7.8 High Speed Cutting (HSC)

7.8.1

High speed settings: Configuring CYCLE832

Function

The High Speed Settings function (CYCLE832) is used to preset data for the machining of

sculptured surfaces so that optimum machining is possible. The call of CYCLE832 contains

three parameters:

●

Tolerance

●

Machining type (technology)

●

Input of the orientation tolerance

The 3rd parameter is significant only for machines with multi-axis orientation transformation

(TRAORI). By default, it is assigned the value 1.

Tolerance / orientation tolerance

The tolerance value for the linear axes (geometry axes) is transferred to the CNC with the NC

command CTOL. CTOL = root(3) * tolerance value.

Tolerance value = 0: Tolerance value (CTOL) is loaded from the following SDs:

SD55446 $SCS_MILL_TOL_VALUE_ROUGH Tolerance value for roughing CYCLE832

SD55447 $SCS_MILL_TOL_VALUE_SEMIFIN Tolerance value for semi-finishing CYCLE832

SD55448 $SCS_MILL_TOL_VALUE_FINISH Tolerance value for finishing CYCLE832

Example: CYCLE832(0,_ROUGH,1) → tolerance value from SD55446 is used.

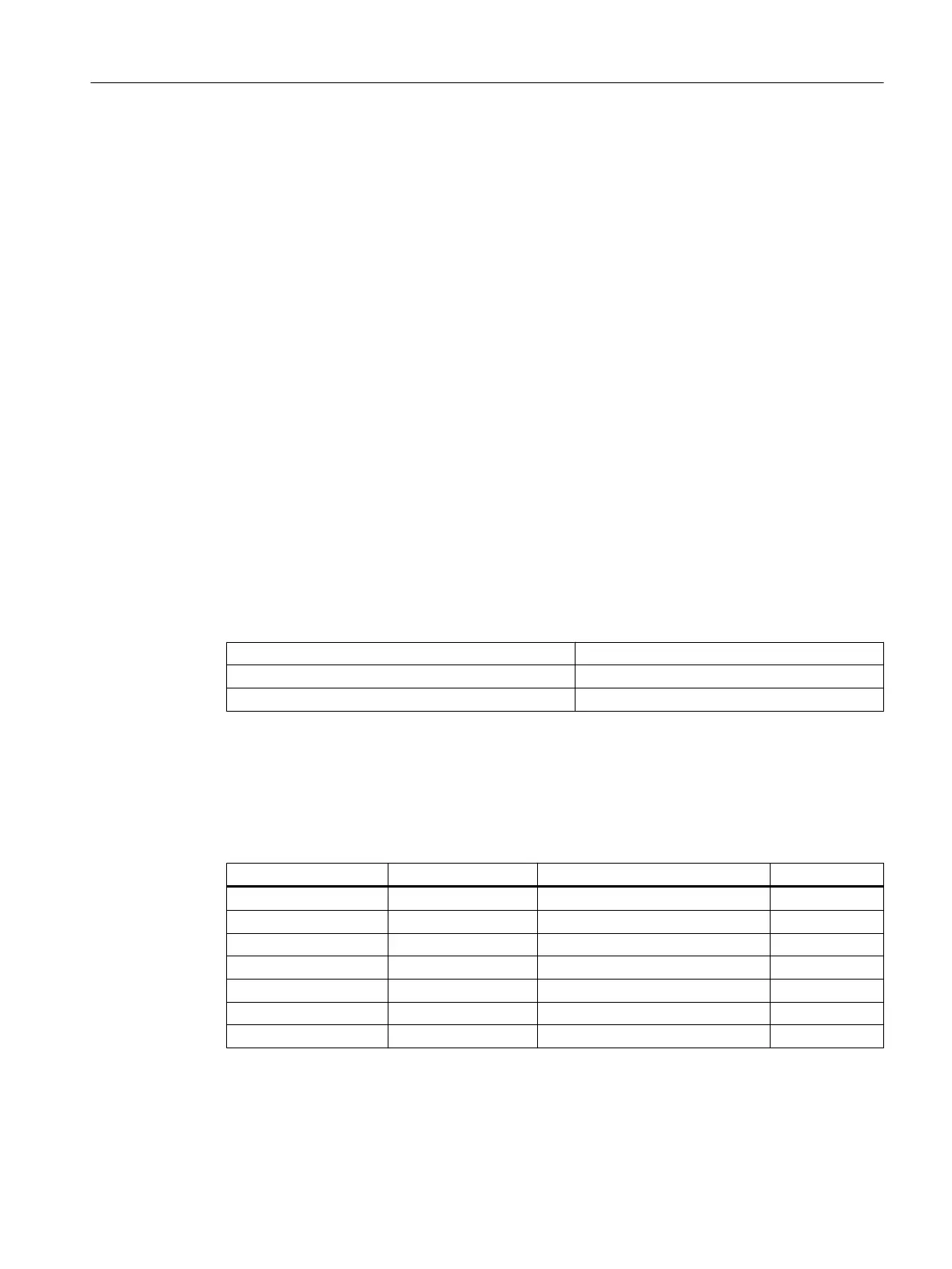

Machining type and technology G group 59

The machining types of the technology G group 59 are permanently assigned in CYCLE832

or in CUST_832.SPF:

Machining type Plain text Technology G group 59 Field index

Deselection _OFF DYNNORM 0

Roughing _ROUGH DYNROUGH 2

Rough-finishing _SEMIFIN DYNSEMIFIN 3

Finishing _FINISH DYNFINISH 4

Roughing

*)

_ORI_ROUGH DYNROUGH 2

Semi-finishing

*)

_ORI_SEMIFIN DYNSEMIFIN 3

Finishing

*)

_ORI_FINISH DYNFINISH 4

*)

With entry of an orientation tolerance

Configuring cycles

7.8 High Speed Cutting (HSC)

SINUMERIK Operate

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 167

Loading...

Loading...