9.3.1 Relocating, unloading, loading tool, positioning magazine

Tool and magazine movements

Per loading point there is one interface for:

● Jobsfor loading, unloading and relocating a tool (MVTOOL) and for magazine positioning

(POSM).

Message to the PLC user program:

– Job active

– Job specification

– Job description

The

jobs appear on the interface of the loading point from which the tool is to be exchanged.

● Acknowledgments of the PLC user program

All acknowledgments for a job must take place in the interface of the same loading point.

Acknowledgment errors should also be reset in this interface.

● Feedback signal from the tool management to the PLC user program

Message to the PLC user program:

– Status of acknowledgment

– Error status

– Map of the acknowledgment bits

● Job status

Selected data from the last intermediate or end acknowledgment is saved. This data is

needed by the PLC firmware for the next acknowledgment to the tool management and is

readable for diagnostic purposes. This data can be used by the user program to restart

after an abort (e.g. reset during a tool change).

All acknowledgments for a job must take place in the interface of the same loading point.

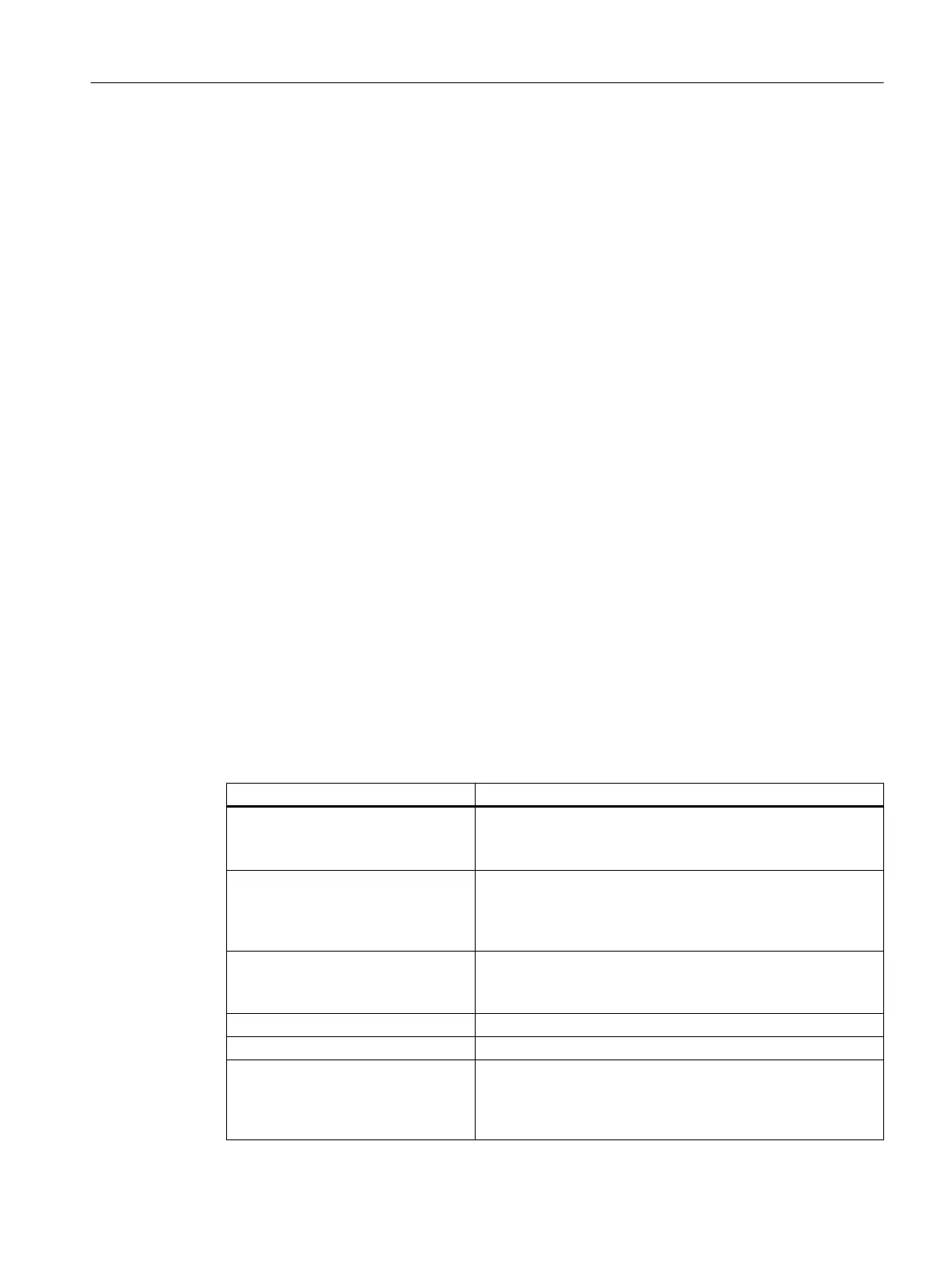

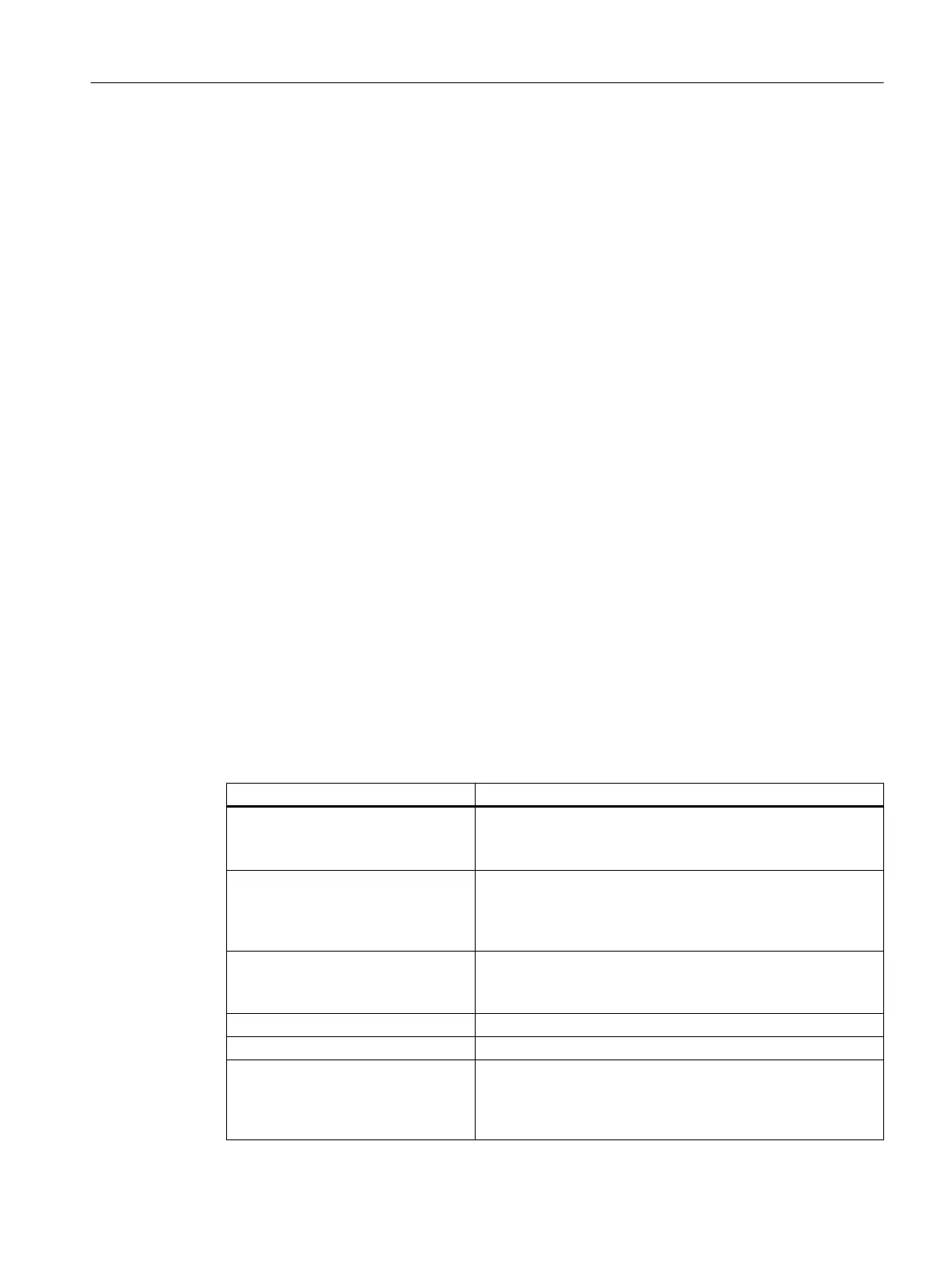

Interface signal Meaning

DB40xx.DBXy000.0 – DBXy003.6 PLC user program:

Acknowledgments for loading/unloading/relocating or position‐

ing the magazine

DB40xx.DBXy009.0 PLC user program:

Resetting the message "Acknowledgment error" /

DB41xx.DBX100.1) and the diagnostic information in the feed‐

back interface

DB41xx.DBXy000.0 Tool management:

Job for loading/unloading/relocating or positioning the maga‐

zine

DB41xx.DBBy001 Tool management: Job specification

DB41xx.DBWy006 – DBWy034 Job description

DB41xx.DBXy100:0

DB41xx.DBXy100.1

Positive feedback: Acknowledgment status, acknowledgment

OK, one PLC cycle pending

Negative

feedback: Acknowledgment status,

acknowledgment

error, static pending

Tool management

9.3 NC ↔ PLC user interface

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 265

Loading...

Loading...