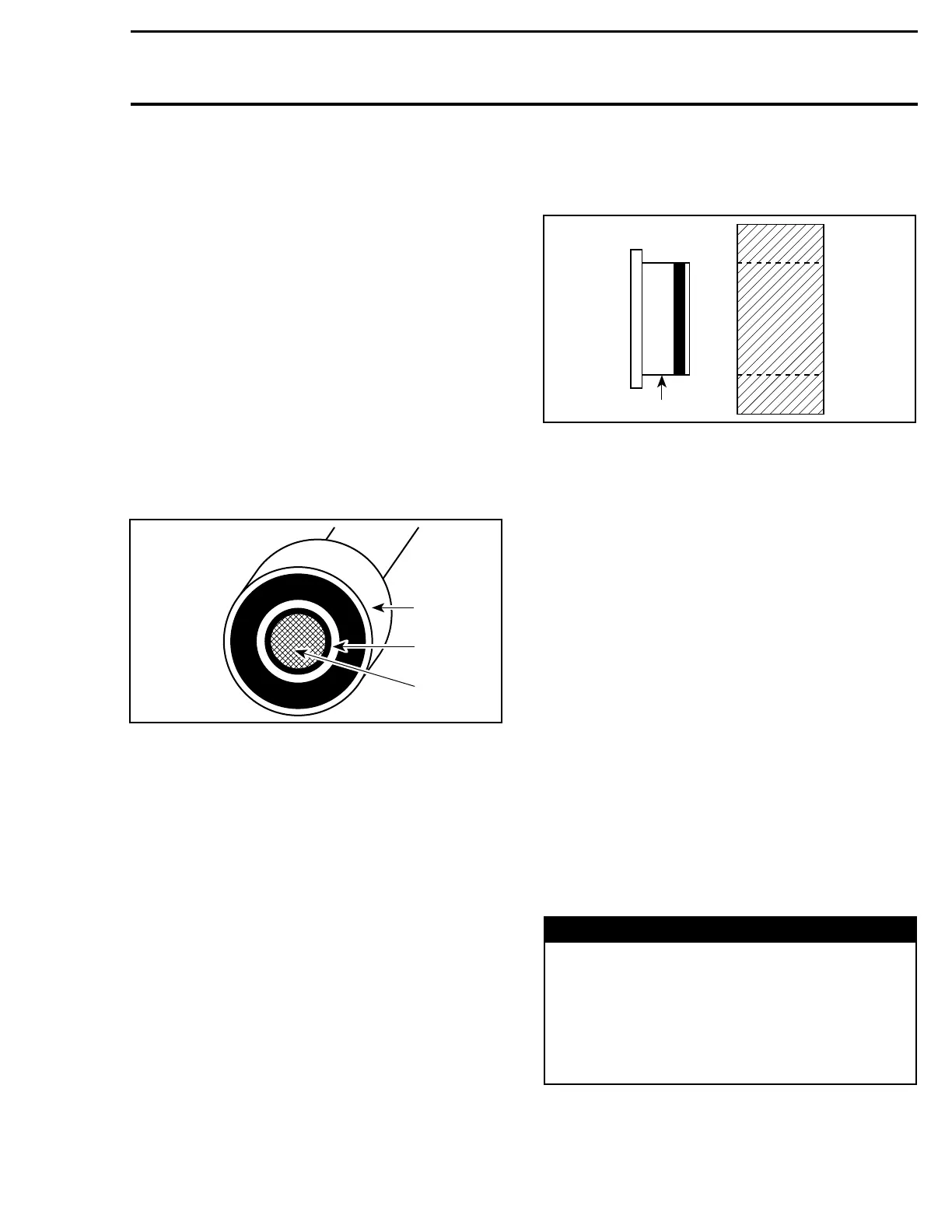

Case-In Components

Metallic Gaskets

A00A3VA

1

1. Proper strength Loctite

– Clean inner housing diameter and outer gasket

diameter.

– Spray housing and gasket with Loctite Primer N

(P/N 293 800 041).

– Apply a strip of proper strength Loctite on lead-

ing edge of outer metallic gasket diameter.

NOTE: Any Loctite product can be used here. A

low strength liquid is recommended as normal

strength and gap are required.

– Install according to standard procedure.

– Wipe off surplus.

– Allow it to cure for 30 minutes.

NOTE: Normally used on worn-out housings to

prevent leaking or sliding.

It is generally not necessary to remove gasket

compound applied on outer gasket diameter.

TIGHTENING TORQUES

Tighten fasteners to torque mentioned in explod-

ed views and/or text, When they are not specified,

refer to following table.

WARNING

Torque wrench tightening specifications

must strictly be adhered to. Locking de-

vices (e.g.: locking tabs, elastic stop nuts,

self-locking fasteners, etc.) must be installed

or replaced with new ones, where specified.

If the efficiency of a locking device is im-

paired, it must be renewed.

smr2005-041 XVII

Loading...

Loading...