Between traveling to the fixed stop and gripping, the counterspindle can retract a short distance

to counteract compressive stress in the workpiece.

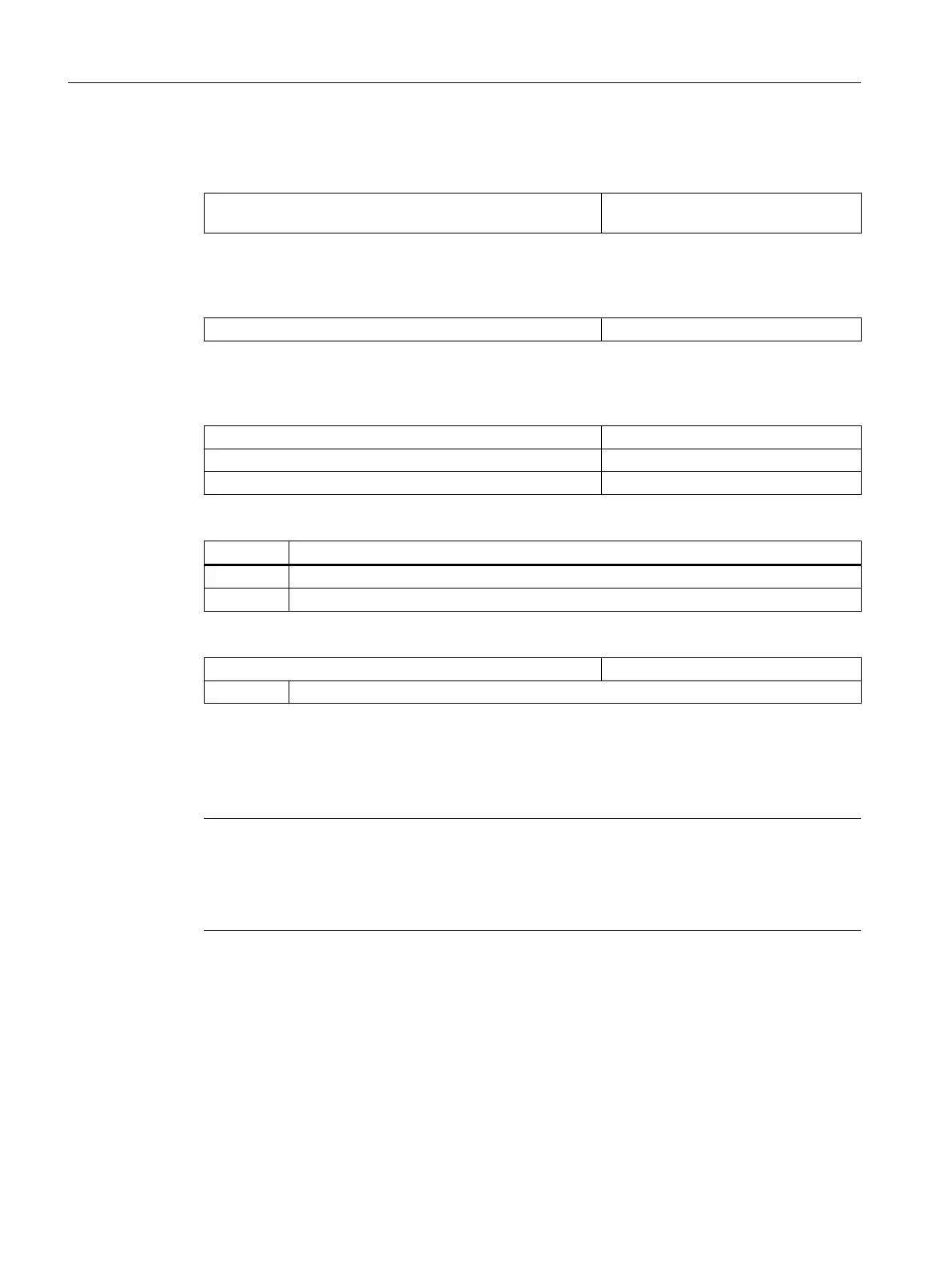

SD55553 $SCS_TURN_FIXED_STOP_RETRACTION Retraction distance before clamping af‐

ter fixed stop.

After gripping you can cut off the workpiece. Before doing so, the counterspindle can retract

a short distance with the workpiece to exert tensile stress on the workpiece. This relieves

pressure on the tool when cutting off.

SD55543 $SCS_TURN_PART_OFF_RETRACTION Retraction distance before cut-off.

After parting, you can carry out a cut-off check and for turning, use the "Travel to fixed stop"

function. You can activate/deactivate the cut-off check using the channel-specific cycle setting

data:

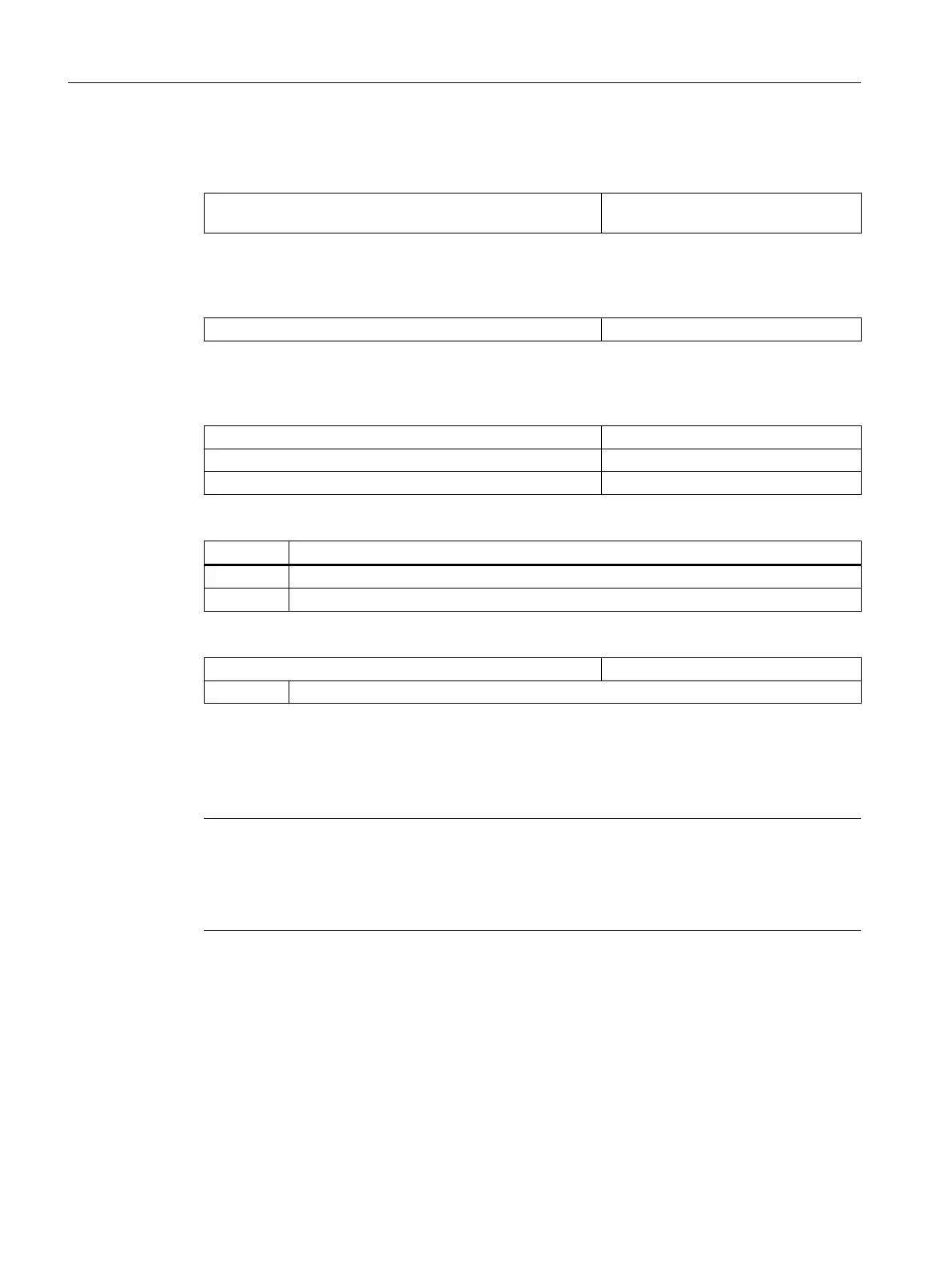

SD55540 $SCS_TURN_PART_OFF_CTRL_DIST Distance for cut-off check.

SD55541 $SCS_TURN_PART_OFF_CTRL_FEED Feedrate for cut-off check.

SD55542 $SCS_TURN_PART_OFF_CTRL_FORCE Force for cut-off check in %.

The cut-off is successful when travel to fixed stop fails. The following alarms are output:

Alarm Alarm text

20091 Axis %1 has not reached the fixed stop.

20094 Axis %1 end stop has been aborted.

You can switch off the alarm display using the following machine data:

MD37050 $MA_FIXED_STOP_ALARM_MASK Enabling the fixed stop alarms.

= 2 Suppressing alarms 20091 and 20094.

You can set this machine data axis-specifically in the "Machine Data" window in the "Tool zero"

operating area.

If, however, the specified force is reached during the cut-off check (i.e. travel to fixed stop is

successful), alarm 61255 "Error during cut-off: Tool break?" is issued.

Note

The

"Travel

to

fixed

stop" function can also be used when gripping the spindle (see above). If

travel to fixed stop does not succeed when gripping, an alarm will of course also be issued.

Instead of alarms 20091 and 20094, the alarm 61254 "Error during travel to fixed stop" will be

issued.

Machine manufacturer cycle

If you perform one of the following actions, you must adapt the machine manufacturer cycle

CUST_TECHCYC.SPF.

● Switch between spindle and C axis mode for the main spindle or counterspindle.

● Open, close, flush chuck (main spindle / counterspindle).

● Change default settings for the coupling of the main spindle and counterspindle.

Configuring cycles

7.5 Turning

SINUMERIK Operate

114 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...