Section 04 LUBRICATION SYSTEM

Subsection 01 (OIL INJECTION SYSTEM)

GENERAL

Whenever repairing the oil injection system, al-

ways verify for water infiltration in reservoir.

Also pressure test the oil injection system.

GTI Models

Clamp and Hose

Verify oil filler neck hose no. 2 for damage.

Always ensure that clamps no. 1 are well posi-

tioned and tightened. Torque clamps to 4 N•m

(36 lbf•in).

Check Valve

Black side of the one-way check valve no. 3 is the

valve outlet. It allows air to get in reservoir and

prevent oil to flow out.

NOTE: For proper check valve installation, refer to

appropriate exploded view given at the beginning

of the section.

Oil Filter

Oil filter no. 4 should be replaced annually. When

installing, point the arrow toward the engine.

Oil Reservoir Pad

3D Series

When the foam pad under oil reservoir is installed,

apply Loctite 271 (red) (P/N 293 800 005) on screw

threads.

OIL SYSTEM PRESSURIZATION

WARNING

Whenever oil system components are discon-

nected or replaced, a pressure test must be

done before starting engine. Ensure to veri-

fy oil line ends for damage. Always cut dam-

aged end before reinstallation.

Pressure Test

Proceed as follows:

– Fill up oil reservoir.

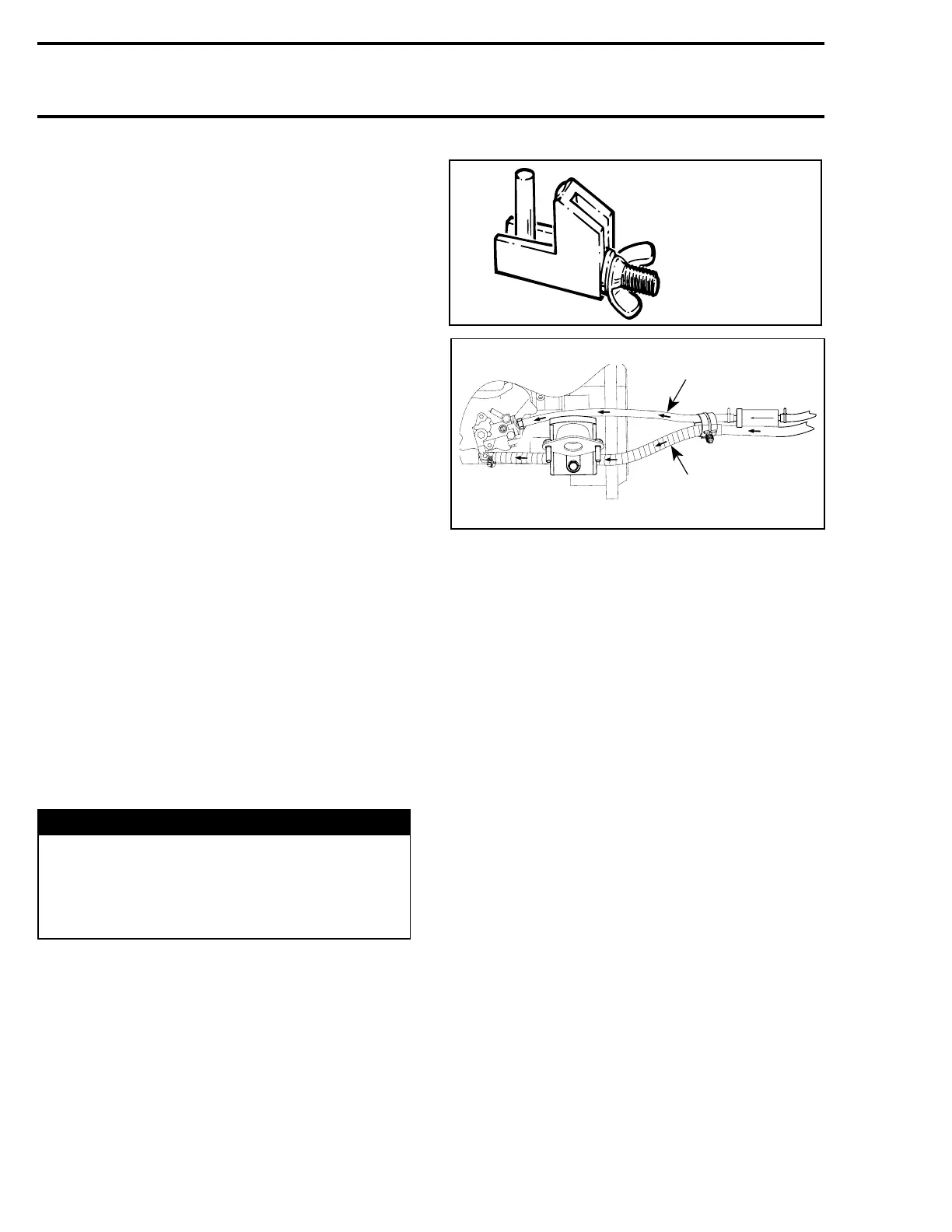

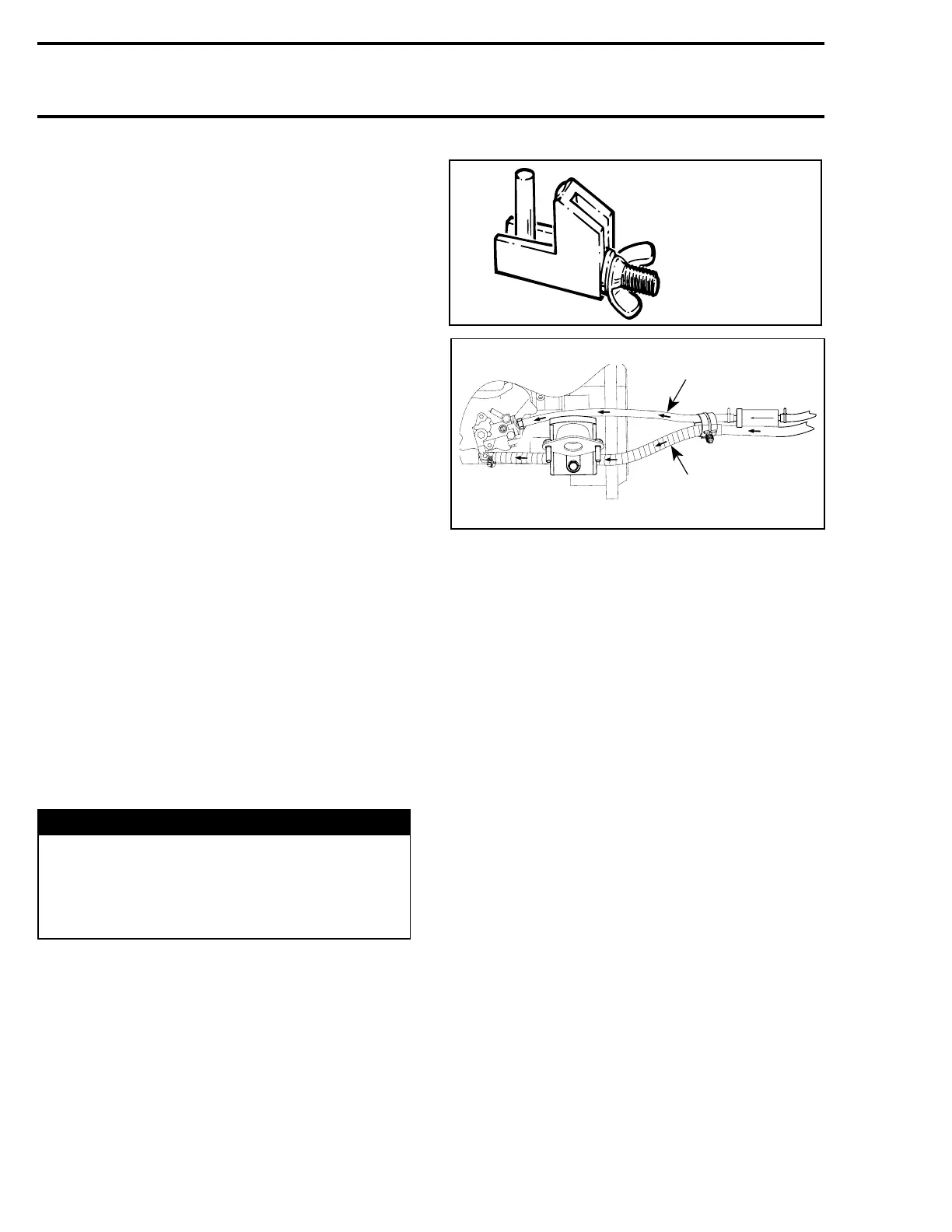

– Install a small hose pincher (P/N 295 000 076)

to rotary valve shaft oil supply hose and to the

oil injection pump supply hose.

295 000 076

1

2

smr2005-050-002_a

717 ENGINES — RH SIDE OF ENGINE

1. Rotary valve shaft oil supply hose

2. Oil injection pump supply hose

74 smr2005-050

Loading...

Loading...