6.5.3 Spindle: Checking the position controller

Testing the position controller

A test can now

also be performed to set the acceleration and jerk of the position control. This

test is performed by tapping without using a compensating chuck.

Procedure:

1. Check MD35550 $MA_DRILL_VELO_LIMIT[0] und [1]; the maximum velocity during

tapping.

2. Check SD55484 $SCS_DRILL_TAPPING_SET_MC[0] = 1;, it holds the spindle in the

positioning mode during tapping.

The following program can be used to drill ten holes at the same position:

SUPA D0 G0 G90 Z-200

FFWON

M19

SOFT

LAB:

G331 Z-214 S4000 K1

G332 Z-200 S4000 K1

REPEAT LAB P=9

M30

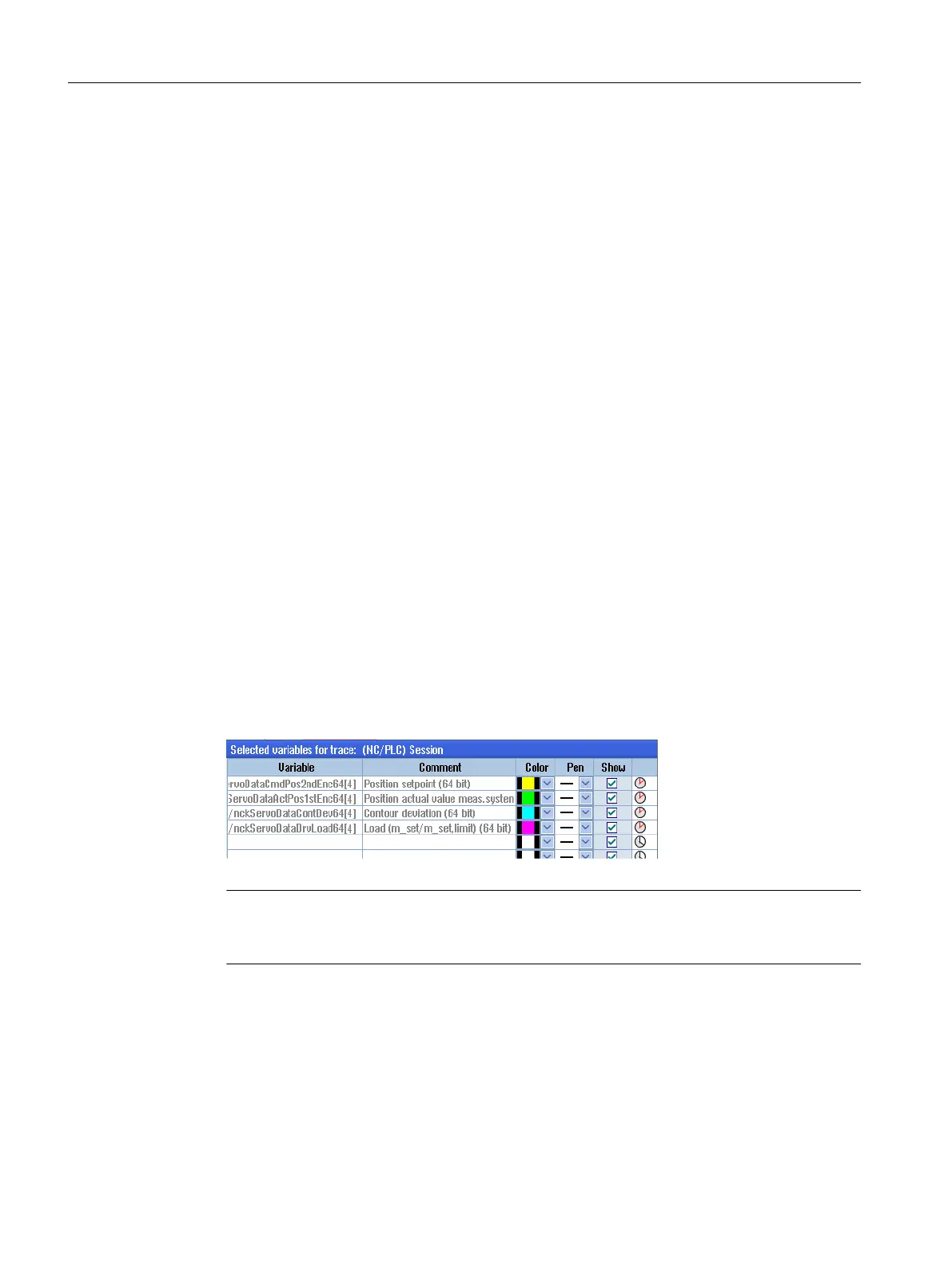

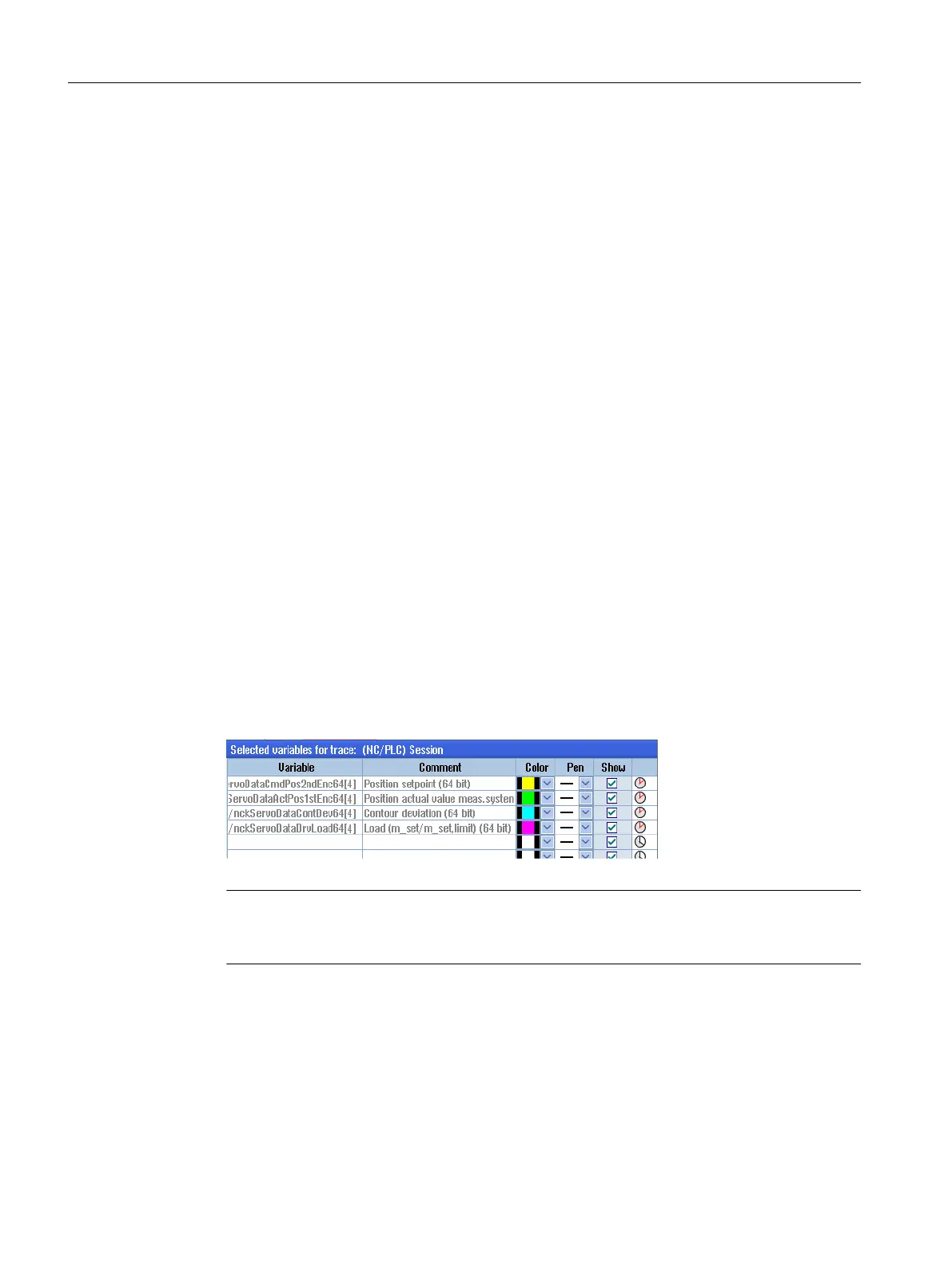

3. Select the following variables:

– Position setpoint (64-bit)

– Measuring system actual position (64-bit)

– Contour deviation (64-bit)

– Load (m_set/m_set_limit) (64-bit)

Note

Ensure that the correct signal is selected for the monitoring of measuring systems, e.g.

measuring system 1 or 2.

Tuning

6.5 Optimize the spindle

CNC commissioning

202 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...