Section 07 ELECTRICAL SYSTEM

Subsection 01 (IGNITION SYSTEM)

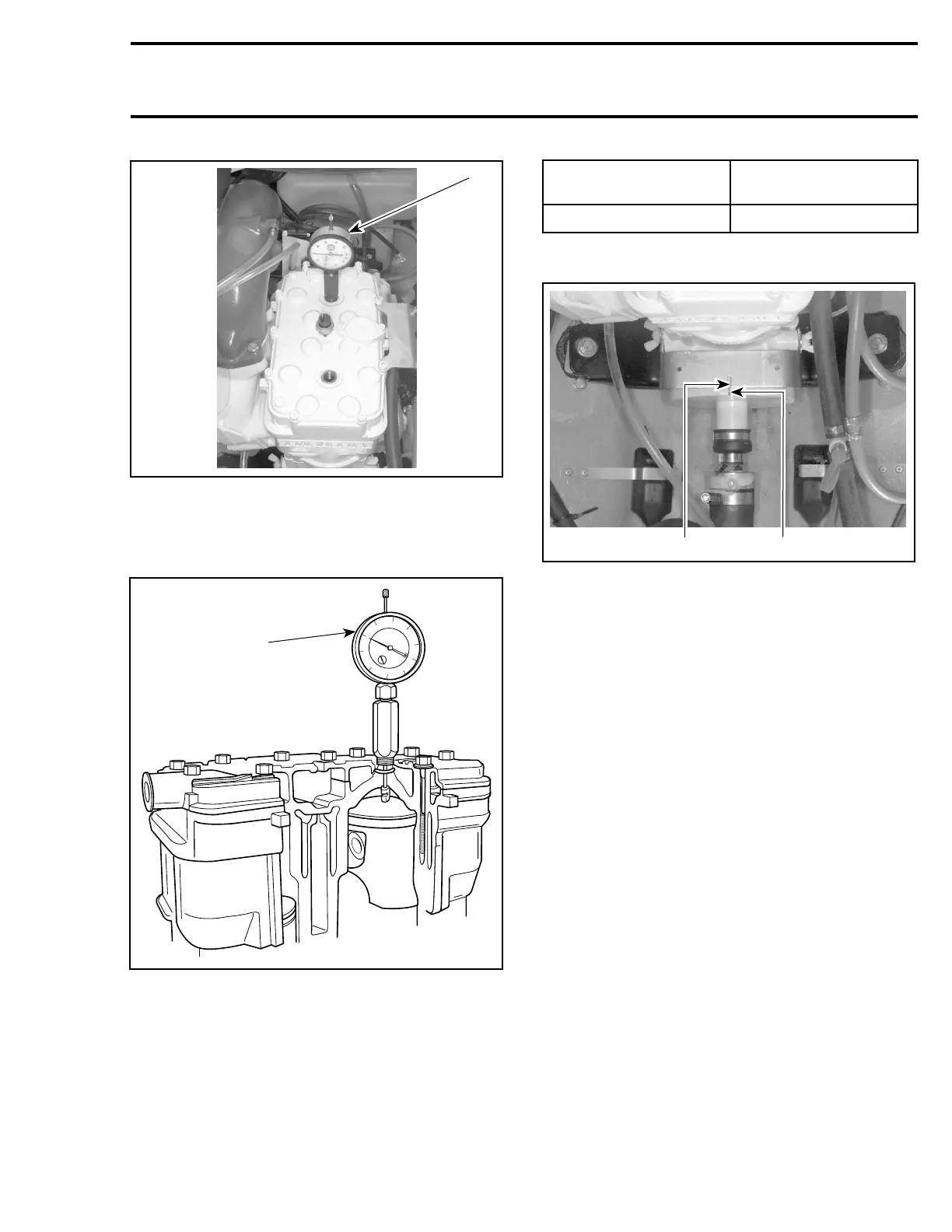

F01H5TA

1

TYPICAL

1. TDC gauge on MAG side

– Rotate PTO flywheel counterclockwise (when

facing it) until piston is at top dead center.

90

80

70

60

50

40

30

20

10

0

1

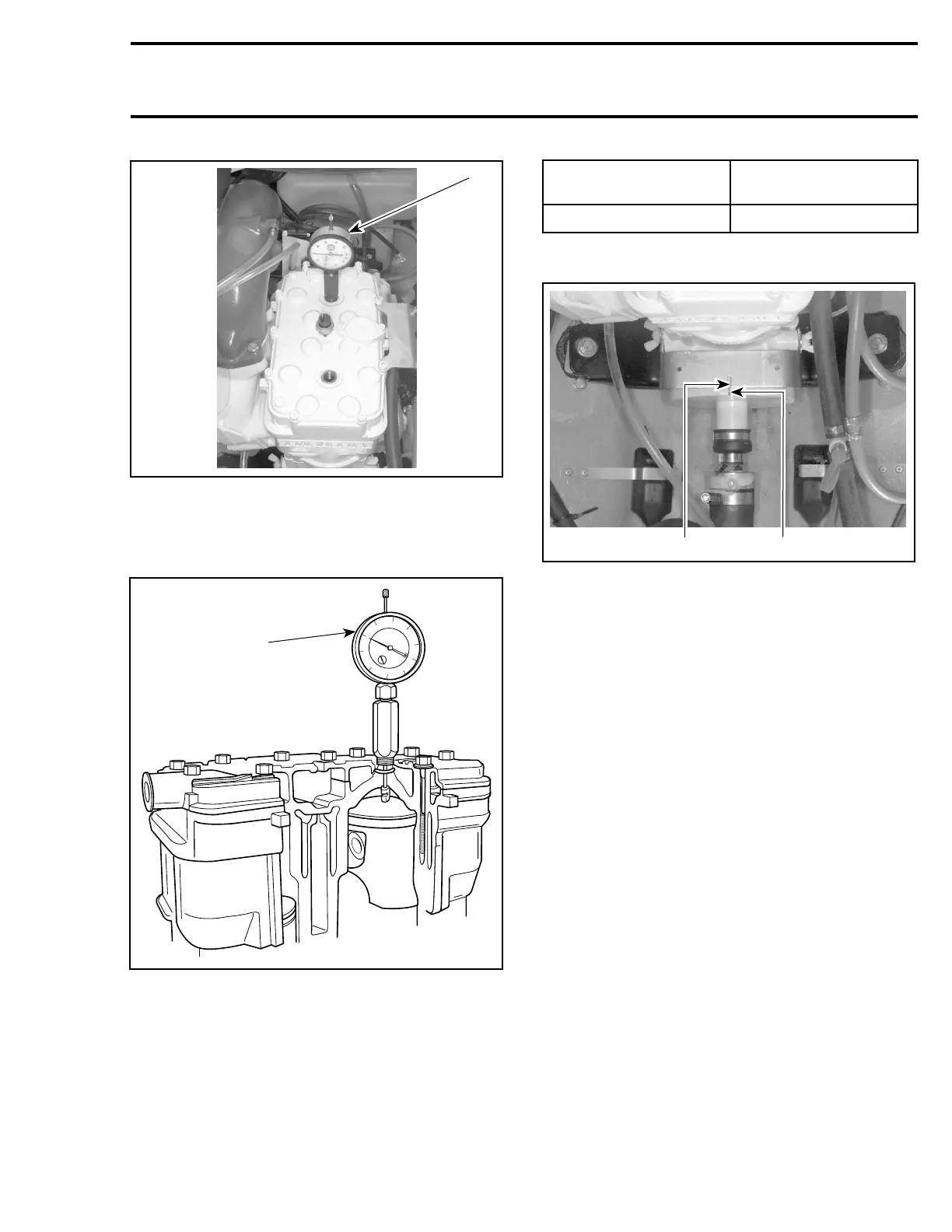

F01H4LA

TYPICAL

1. Adjust gauge dial at zero

– From this point, rotate flywheel clockwise to

reach proper specification according to engine.

Refer to the following chart.

ENGINE

IGNITION TIMING

(BTDC)

717

2.59 mm (.102 in)

– Scribe a thin mark on PTO flywheel in the mid-

dle of tool slot.

F01H5SB

1

2

TYPICAL

1. Tool slot

2. Flywheel mark

NOTE: This mark becomes the reference when

verifying the ignition timing (dynamic test).

– Remove TDC gauge.

– Reinstall spark plug and connect wire.

Ignition Timing Verification

(Dynamic Test)

To check ignition timing, use a timing light (avail-

able at local facilities).

NOTE: Ensure to use a timing light capable to

work with 2-stroke engines and rated up to 6000

RPM. Otherwise, an inaccurate reading will be ob-

tained.

The ignition components are affected by tempera-

ture variation, therefore, timing must be checked

when engine is cold, after idling for a MAXIMUM

of 20 seconds.

– Connect an induction-type tachometer (P/N 529

014 500) to spark plug wire.

smr2005-057 147

Loading...

Loading...