Start PI Services in the NCK

area

Address Signal Values

Result DB1200.DBB5000.0 Job completed 1

DB1200.DBX5000.1 Error in job 0

DB410x.DBX0.0 delivers an order to relocate the tool from the buffer. The target location in

magazine 1 is in

DB4100.DBW12. With it, the PLC user program can execute the necessary

sequence.

9.7.8 Example: Repeat "Prepare tool change" order

Sequence: Repeat the job

For a milling machine with toolboy and shifter, the asynchronous transfer message and job

can cross:

● The toolboy was acknowledged to the tool management as the target position for the old

tool with the end acknowledgment.

● The part program is continued with the new tool and after a very short time needs the

previous (old) tool once more.

● The tool management generates the next preparation job for the tool change with the

toolboy as the source position for what will then be the new tool.

● At the same time the PLC user program transferred the tool from the toolboy to the shifter.

● The PLC user program communicates the tool movement from the toolboy to the shifter

asynchronously and starts onward transport to the magazine.

● In the next cycle the PLC user program recognizes the new job to relocate the tool from

the toolboy to the spindle.

There is no longer any tool in the toolboy. The PLC user program must detect such a condition

(monitoring: does toolboy or shifter contain a tool?). It can now cancel the return of the tool

into the magazine. A repeat job (Status 7) can then be requested from the tool management:

● Meanwhile, the tool management has received the message that the tool is in the shifter.

● The tool management generates a new preparation job with the source position shifter for

the new tool.

Note

The acknowledgment to repeat the job "Prepare tool change" may only be issued before

the end acknowledgment of the "Prepare tool change" job!

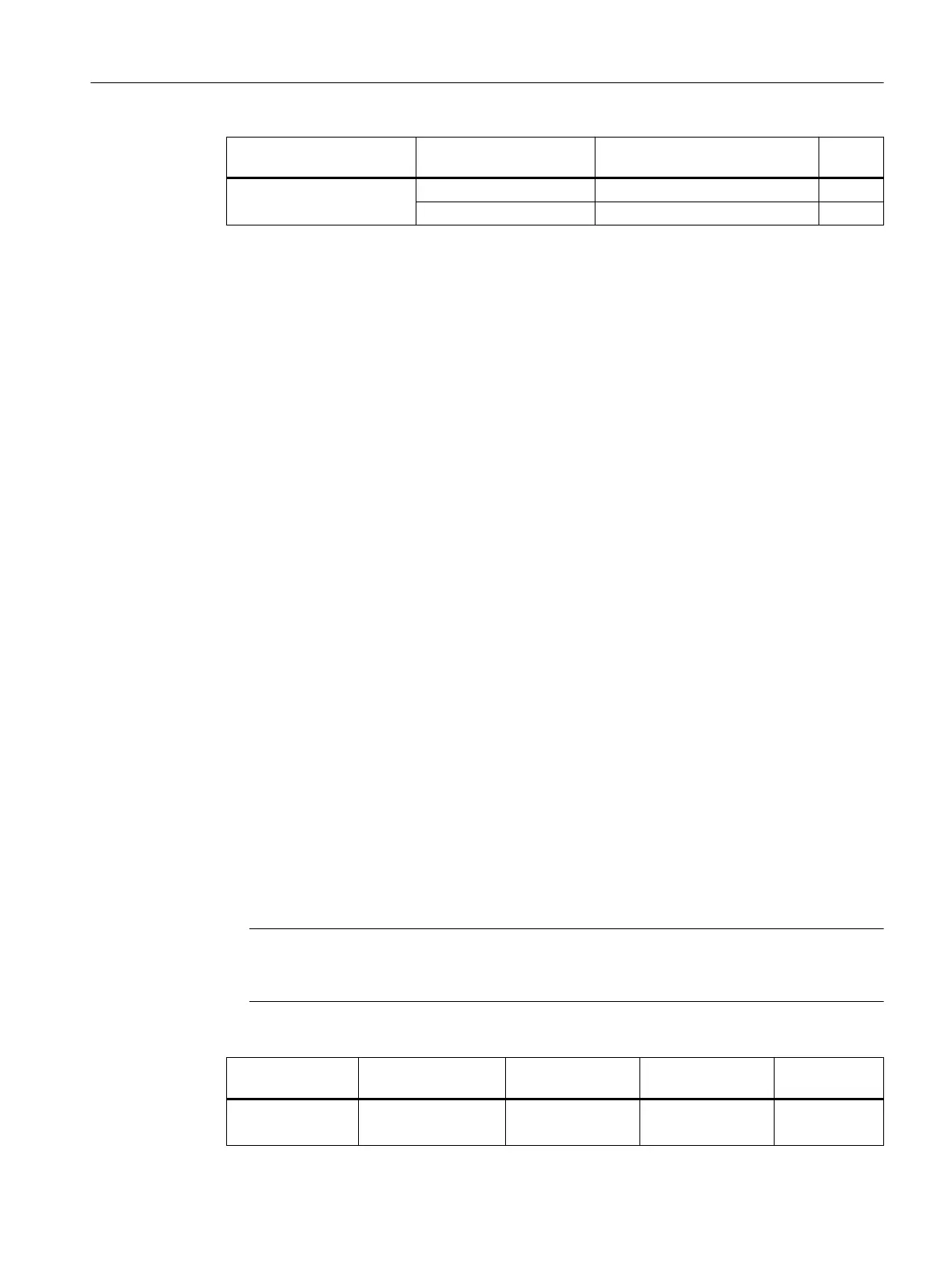

Acknowledgment to tool management:

Acknowledgment

step

Acknowledgment bit Transfer step new

tool

Transfer step old

tool

Status

xxx DB4000.DBXx.x

0 0 7

Tool management

9.7 Application example for turning machine

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 315

Loading...

Loading...