The following machine data is first checked and set:

● MD32200 $MA_POSCTRL_GAIN = 0

● MD32610 $MA_VELO_FFW_WEIGHT = 1

● MD32620 $MA_FFW_MODE = 3

●

MD32810 $MA_EQUIV_SPEEDCTRL_TIME = as tuned

The following examples show the effects of different jerk values on the positioning of an axis.

Examples

The MD32431 axis machine data is used to set the jerk.

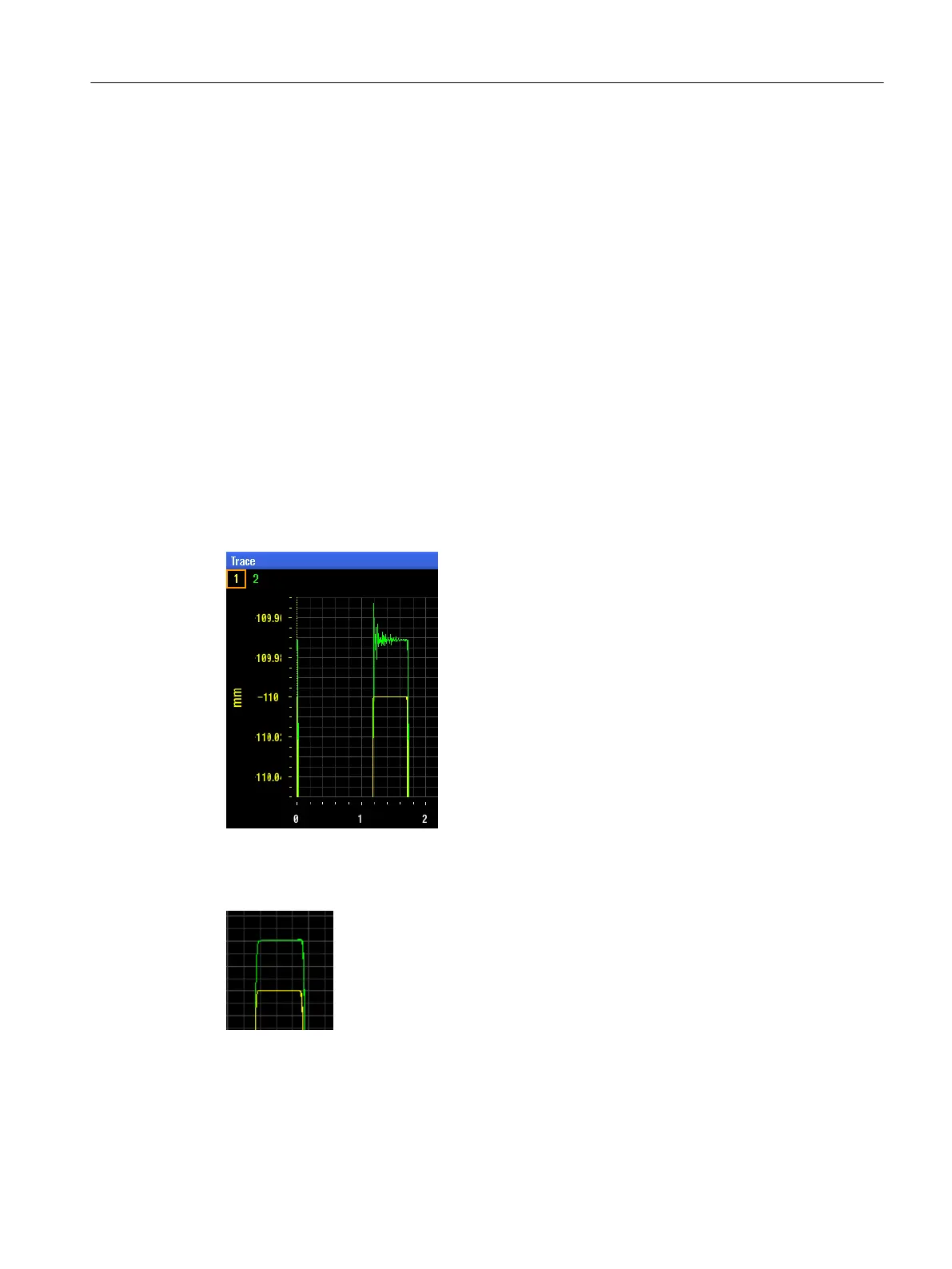

Example 1: MD32431 $MA_MAX_AX_JERK = 600 ⇒ jerk too high.

1. Restart the trace and then execute the part program.

2. Press the "Start trace" softkey and then the <RESET> and <CYCLE START> keys.

3. Correct the overshoot by increasing MAX_AX_JERK.

This diagram shows the jerk increase until an overshoot caused by the mechanical system.

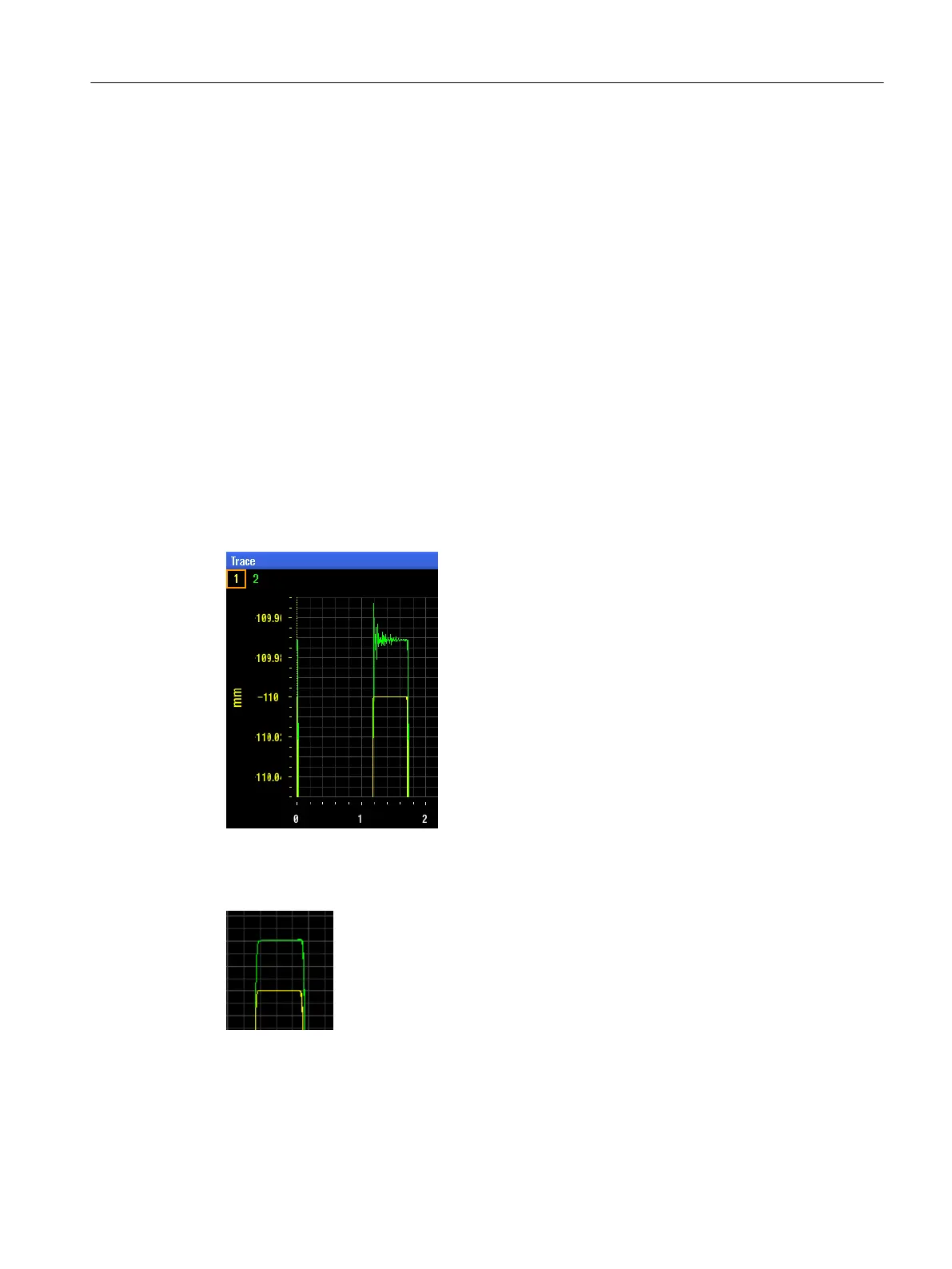

Example 2: MD32431 $MA_MAX_AX_JERK = 2 ⇒ jerk too low.

A jerk that is too low causes the positioning contour to be rounded.

Example 3: MD32431 $MA_MAX_AX_JERK = 65 ⇒ jerk tuned.

If the jerk is tuned, there is no overshoot or it is small and the positioning contour is sharp.

Tuning

6.3 Optimizing the axis jerk

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 189

Loading...

Loading...