5.2 b: Application

YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual 169

PID Feedback Input Methods

Either one feedback signal can be input for normal PID control, or two feedback signals can be input for controlling a

differential process value.

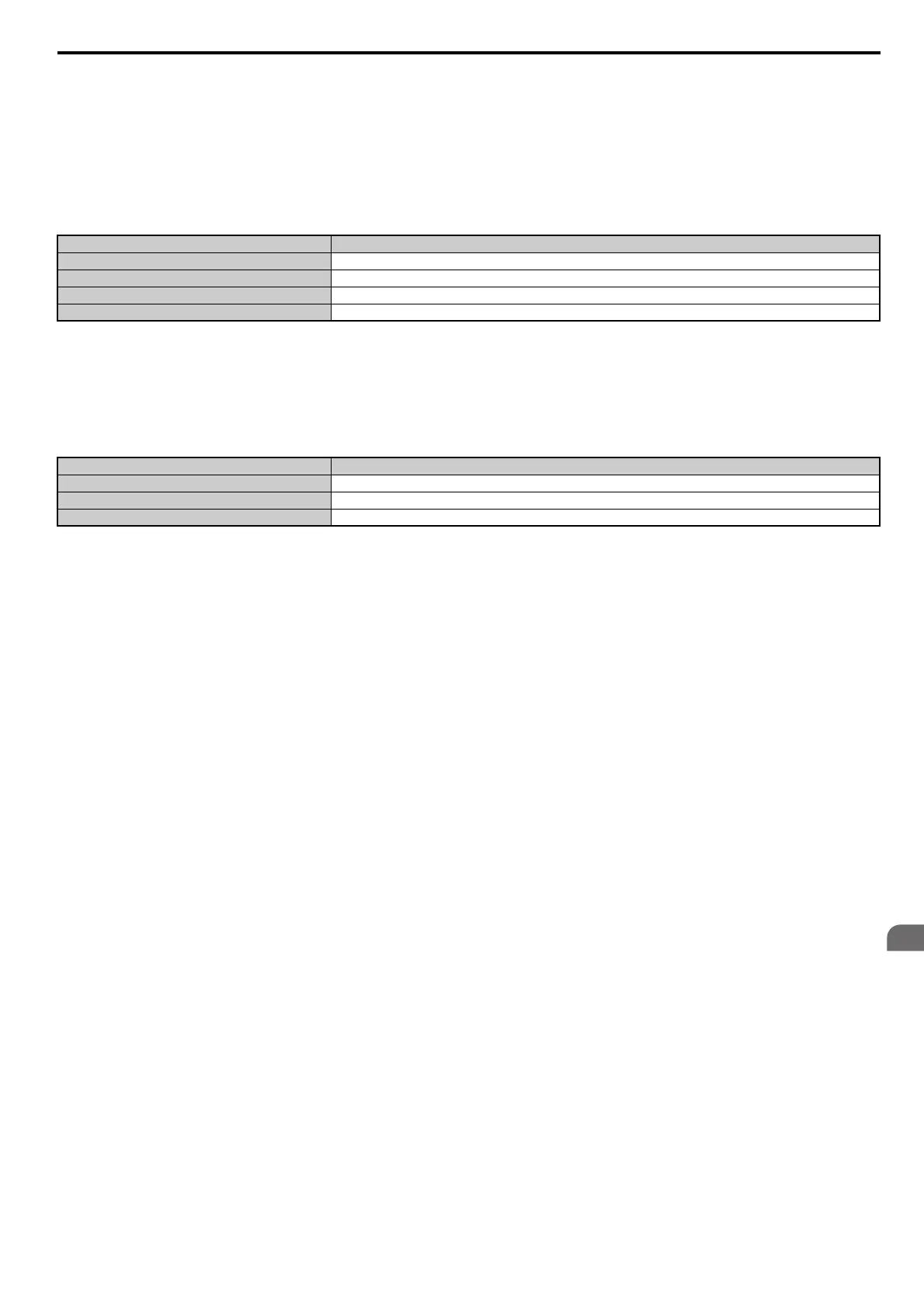

Normal PID Feedback

The PID feedback signal can be input from one of the sources listed in Table 5.10.

Table 5.10 PID Feedback Sources

Note: A duplicate allocation of the PID feedback input will cause an oPE07 (Multi-Function Analog Input Selection Error) alarm.

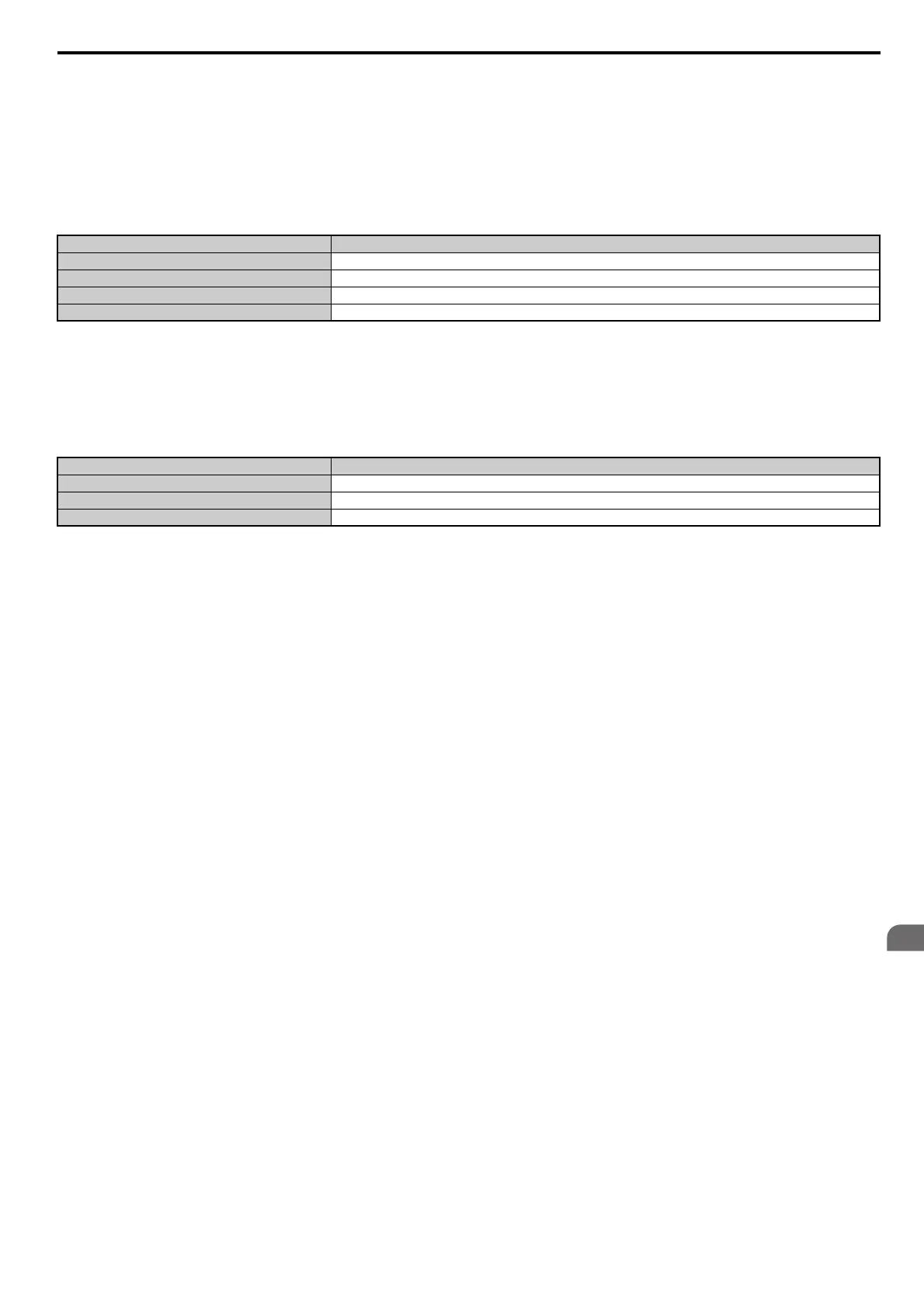

Differential Feedback

The second PID feedback signal for differential feedback can come from the sources listed in Table 5.11. The differential

feedback function is automatically enabled

when a differential feedback input is assigned.

Table 5.11 PID Differential Feedback Sources

Note: A duplicate allocation of the PID differential feedback input will cause an oPE07 (Multi-Function Analog Input Selection Error)

alarm.

PID Feedback Source Settings

Analog Input A1 Set H3-02 = B

Analog Input A2 Set H3-10 = B

Analog Input A3 Set H3-06 = B

Pulse Input RP Set H6-01 = 1

PID Differential Feedback Source Settings

Analog Input A1 Set H3-02 = 16 (Differential PID Feedback)

Analog Input A2 Set H3-10 = 16 (Differential PID Feedback)

Analog Input A3 Set H3-06 = 16 (Differential PID Feedback)

Loading...

Loading...