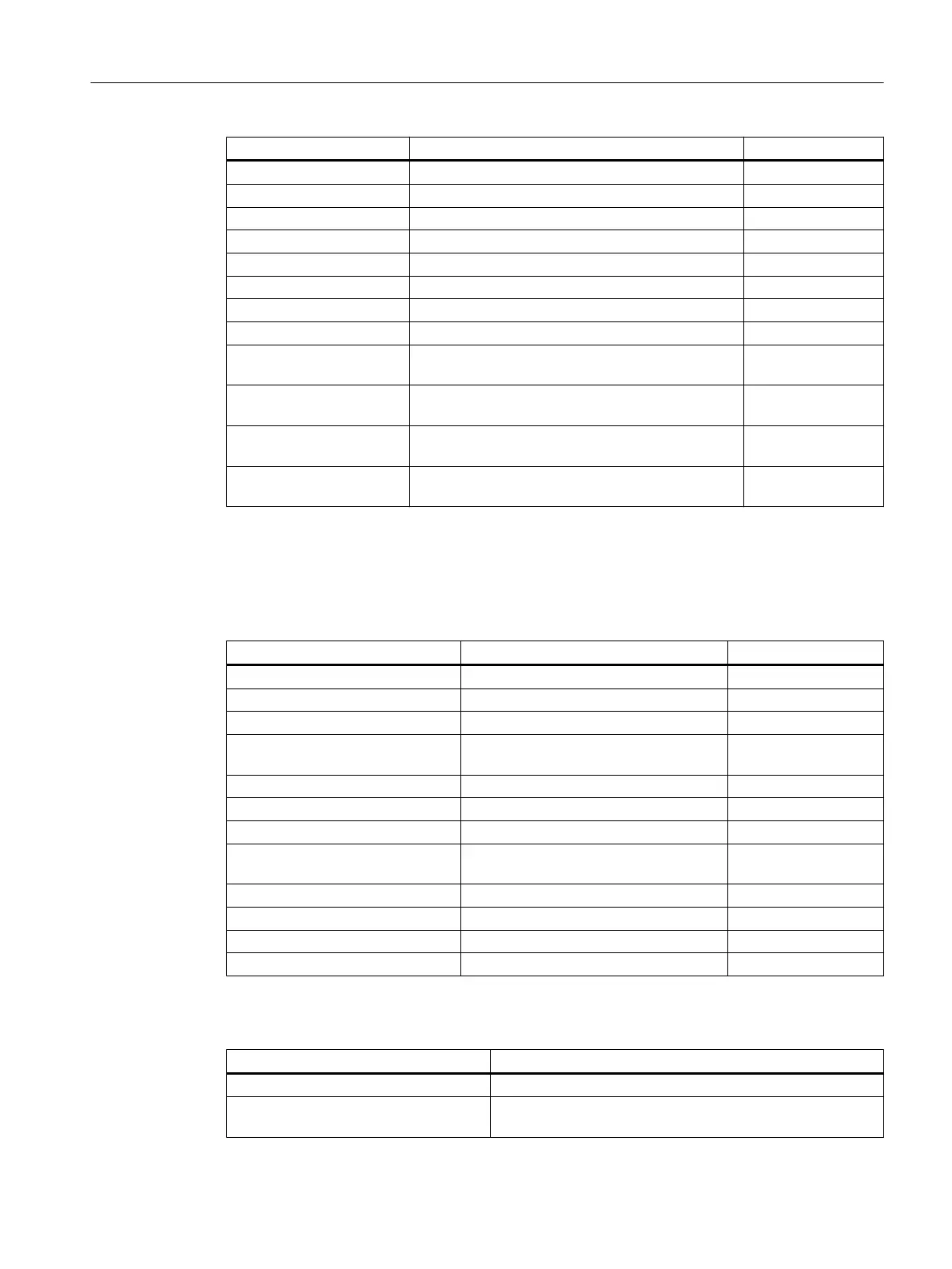

Identifier Parameter or property System variable

*)

SupWarningPieces Prewarning limit for workpiece count $TC_MOP3

SupRemainingPieces Actual value for workpiece count $TC_MOP4

SupDesiredTime Setpoint for tool life $TC_MOP11

SupDesiredPieces Setpoint for workpiece count $TC_MOP13

SupWarningWear Prewarning limit for wear $TC_MOP5

SupRemainingWear Actual value for wear $TC_MOP6

SupDesiredWear Setpoint for wear $TC_MOP15

SupExtendedAlarm PLC tool management: Extended alarm -

SupWarningPiecesIncre‐

mental

PLC tool management: Prewarning limit for work‐

piece count

$TC_MOP13 -

$TC_MOP3

SupActualPieces PLC tool management: Actual value for workpiece

count

$TC_MOP13 -

$TC_MOP4

EdgeSupUser_1, ...

EdgeSupUser_10

OEM cutting edge monitoring parameters 1 to 10 $TC_MOPC1, ...

$TC_MOPC10

EdgeSupAppl_1, ... Edge‐

SupAppl_10

Siemens application cutting edge monitoring pa‐

rameters 1 to 10

$TC_MOPCS1, ...

$TC_MOPCS10

*)

Parameter corresponds to the

system variable or the system variable is the basis for this parameter.

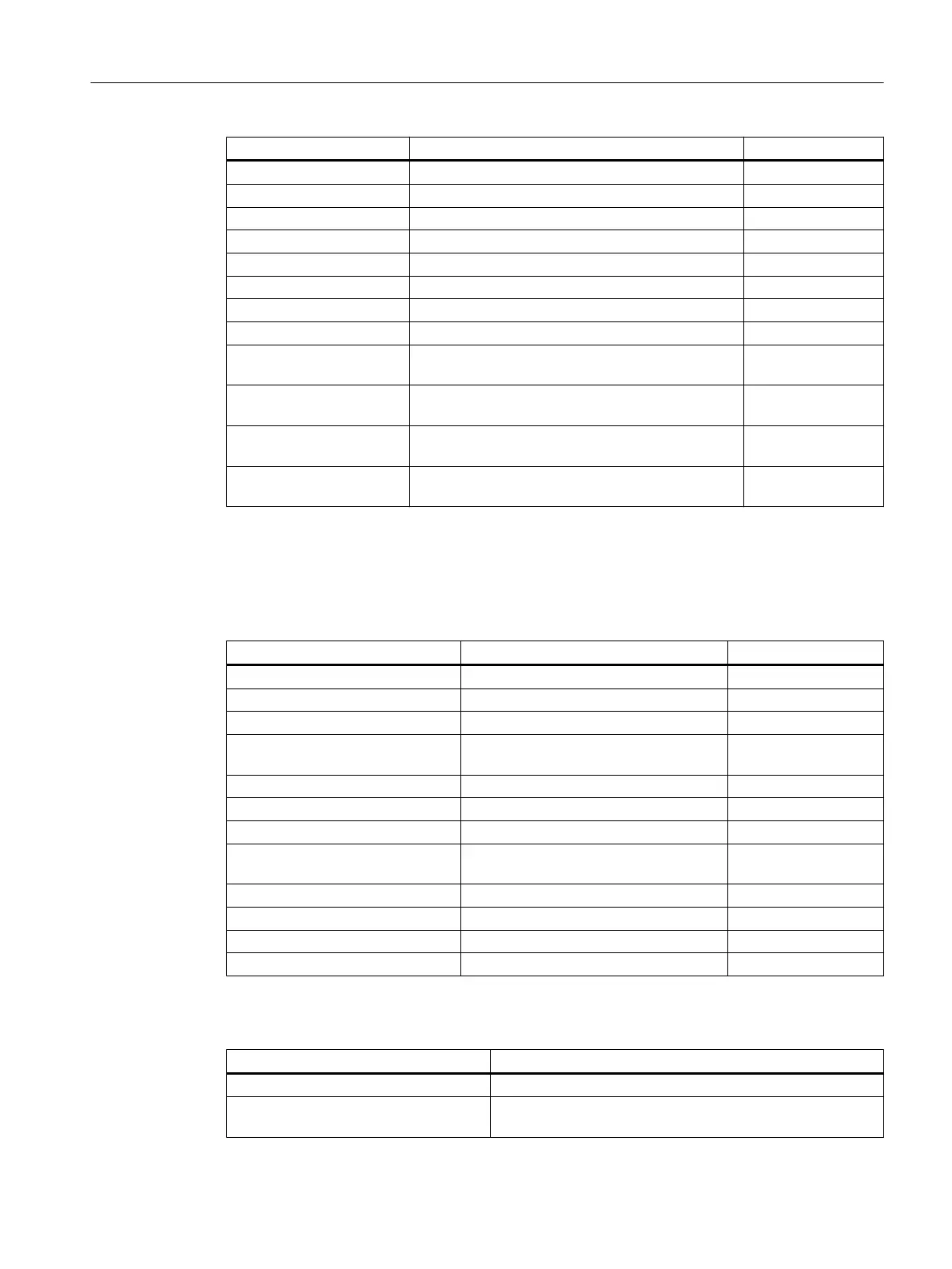

9.2.2.4 Grinding parameter identifiers

For grinding parameters, the following identifiers are used in the configuration file:

Identifier/parameter Meaning System variable

*)

GrindingSpindleNo Spindle number $TC_TPG1

GrindingConnectionRule Chaining rule $TC_TPG2

MinimalDiscRadius Minimum grinding wheel radius $TC_TPG3

ActualDiscRadius Actual grinding wheel radius (read ac‐

cess only)

-

MinimalDiscWidth Minimum grinding wheel width $TC_TPG4

ActualDiscWidth Actual grinding wheel width $TC_TPG5

MaximalDiscSpeed Maximum grinding wheel speed $TC_TPG6

MaximalDiscPeripheralVelocity Maximum grinding wheel peripheral ve‐

locity

$TC_TPG7

AngleBevelDisc Angle of inclined wheel $TC_TPG8

ParamForRadiusCalculation Parameters to calculate the radius $TC_TPG9

Directory of the dressing program $TC_TPG_DRSPATH

Dressing program name $TC_TPG_DRSPROG

*)

Parameter corresponds to the

system variable or the system variable is the basis for this parameter.

The following parameters are assigned to the cutting edges of the grinding tool:

Identifier/parameter Meaning

GrindingMonitoring Grinding-specific tool monitoring

GrindingUseBaseLength Taking into account the basis dimension when calculating

the grinding wheel radius

Tool management

9.2 Configuring the user interface

SINUMERIK Operate

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 245

Loading...

Loading...