Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT ADJUSTMENT, INSPECTION AND REPLACEMENT)

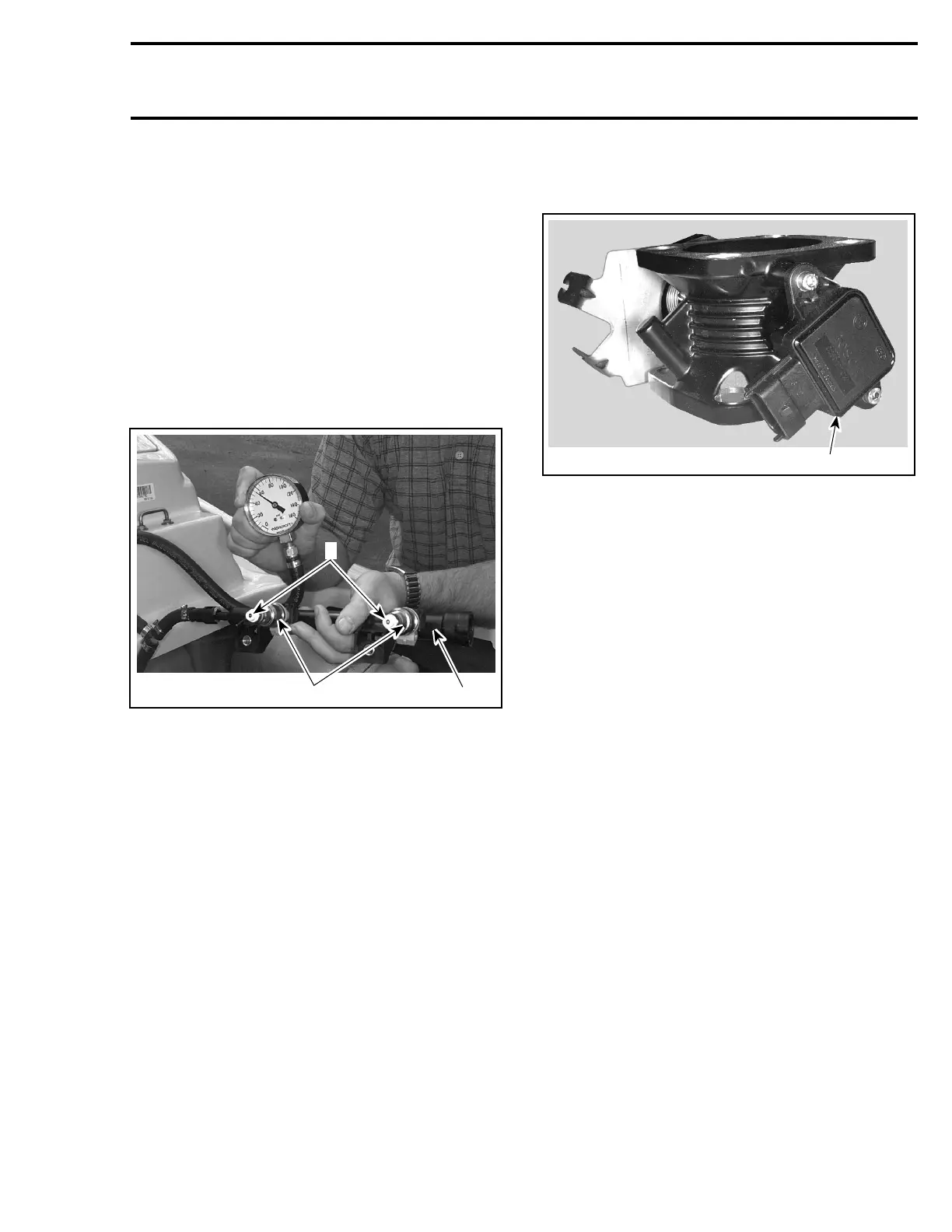

Leakage Test

To perform a leakage test, the injectors and fu-

el rail have to be removed from engine. See RE-

MOVAL in this subsection for the procedure.

NOTE: Do not detach injectors from fuel rail.

Reconnect the wire connector of the injector.

Place each injector in a clean bowl.

Install the safety lanyard cap on the switch to ac-

tivate the fuel pump.

Check for fuel leakage from the injector nozzle.

There should be less than 1 drop of fuel per

minute.

2

1

F07F16A

3

1. Fuel injectors

2. Fuel rail

3. Injector nozzles

If not within specification, replace the fuel injec-

tor(s).

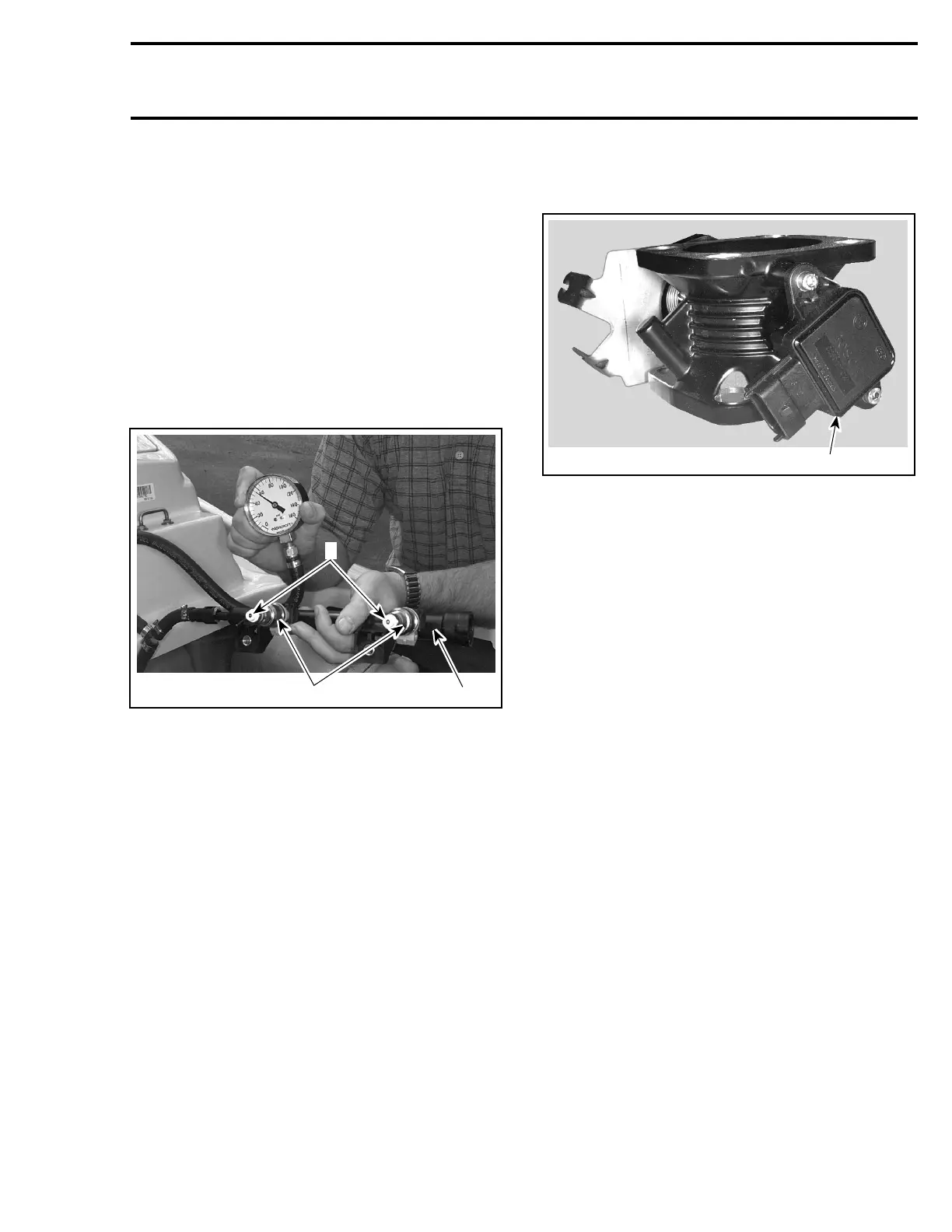

THROTTLE POSITION SENSOR

(TPS)

F07F0EA

1

1. TPS

IMPORTANT: Prior to testing the TPS, ensure that

mechanical components/adjustments of throttle

body are adequate.

The EMS may generate several fault codes per-

taining to the TPS. Refer to DIAGNOSTIC PROCE-

DURES section for more information.

Wear Test

While engine is not running, activate throttle and

pay attention for smooth operation without physi-

cal stops of the cable.

Using the vehicle communication kit (VCK) with

the B.U.D.S. software, use the Throttle Opening

display under Monitoring tab.

Slowly and regularly depress the throttle. Ob-

serve the needle movement. It must change

gradually and regularly as you move the throttle.

If the needle “sticks”, bounces, suddenly drops

or if any discrepancy between the throttle move-

ment and the needle movement is noticed, it

indicates a worn TPS that needs to be replaced.

Resistance Test

Ensure TPS is connected to wiring harness.

Disconnect the A connector from the ECM.

Using a multimeter, check resistance values on

ECM connector as per the following table.

smr2005-056 135

Loading...

Loading...