Section09PROPULSION

Subsection 02 (DRIVE SYSTEM)

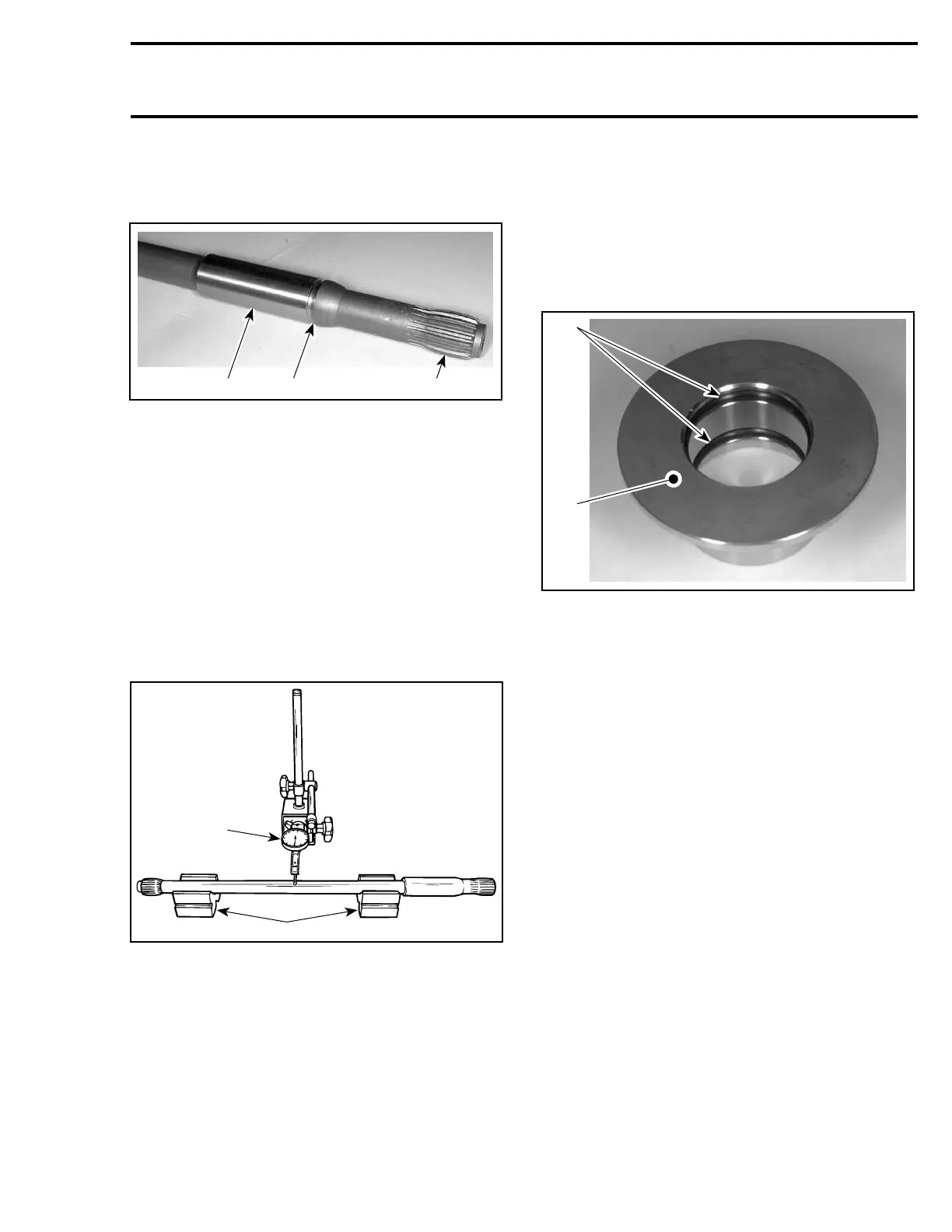

With your finger nail, feel machined surface of

drive shaft. If any irregular surface is found, re-

new drive shaft.

F01I0FA

321

TYPICAL

1. Surface condition

2. Groove condition

3. Splines condition

Excessive deflection could cause vibration and

damage to drive shaft splines, impeller, flywheel

or seal carrier.

Place rear drive shaft on V-blocks and set-up a dial

gauge in center of shaft. Slowly rotate shaft; dif-

ference between highest and lowest dial gauge

reading is deflection. Refer to the following illus-

tration.

Maximum permissible deflection is 0.5 mm

(.020 in).

1

2

F01J15A

MEASURING DRIVE SHAFT DEFLECTION

1. Dial gauge

2. V-blocks

Front Drive Shaft

Check condition of front drive shaft no. 13.

Check condition of couplers.

Replace front drive shaft if necessary.

Damper

Visually inspect shape of damper no. 24 for defor-

mation or other damage.

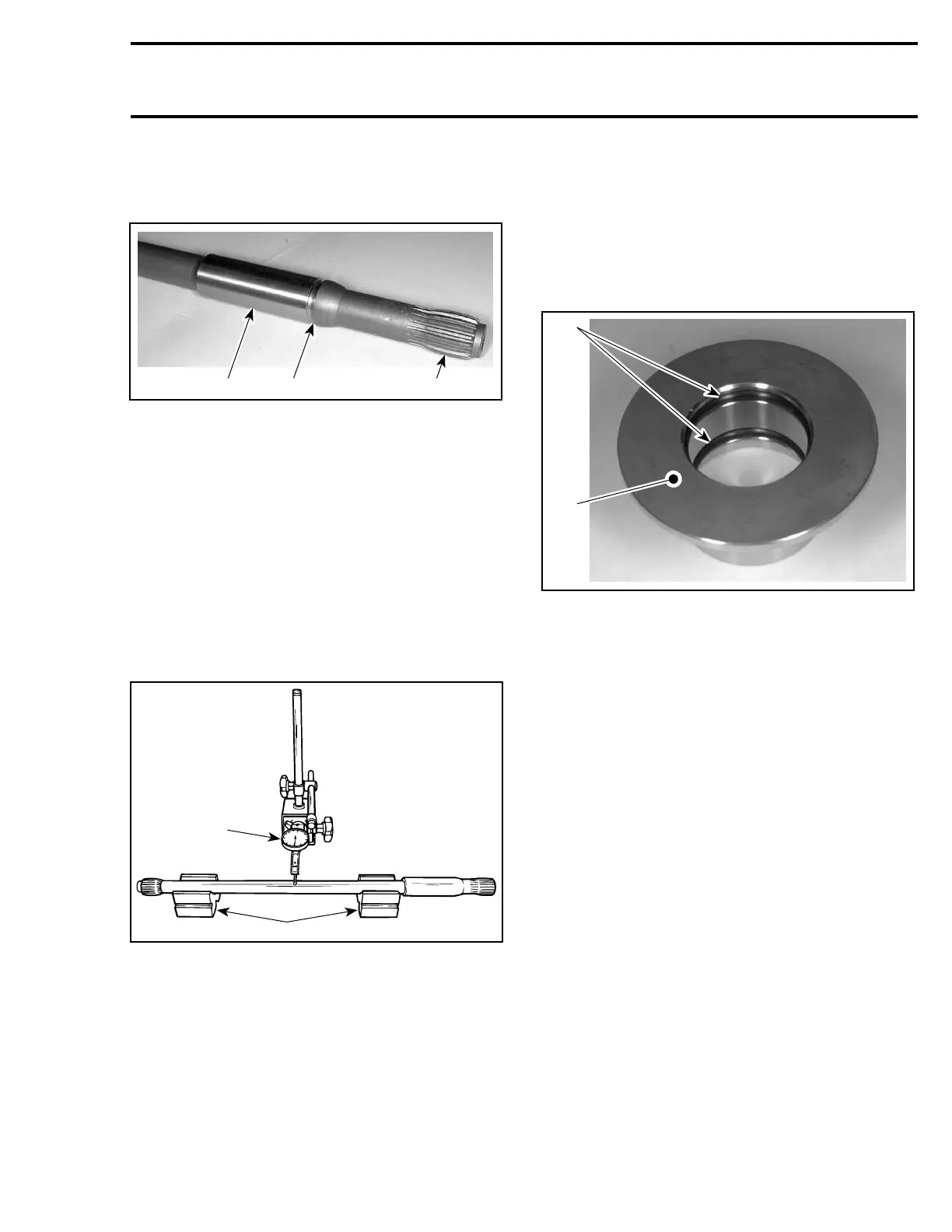

Floating Ring and O-Ring

Inspect condition of O-rings no. 25 and contact

surface of floating ring no. 6.

F01I0GA

1

2

1. O-rings

2. Floating ring contact surface

Boot

Inspect the condition of boot no. 7.Ifthereisany

damage or evidence of wear, replace it.

To verify the preload of the boot no. 7, proceed as

follows:

NOTE: To verify the boot preload and free length,

jet pump and drive shaft must be installed.

Measure boot length when normally installed on

drive shaft. Ensure circlip no. 8 is properly in-

stalledintogroove.

smr2005-063 261

Loading...

Loading...