INTRODUCTION

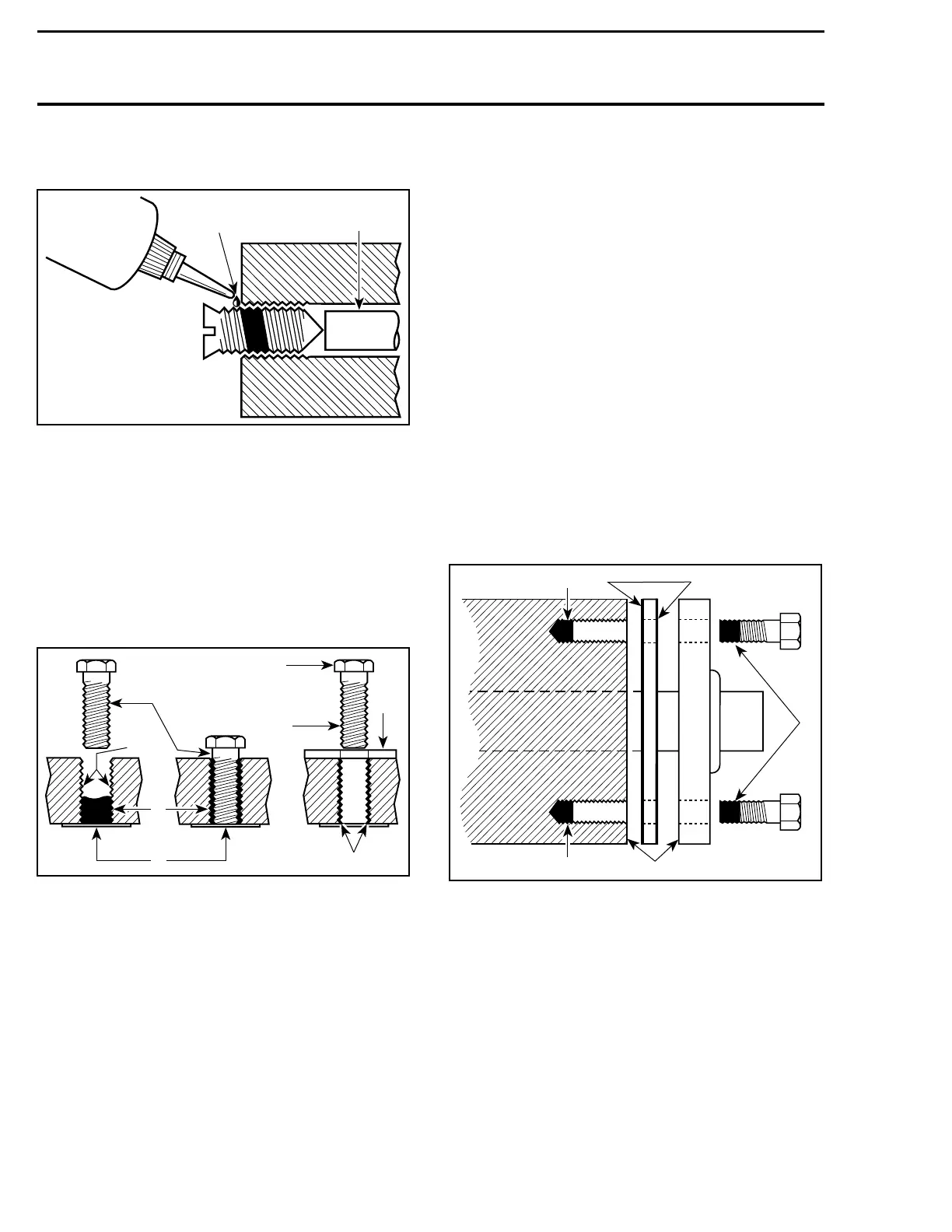

Adjusting Screw

A00A3PA

1

2

1. Apply here

2. Plunger

1. Adjust screw to proper setting.

2. Apply drops of proper strength Loctite thread-

locker on screw/body contact surfaces.

3. Avoid touching metal with tip of flask.

NOTE: If it is difficult to readjust, heat screw with

a soldering iron (232°C(450°F)).

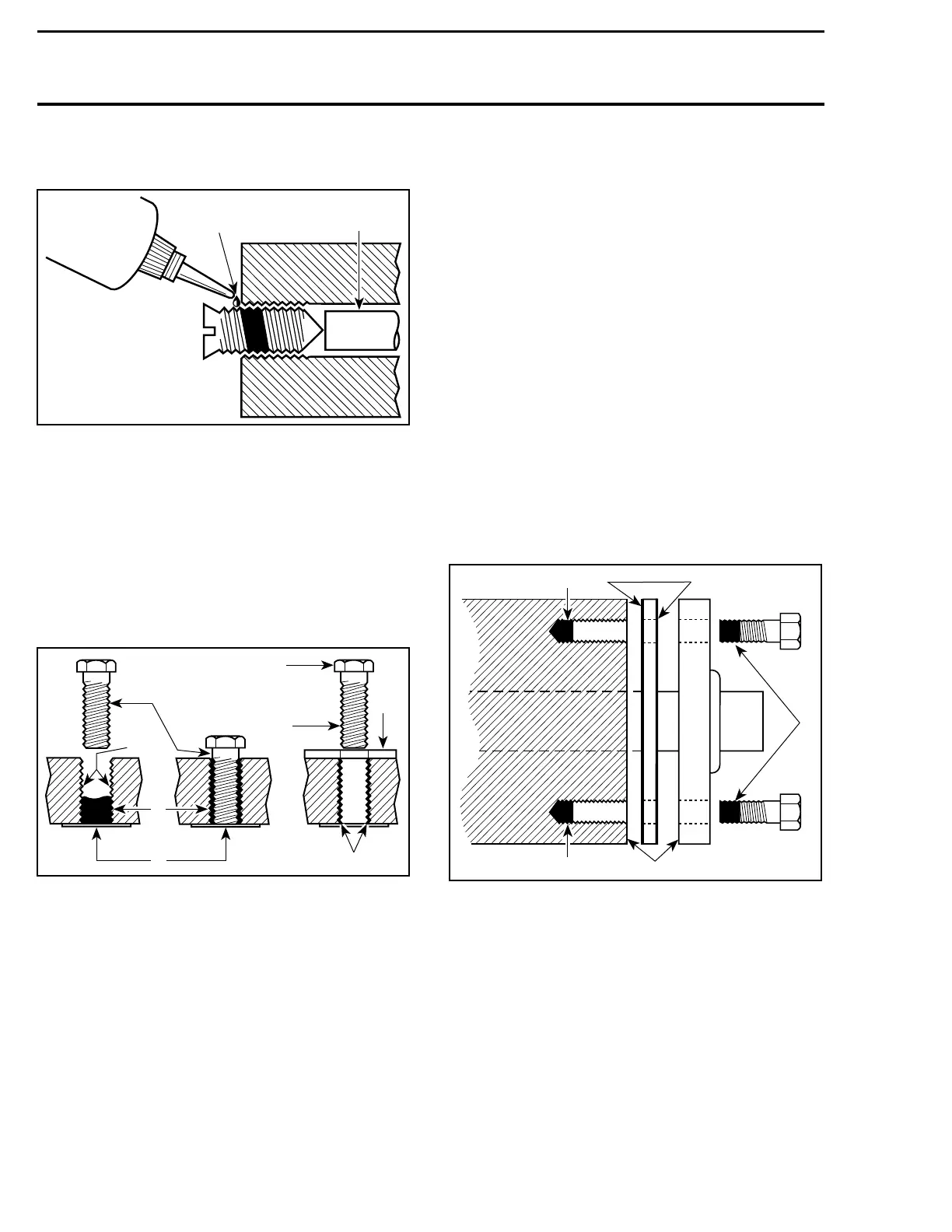

Stripped Thread Repair

A00A3QA

5

8

6

7

1

2

3

4

1. Release agent

2. Stripped threads

3. Form-A-Thread

4. Tape

5. Cleaned bolt

6. Plate

7. New threads

8. Threadlocker

Standard Thread Repair

– Follow instructions on Loctite FORM-A-

THREAD 81668 package.

– if a plate is used to align bolt:

a. Apply release agent on mating surfaces.

b. Put waxed paper or similar film on the sur-

faces.

– Twist bolt when inserting it to improve thread

conformation.

NOTE: NOT intended for engine stud repairs.

Repair of Small Holes/Fine Threads

Option 1: Enlarge damaged hole, then follow

Standard Thread Repair procedure.

Option 2: Apply FORM-A-THREAD on the screw

and insert in damaged hole.

Permanent Stud Installation (light duty)

– Use a stud or thread on desired length.

– DO NOT apply release agent on stud.

– Do a Standard Thread Repair.

– Allow to cure for 30 minutes.

– Assemble.

Gasket Compound

A00A3SA

2

1

1

3

1

1. Proper strength Loctite

2. Loctite Primer N (P/N 293 800 041) and Gasket Eliminator

518 (P/N 293 800 038) on both sides of gasket

3. Loctite Primer N only

– Remove old gasket and other contaminants

with Loctite Chisel remover (P/N 413 708 500).

Use a mechanical mean if necessary.

NOTE: Avoid grinding.

– Clean both mating surfaces with solvent.

XVI

smr2005-041

Loading...

Loading...