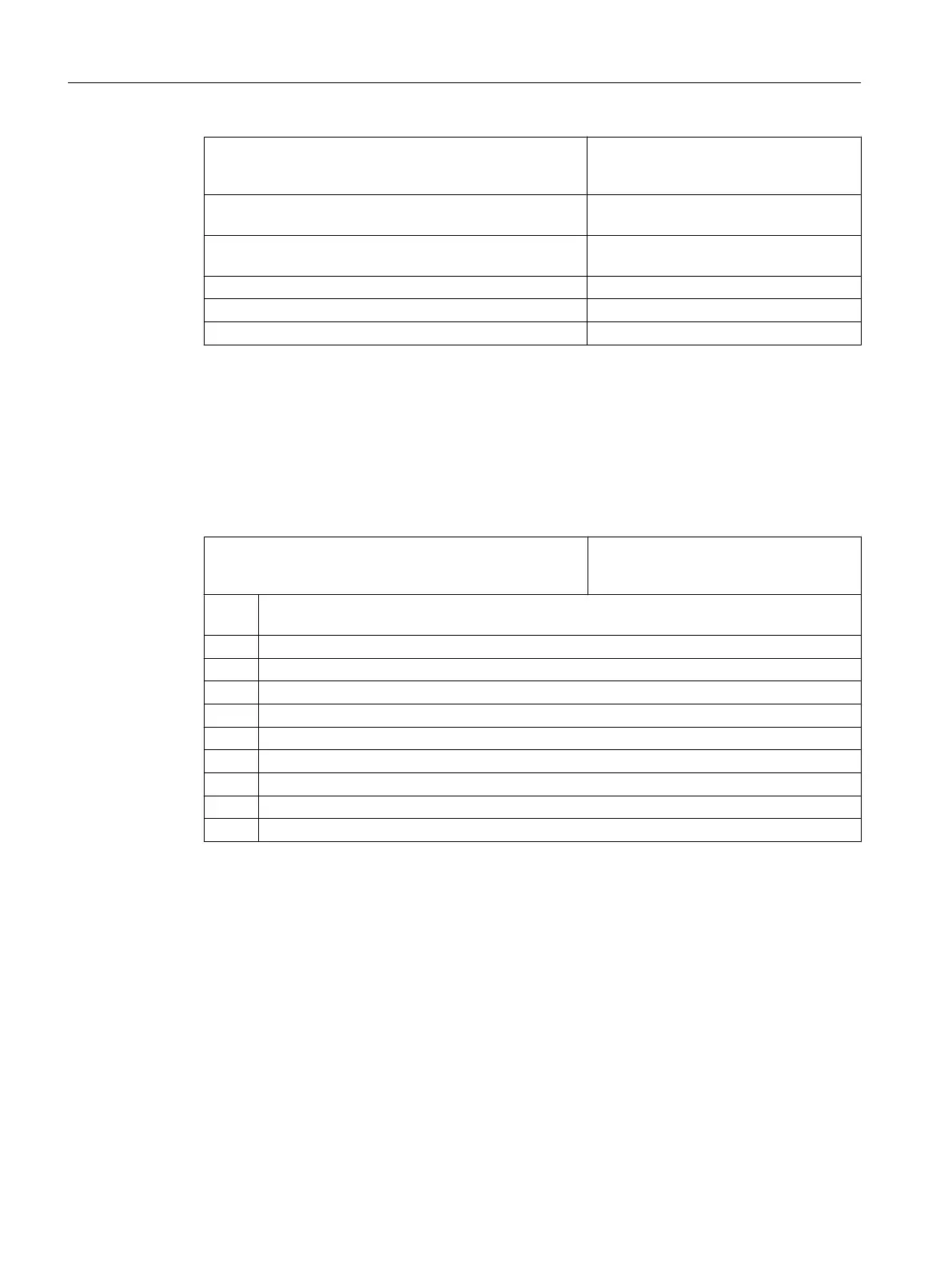

SD54606 $SNS_MEA_WP_TRIG_PLUS_DIR_AX3[n] Trigger point, plus direction,

3rd measuring axis opposite to the tool

direction. In the default case = 0.

SD54607 $SNS_MEA_WP_POS_DEV_AX1[n] Position deviation,

1st measuring axis in the plane.

SD54608 $SNS_MEA_WP_POS_DEV_AX2[n] Position deviation,

2nd measuring axis in the plane.

SD54609 $SNS_MEA_WP_STATUS_RT Calibration status of the axis positions

SD54610 $SNS_MEA_WP_STATUS_GEN[n] Calibration status

SD54611 $SNS_MEA_WP_FEED[n] Measuring feedrate when calibrating

7.9.4.3 Measuring tools at the milling machines

Settings

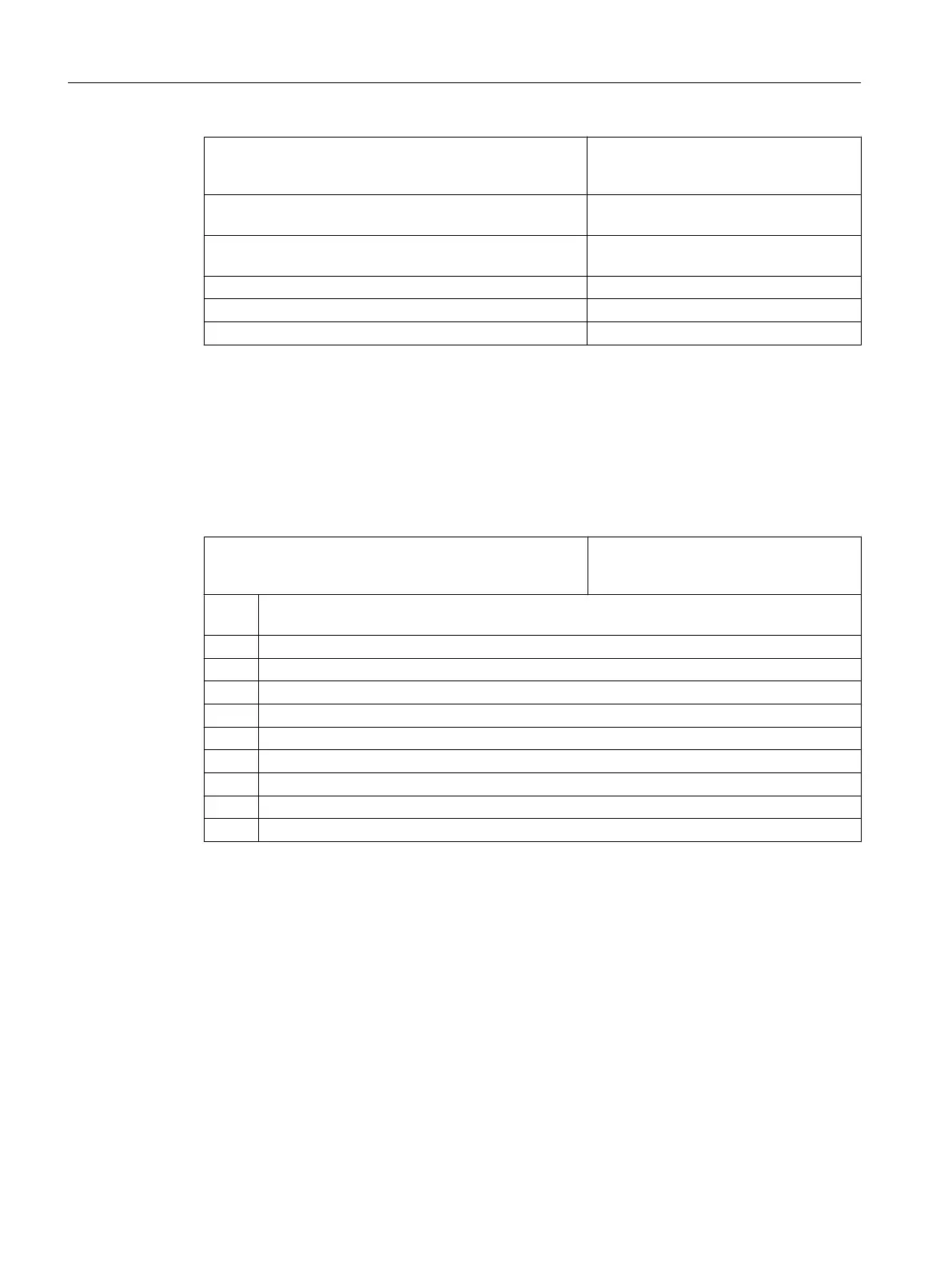

SD54762 $SNS_MEA_FUNCTION_MASK_TOOL Setting for the input screen, measuring

cycles in the automatic mode, tool meas‐

urement

Bit 3 Setting for the input screen, measuring cycles in the automatic mode, tool measurement,

enable tool probe calibration data field to be selected

Bit 4 Select calibration input measuring feed (VMS)

1)

Bit 5 Select input feedrate and spindle speeds when probing

Bit 7 Select measurement in MCS and WCS

Bit 8 Select measurement, absolute and incremental

Bit 9 Select tool offset, geometry and wear

Bit 10 Select individual cutting edge measurement

Bit 11 Selects spindle reversal when calibrating in the plane

Bit 12 Select number of measurements (_NMSP)

Bit 13 Select experience values (_EVNUM)

1)

Input, measurement feedrate is valid for AUTOMATIC and JOG

Calibration data of the tool probe, referred to the machine coordinate system

Before calibration is started, the position of the tool probe in the machine coordinate system

(MCS) must be entered

into the following general cycle setting data. In this case, the reference

point is the outer diameter or the tool length of the active tool in the spindle. If there is no tool

in the spindle, the reference points are the spindle center point and the tool reference point at

the spindle.

Configuring cycles

7.9 Measuring cycles and measurement functions

SINUMERIK Operate

192 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...