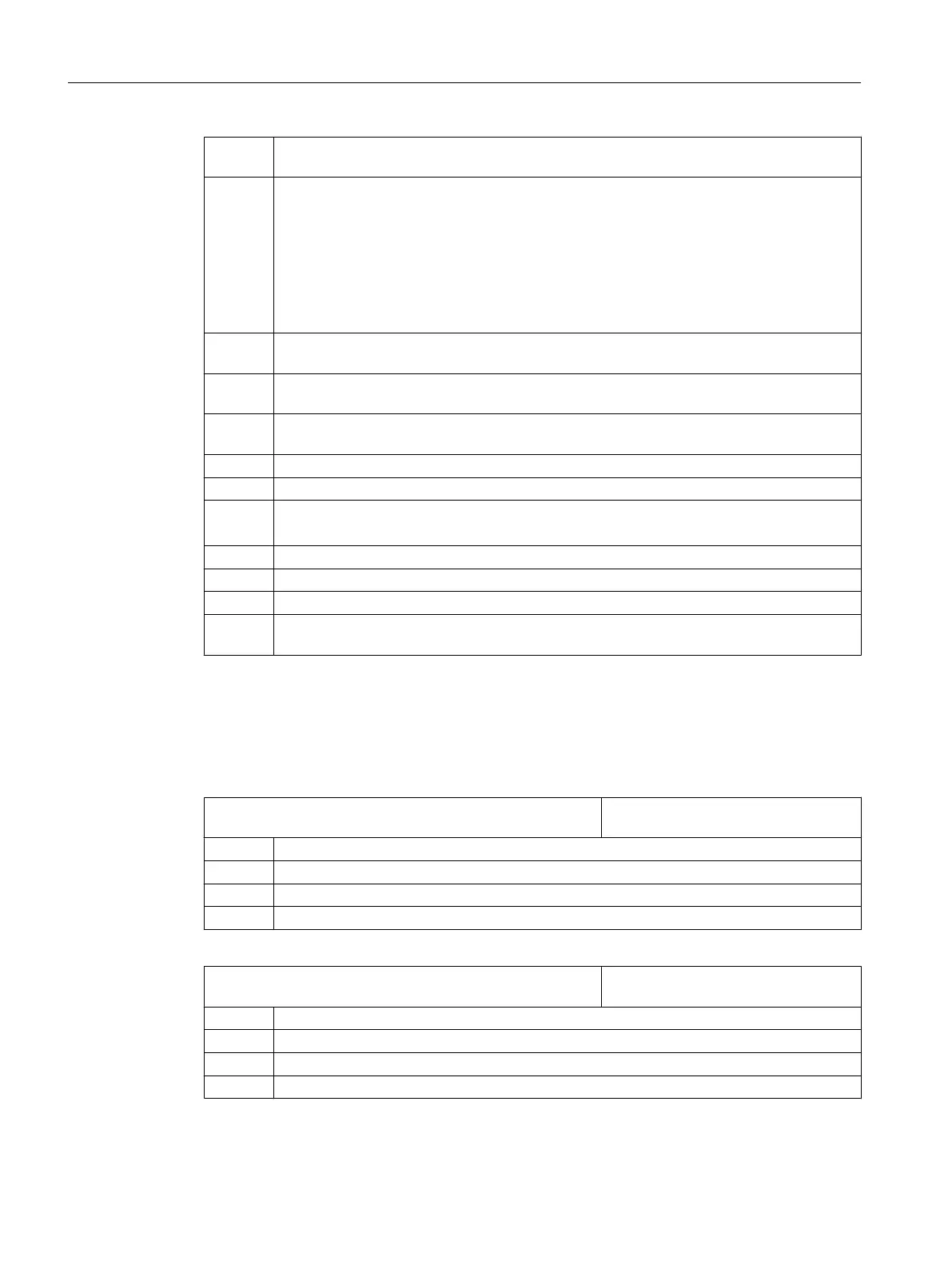

Bit 2 Boring CYCLE86: When positioning the spindle, take into account swiveled table kinematics

(tool carrier)

= 0 When positioning the spindle, do not take into account the components of the swiveled table

kinematics (swiveling with CYCLE800, tool carrier).

Note:

Only the rotary axis of the machine kinematics that rotates the workpiece is taken into ac‐

count. In the initial

state of the kinematics, this rotary axis must be orientated parallel to the

tool axis.

e.g. rotary axis C rotation around Z (for G17) rotary axis vector of the swivel data set V2xyz

= 0 , 0 , -1.

= 1 When positioning the spindle, take into account the components of the swiveled table kine‐

matics (swiveling with CYCLE800, tool carrier).

Bit 3 Tapping CYCLE84: Monitoring of the machine data MD31050 $MA_DRIVE_AX_RATIO_DE‐

NOM and MD31060 $MA_DRIVE_AX_RATIO_NUMERA of the spindle

Bit 4 Tapping CYCLE84, set monitoring of the machine data MD31050 $MA_DRIVE_AX_RA‐

TIO_DENOM and MD31060 $MA_DRIVE_AX_RATIO_NUMERA of the spindle

= 0 No monitoring

= 1 Monitoring

Bit 6 Boring CYCLE86: Adapt the spindle position to the tool orientation

Tool orientation can be realized using TOOLCARR or TRAORI before the cycle is called.

= 1 Bits 1 and 2 are no longer effective.

Bit 7 Boring CYCLE86: Adapt the direction of retraction travel in the plane to the active mirroring

= 0 Retraction in the plane is realized as programmed.

= 1 When mirroring is active, the direction when retracting in the plane is adapted in the cycle

to the active mirroring.

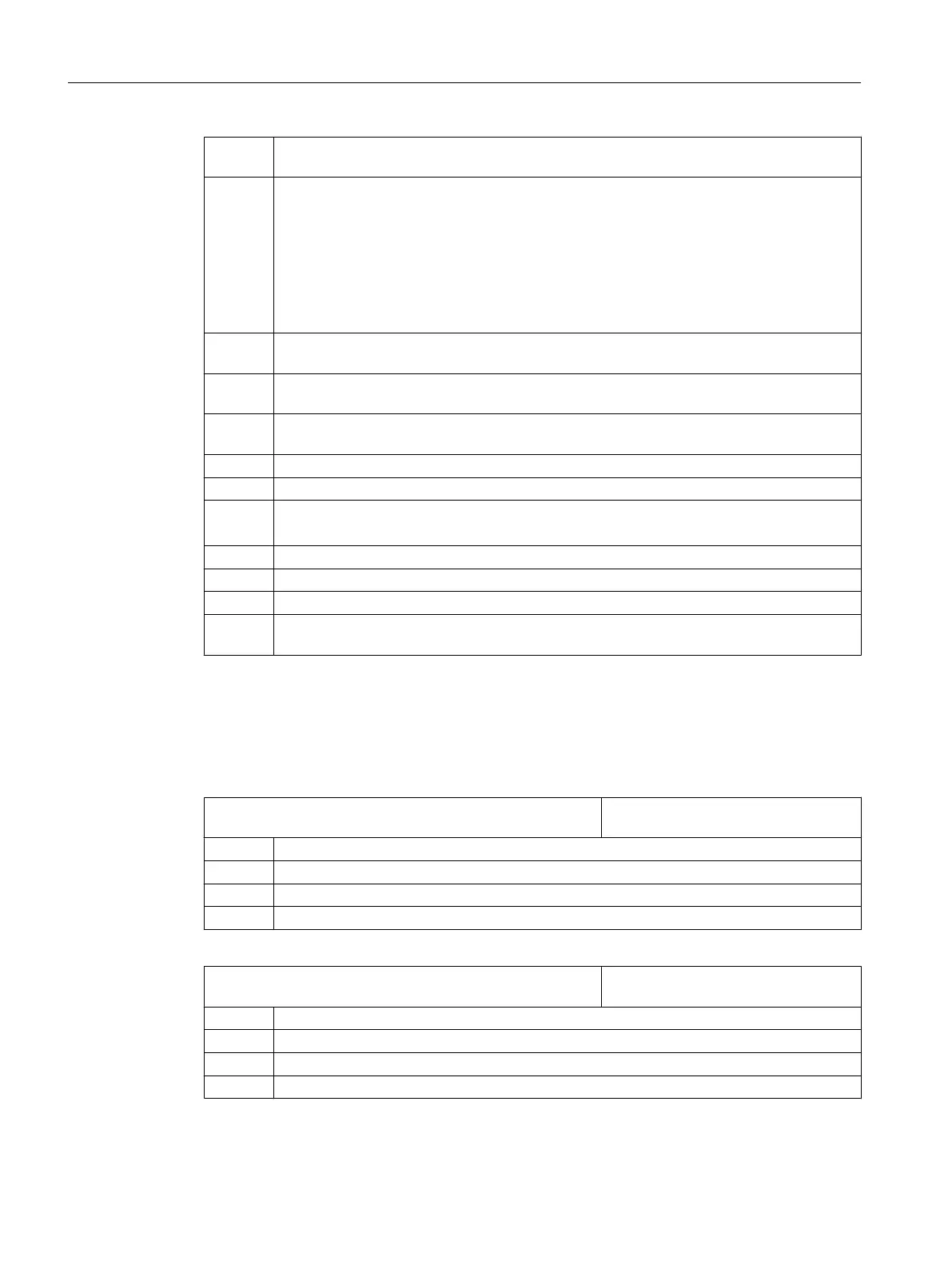

Tapping (CYCLE84 and CYCLE840)

If the technology screens are hidden using the channel-specific configuration machine data

MD52216 $MCS_FUNCTION_MASK_DRILL, then the settings in the following channel-

specific cycle setting data are effective:

SD55481 $SCS_DRILL_TAPPING_SET_GG12[0] Setting tapping G group 12:

Block change behavior for exact stop

= 0 Exact stop response as before the cycle call (default value).

= 1 G601

= 2 G602

= 3 G603

SD55482 $SCS_DRILL_TAPPING_SET_GG21[0] Setting tapping G group 21:

Acceleration behavior

= 0 Acceleration behavior as before the cycle call (default value).

= 1 SOFT

= 2 BRISK

= 3 DRIVE

Configuring cycles

7.2 Technology cycles for drilling

SINUMERIK Operate

80 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...