5.2 b: Application

168 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

I Control

The output of I control is the integral of the deviation. It minimizes the offset between target and feedback value that

typically remains when pure P control is used. The integral time (I time) constant determines how fast the offset is

eliminated.

D Control

D control predicts the deviation signal by multiplying its derivative (slope of the deviation) with a time constant, then

adds this value to the PID input. This way the D portion of a PID controller provides a braking action to the controller

response and can reduce the tendency to oscillate and overshoot.

Be aware that D control tends to amplify noise on

the deviation signal, which can result in control instability. D control

should therefore only be used when necessary.

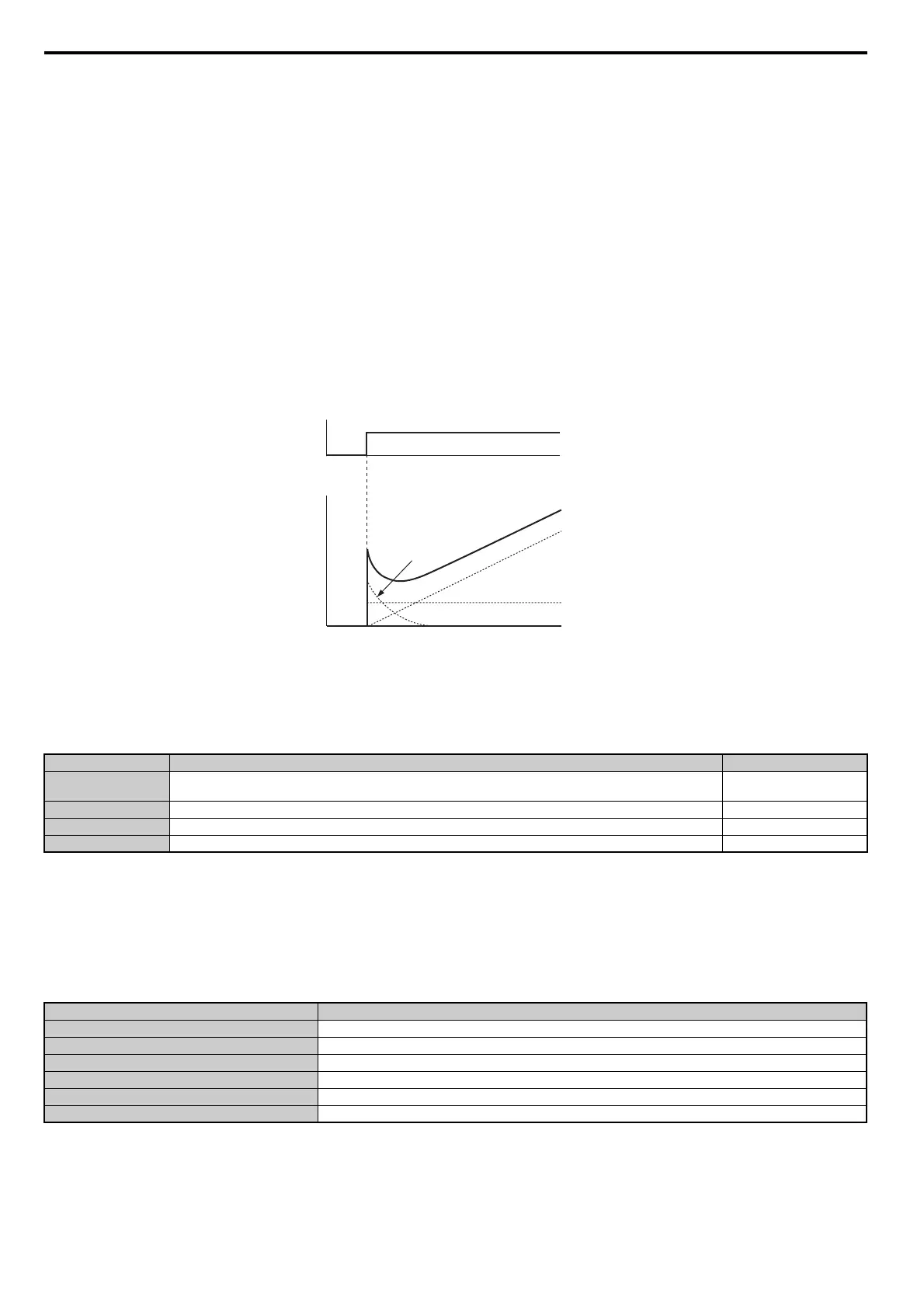

PID Operation

To better demonstrate how PID works, Figure 5.25 shows how the PID output changes when the PID input (deviation)

jumps from 0 to a constant level.

Figure 5.25

Figure 5.25 PID Operation

Using PID Control

Applications for PID control are listed in Table 5.8.

Table 5.8 Using PID Control

PID Setpoint Input Methods

The PID setpoint input can be input from one of the sources listed in Table 5.9.

If none of the sources listed in Table 5.9 are used, the frequency reference source in b1

-01 (or b1-15) or one of the inputs

listed in Table 5.9 becomes the PID setpoint.

Table 5.9 PID Setpoint Sources

Note: A duplicate allocation of the PID setpoint input will cause an oPE07 (Multi-Function Analog Input Selection Error) alarm.

Application Description Sensors Used

Speed Control

Machinery speed is fed back and adjusted to meet the target value. Synchronous control is performed using speed data from

other machinery as the target value

Tachometer

Pressure Maintains constant pressure using pressure feedback. Pressure sensor

Fluid Control Keeps flow at a constant level by feeding back flow data. Flow rate sensor

Temperature Control Maintains a constant temperature by controlling a fan with a thermostat. Thermocoupler, Thermistor

PID Setpoint Source Settings

Analog Input A1 Set H3-02 = C

Analog Input A2 Set H3-10 = C

Analog Input A3 Set H3-06 = C

MEMOBUS/Modbus Register 0006H Set bit 1 in register 000FH to 1 and input the setpoint to register 0006H

Pulse Input RP Set H6-01 = 2

Parameter b5-19 Set parameter b5-18 = 1 and input the PID setpoint to b5-19

PID input

I control

PID Output

D control

Time

PID output

Time

P control

Loading...

Loading...