Section 03 ENGINE SYSTEM

Subsection 02 (EXHAUST SYSTEM)

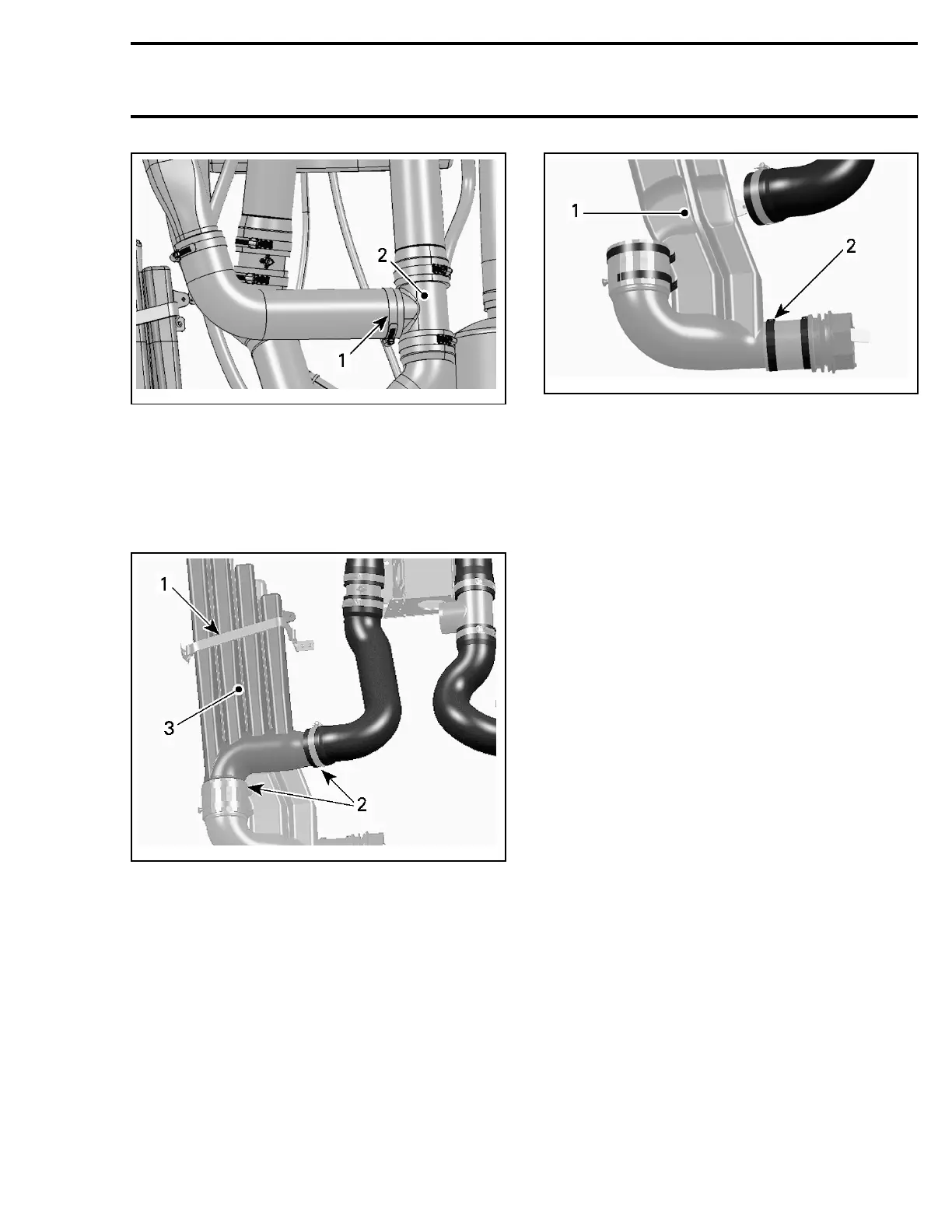

smr2005-048-016_A

1. Straight resonator hose clamp

2. T-fitting

Remove hose with resonator.

Upper Resonator

Remove strap, loosen clamps then pull out res-

onator.

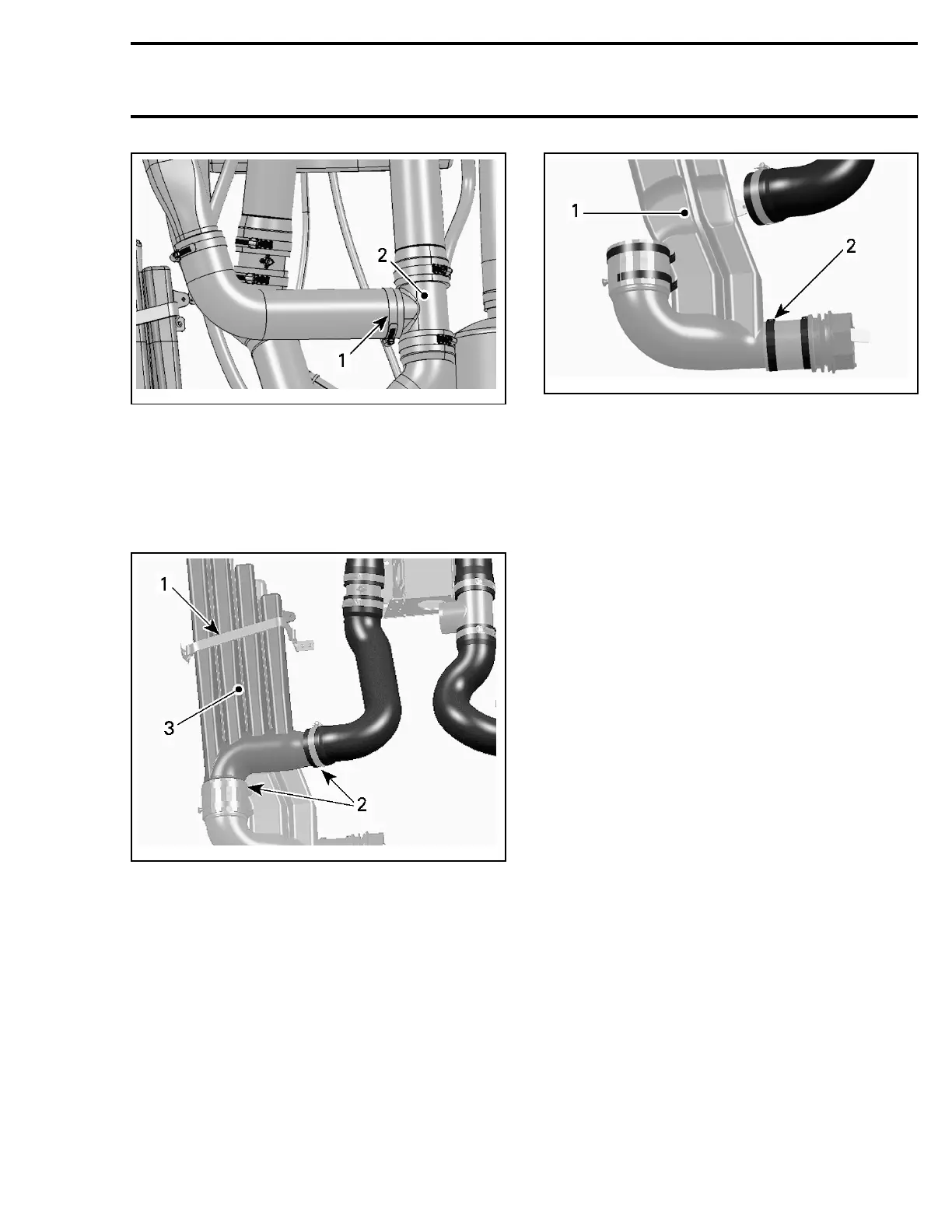

smr2005-048-003_A

1. Resonator strap

2. Clamps

3. Upper resonator

Lower Resonator

Loosen clamp then pull out resonator.

smr2005-048-018_A

1. Lower resonator

2. Clamponhullfitting

REPAIR

Tuned Pipe

This procedure is given to repair tuned pipe cracks

using T.I.G. welding process.

– Sand the cracked area to obtain bare metal.

– Perform a 1.50 mm (1/16 in) depth chamfer over

crack.

– Use pure argon gas with 5.55 mm (3/32 in)

tungsten electrode (puretung “green”,zirtung

“brown”) and AC current.

– Use a 5.55 mm (3/32 in) aluminum welding rod

(no. 4043), to fill crack.

– Sand welding slightly to remove material sur-

plus.

Test

– Usecompressedairat124kPa(18PSI)topres-

surize tuned pipe.

CAUTION: Always ensure water passages are

not blocked partially or completely while weld-

ingtunedpipe.

NOTE: Prior to verify leaks, plug all holes and pres-

surize tuned pipe while immerging it in water.

INSTALLATION

Installation is essentially the reverse of removal

procedures. However, pay particular attention to

the following.

Tuned Pipe

NOTE: Loosen all tuned pipe supports from en-

gine before installing tuned pipe.

smr2005-048 55

Loading...

Loading...