Section 09 PROPULSION

Subsection 01 (JET PUMP)

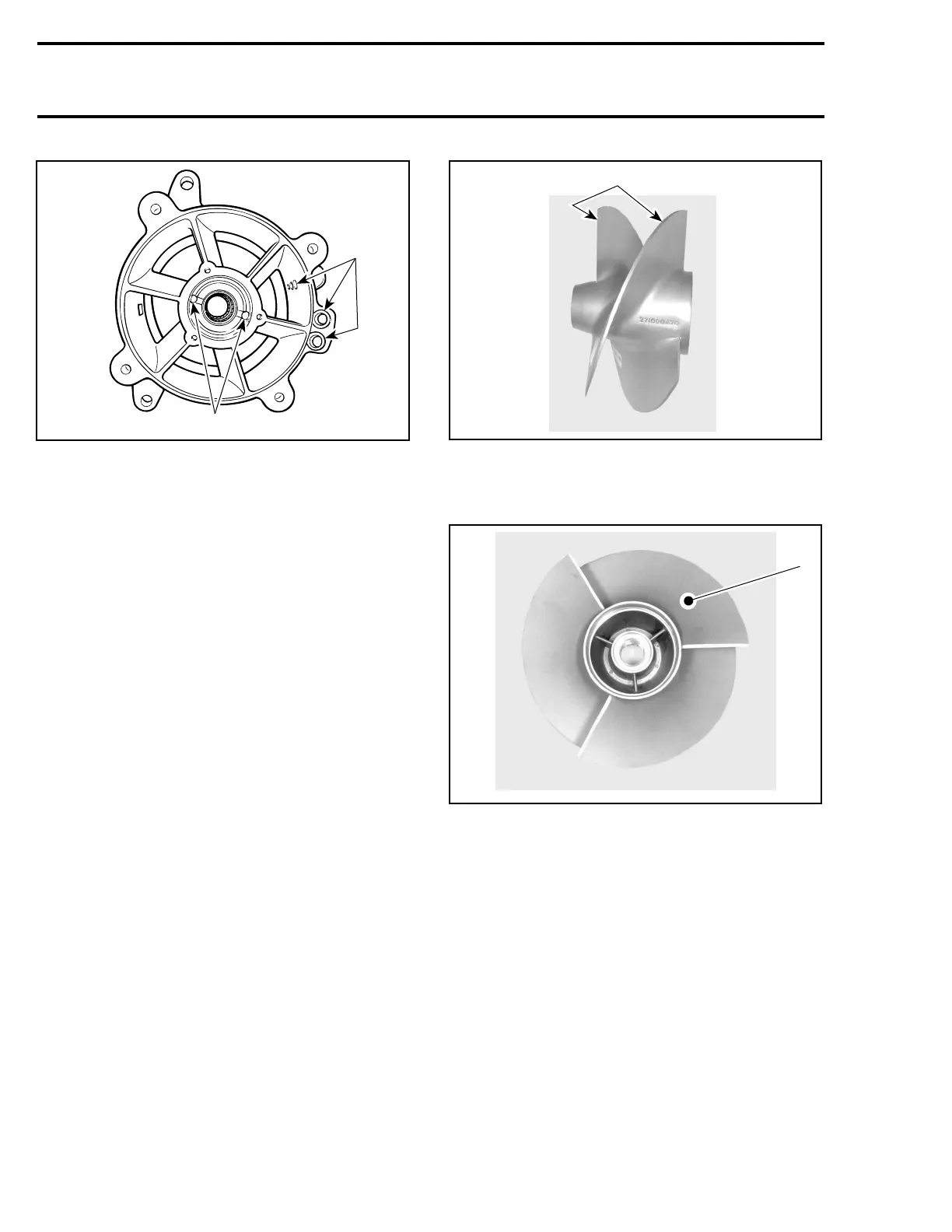

F01J13A

1

2

TYPICAL

1. Water passages

2. Oil passages

Brush and clean impeller shaft threads, impeller

and drive shaft splines with pulley flange cleaner

(P/N 413 711 809) or equivalent. Free threads and

splines from any residue.

CAUTION: Be careful not to damage impeller

shaft diameter.

PARTS INSPECTION

Impeller

Visually inspect impeller splines. Check for wear

or deformation. Renew parts if damaged.

NOTE: Check also PTO flywheel and drive shaft

condition. Refer to BOTTOM END and DRIVE

SYSTEM.

Examine impeller in wear ring for distortion.

Check if blade tips are blunted round, chipped or

broken. Such impeller is unbalanced and will vi-

brate and damage wear ring, impeller shaft, shaft

seal or bearings. Renew if damaged.

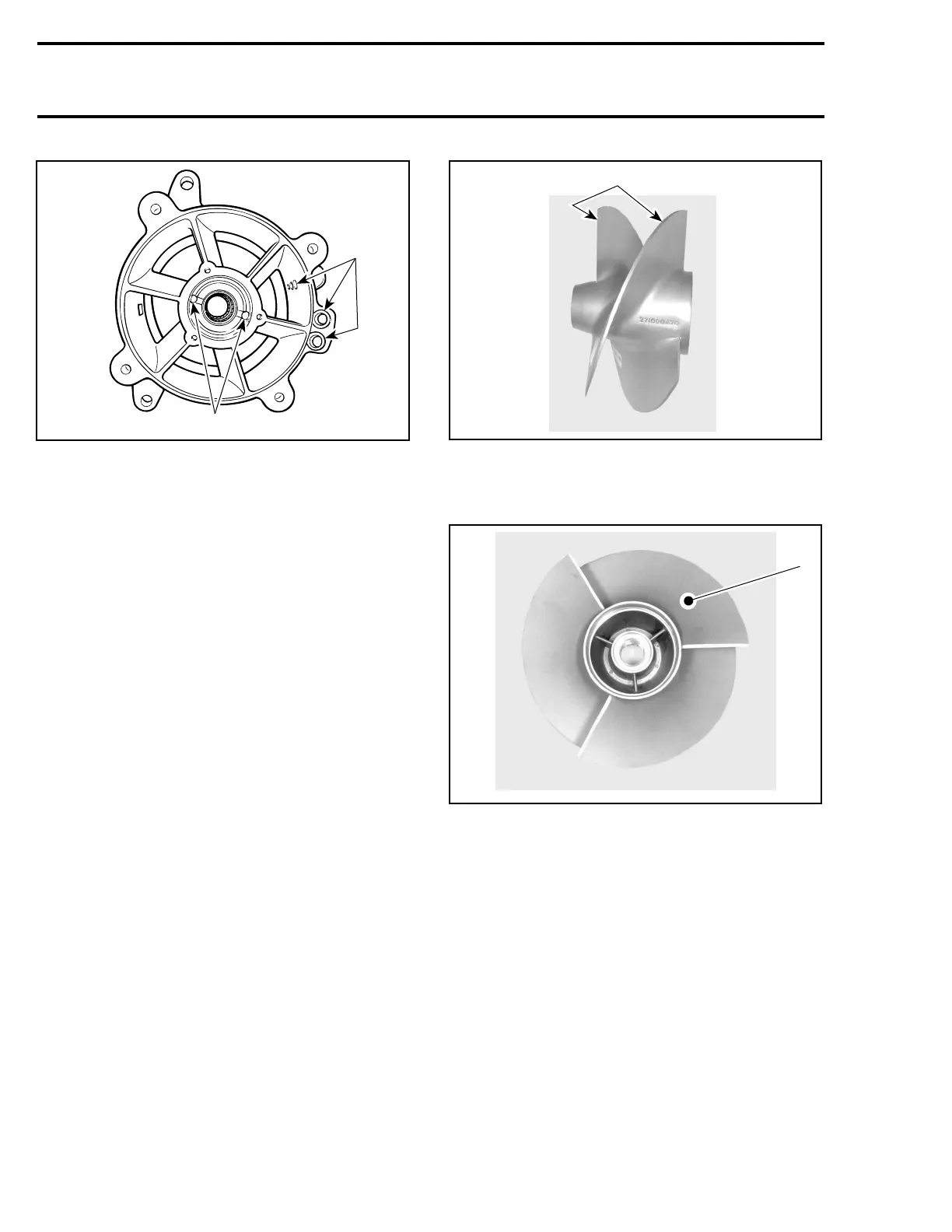

F02J0VB

1

1. Replaced if blunted round or damaged

Check impeller for cavitation damage, deep

scratches or any other damage.

F02J0UA

1

1. Check for cavitation, deep scratches or other damage

Wear Ring

Check wear ring no. 3 for deep scratches, irregular

surface or any apparent damage.

If impeller/wear ring clearance is too large and im-

peller is in good shape, renew wear ring.

Needle Bearing and Impeller Shaft

WEAR

Inspect needle bearings no. 16 and no. 17 and

their contact surface. Check for scoring, pitting,

chipping or other evidence of wear.

With your finger nail, feel contact surface of seal.

If any irregular surface is found, renew impeller

shaft no. 13.

240 smr2005-062

Loading...

Loading...