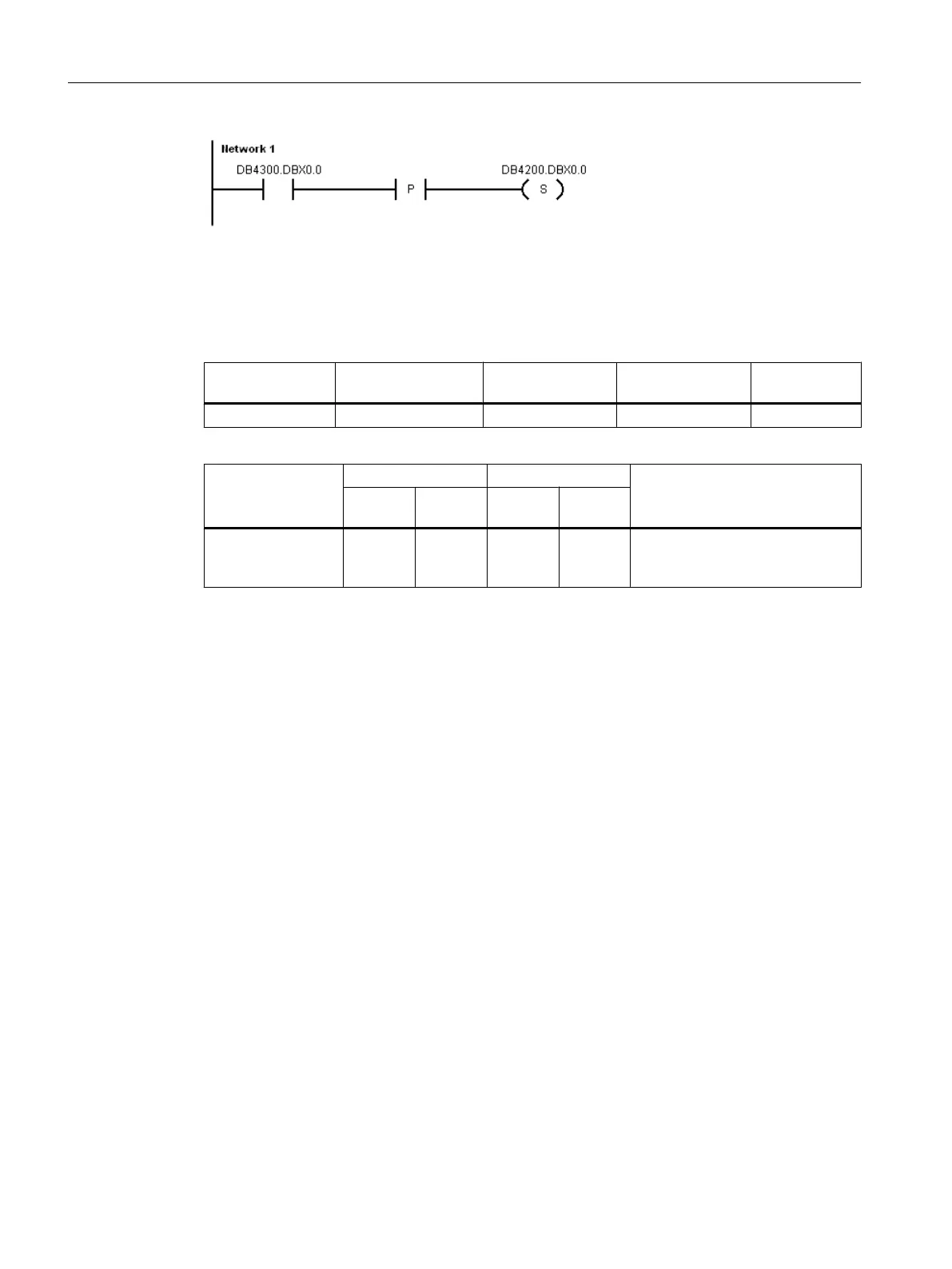

Figure 9-5 Programming in PLC user program

An

asynchronous

message

can

be used for magazine movements without a job from the tool

management.

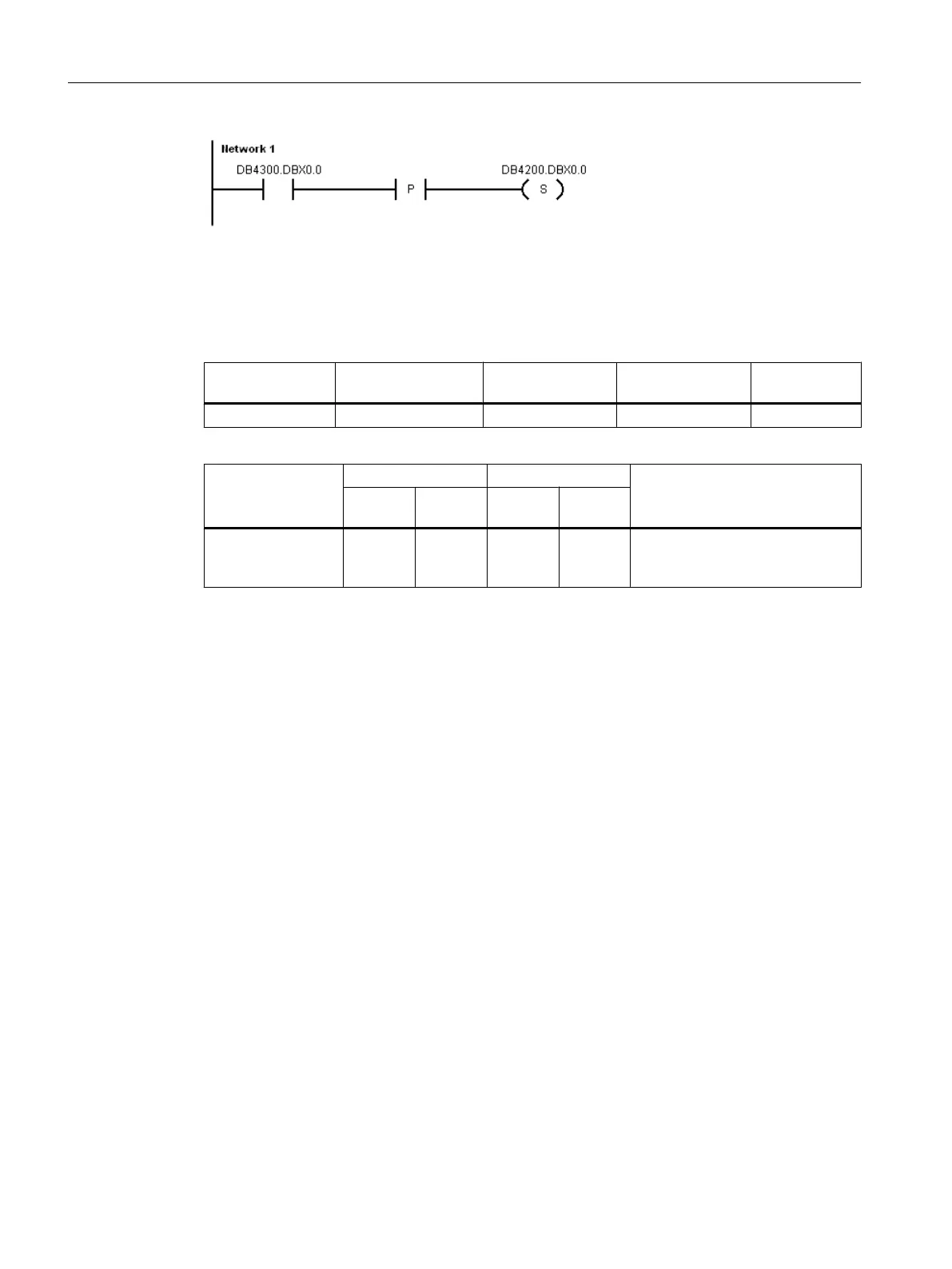

Acknowledgment to tool management:

Acknowledgment

step

Acknowledgment bit Transfer step new

tool

Transfer step old

tool

Status

xxx DB4000.DBXx.x 101 0 204

Transfer step Source Objective Comment

Maga‐

zine

Location Maga‐

zine

Location

101

DB9901.DBW0

1 n 9998 1 The variable location in Magazine

1 is positioned at the changing

point to the spindle.

n is the actual location number (n ≠ 0) to be entered by the PLC user program in the variable transfer

table.

9.7.3 Example: Tool change cycle for turning machine

Transfer variables of the T replacement cycle:

The "Replacement tools for tool management" option is not active.

Prerequisite is that the tool management has been informed of each magazine movement.

With MD10717:

$MN_T_NO_FCT_CYCLE_NAME (name of the cycle that should be executed

instead of the T function, e.g. "TCHANGE"), you can set that a cycle is run through when the

T command is called. The cycle is run through at every T call, irrespective of whether a new

tool or the already active tool is called. The position of the turret can be set on the programmed

tool in this cycle (POSM). This is necessary when the turret has been positioned manually after

a tool selection and the tool has not been deselected. In this case, the NC does not issue a

new job for tool change at the interface.

Tool management

9.7 Application example for turning machine

CNC commissioning

310 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...