7.9.3 Measuring in the JOG mode

Preconditions

You have already made the settings from the previous section "Measuring cycles and

measurement functions, general (Page 170)".

Workpiece measurement

For milling:

●

The probe has been inserted in the tool spindle.

● The probe has been selected in the tool list as type 7xx (probe).

● The probe is activated as tool in the current NC channel.

Tool measurement

To measure tools, an appropriate probe must be located in the machine space so that this can

be reliably and safely reached with a tool in the spindle.

The following tool types are supported with the tool measurement:

● Milling technology: Tool types 1xx and 2xx

● Turning technology: Tool type 5xx, 1xx, 2xx

For the specified tool types, the tool lengths and the tool radii can be measured.

Setting general data

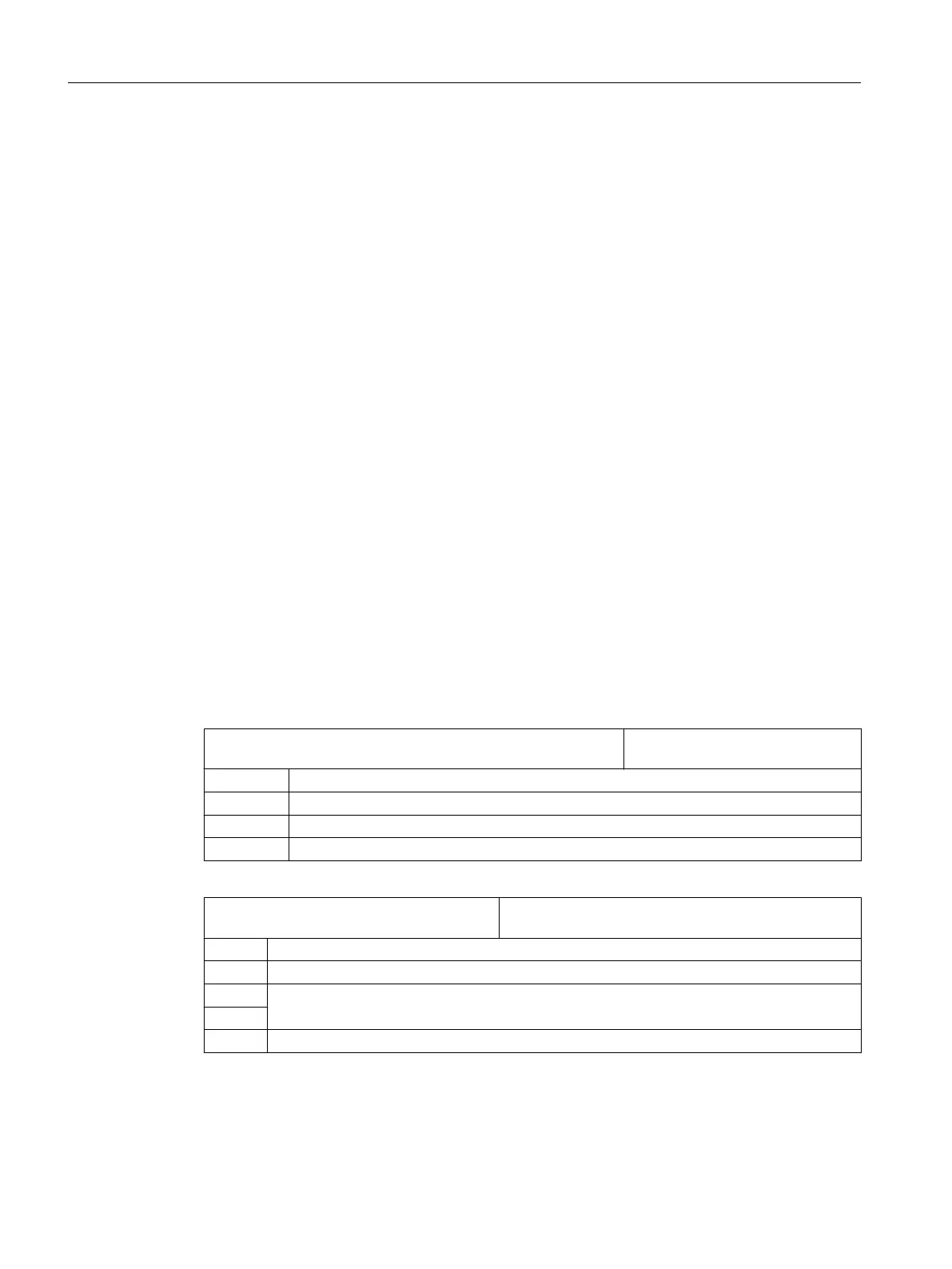

SD54782 $SNS_J_MEA_FUNCTION_MASK_TOOL Settings for the Tool measurement

in JOG input mask

Bit 2 Activates the "Enable automatic tool measuring" function.

Bit 3 Selects the tool probe calibration data field, enable.

Bit 10 Selects the individual cutting edge measurement

Bit 11 Selects spindle reversal when calibrating in the plane

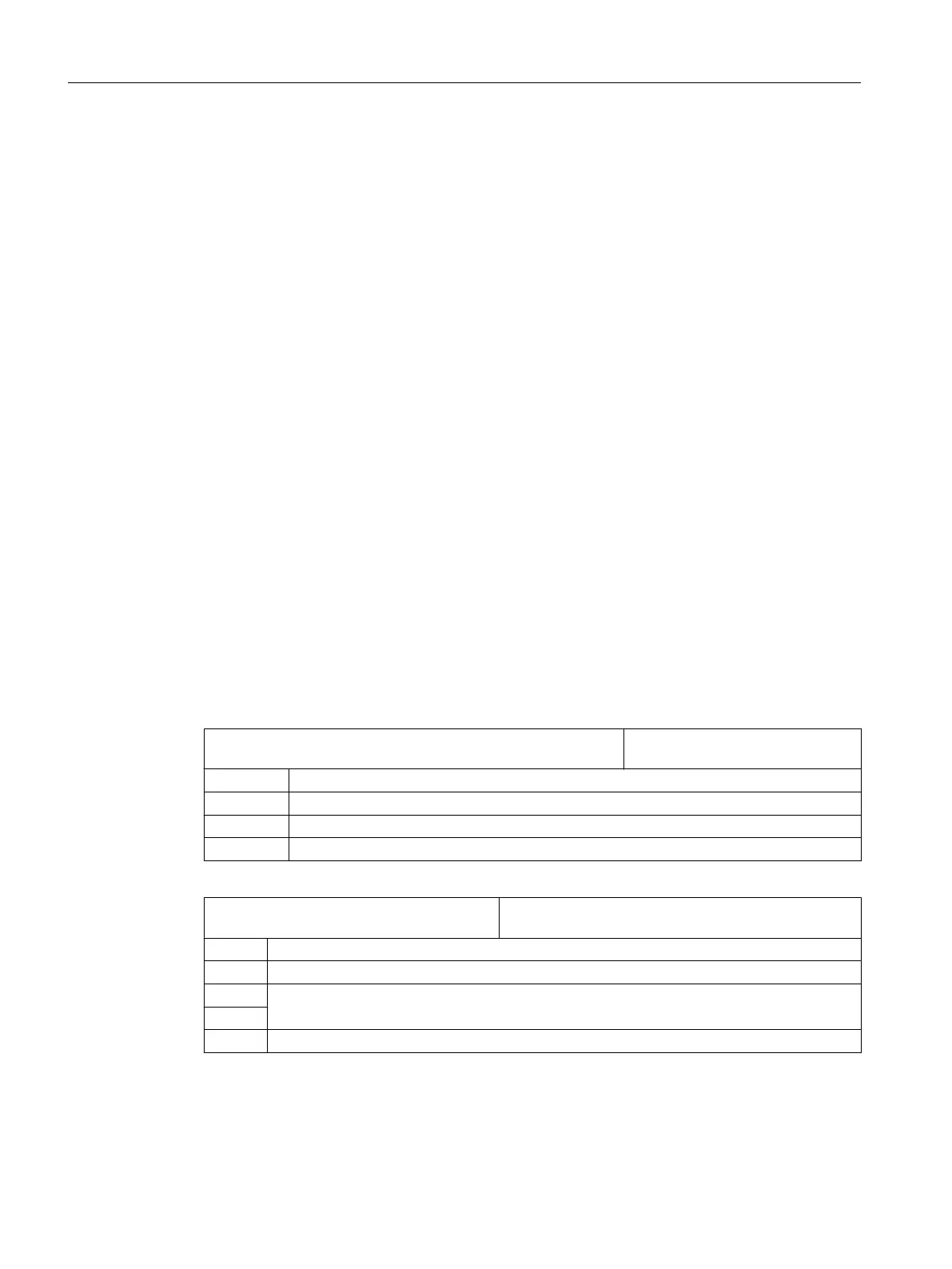

MD51784 $MNS_J_MEA_T_PROBE_APPR

_AX_DIR [i]

Measuring in JOG: Approach direction in the plane to

the tool probe

-2 Negative direction, 2nd measuring axis

-1 Negative direction, 1st measuring axis (default setting)

0

Positive direction, 1st measuring axis

1

2 Positive direction, 2nd measuring axis

Configuring cycles

7.9 Measuring cycles and measurement functions

SINUMERIK Operate

176 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...