Result

The best contour results are achieved when the circular form test results are in the correct

actual size, shape and minimum p/p deviation between a combined interpolation of the axes

(X-Y, X-Z, Y-Z).

An NC program in the MDA operating mode and the circularity test function are used to

measure and evaluate these

results. The "worst case" of a circle radius and the path velocity

must lead to a realistic radial acceleration of which the machine is capable.

Machine manufacturers generally have specifications for the radius and feedrate test circuit.

Circularity tests of machine manufacturers usually use a radius of 100 mm or 150 mm with

feedrate speeds that are determined by the machine manufacturer. The machine manufacturer

determines the specifications for an acceptable result.

High-speed processes generally have higher requirements for testing circles with high-speed

milling machines and can range from circle radii of 10 - 25 mm and feedrates of 5 - 10 m/min.

For high-speed milling machines, the results are generally acceptable if the P/P deviation ≤

0.010 mm and the actual size of the circle is equal to the programmed radius, and in the worst-

case scenario to the path velocity.

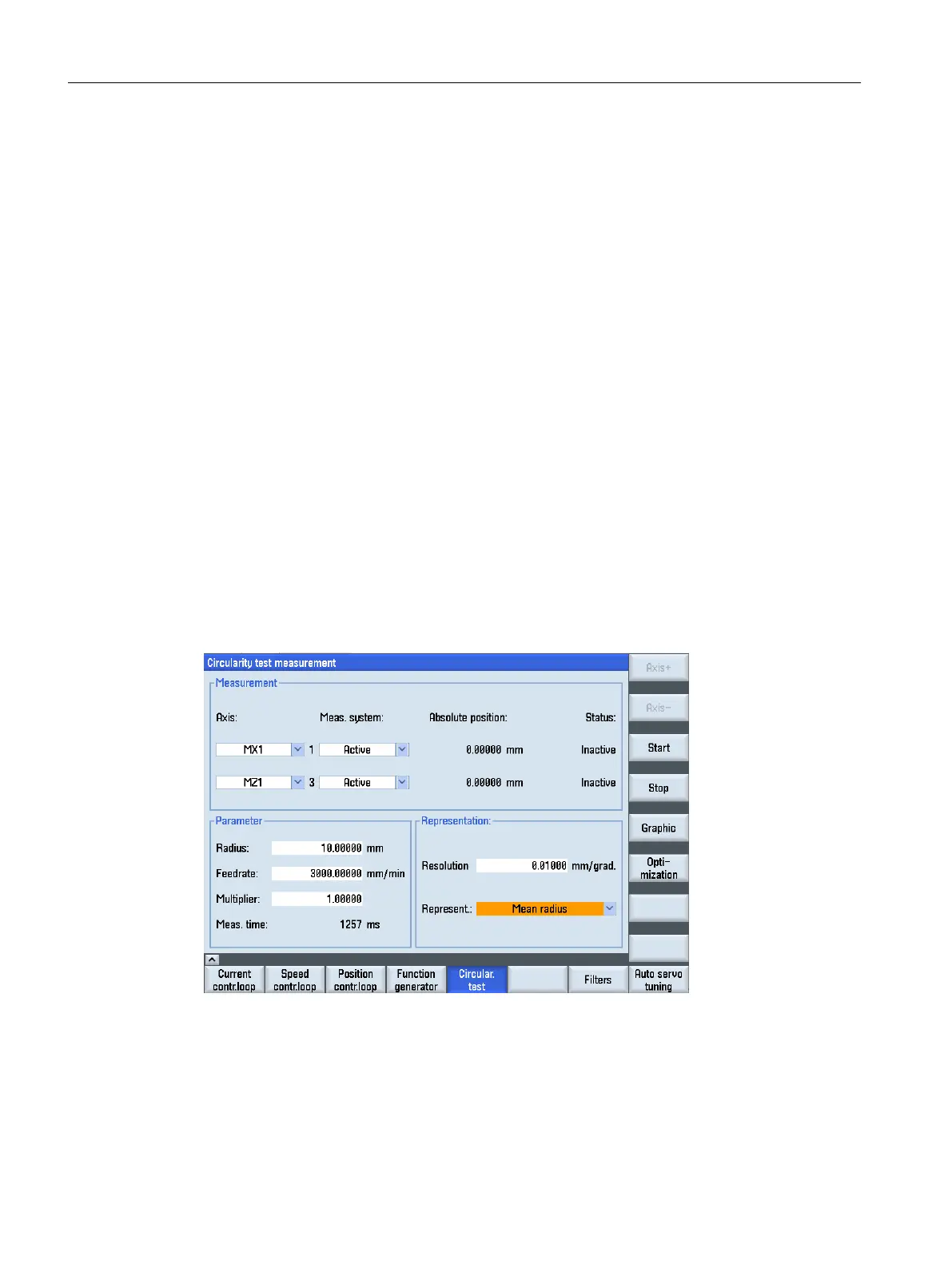

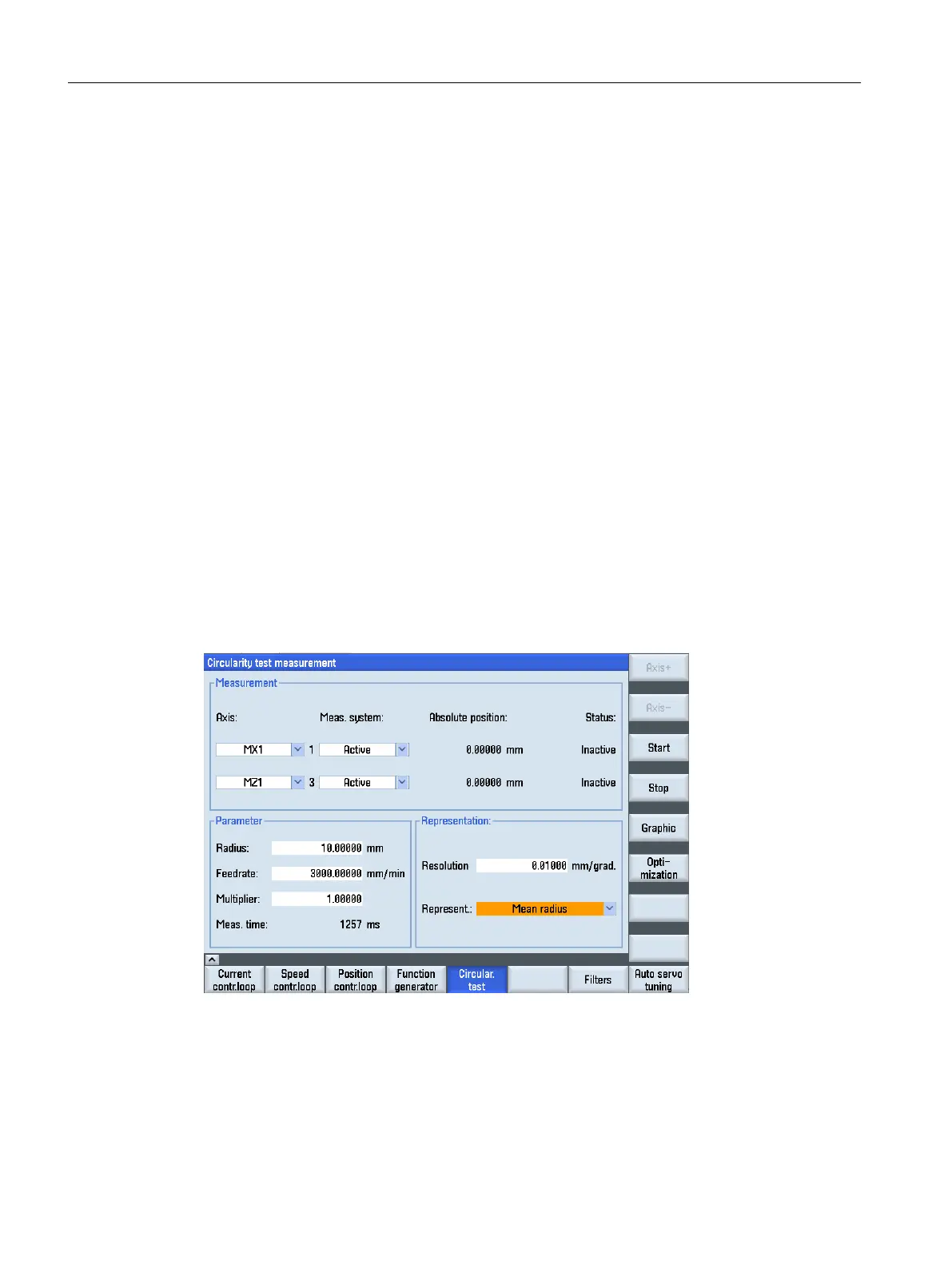

6.6.2 Circularity test: Performing the measurement

Setting parameters

Tuning

6.6 Circularity test

CNC commissioning

206 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...