Setting Up Your Test

The basic test set-up required for making frequency response measurements

depends upon the type of structure to be tested and the level of results desired.

Other factors, including the support fixture and excitation method, affect the

amount of hardware needed to perform the test. For making measurements on

simple structures, the exciter mechanism can be as basic as an instrumented

hammer and requires a minimum amount of hardware. An electrodynamic

shaker may be needed to excite a more complicated structure.

The first step in setting up a structure for frequency response measurements is

to consider the fixturing mechanisms. This is a key step in the process as it

affects the overall structural characteristics. The selection of a fixture goes

beyond the scope of this book. Several texts are available that focus on test

fixtures. They include:

• Vibration and Shock Test Fixture Design by Wayne Tustin and Robert Mercado

(Tustin Technological Institute, 1984).

• L.D.MitchellandK.B.Elliott,“HowToDesignStingersforVibrationTestingof

Structures,” Sound and Vibration, April 1984.

• Modal Testing: Theory and Practice by Dave J. Ewins (Wiley Interscience, 1984).

The next step in the measurement process involves selecting an excitation

function along with an excitation mechanism. The choice of the excitation

function dictates the choice of the excitation mechanism. The choice depends

on several factors:

• available signal processing equipment

• characteristics of the structure

• general measurement considerations

• the excitation mechanism.

The shaker test and the impact test are the most common excitation

mechanisms.

Once an excitation mechanism has been setup to force the structure into

motion, you need to select the transducers which sense the force and motion.

The piezoelectric transducer is widely used. It is an electromechanical sensor

which generates an electrical output when subjected to vibration.

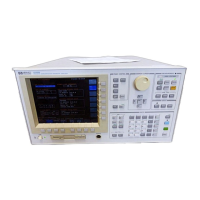

Agilent 35670A

Operator's Guide Measuring Structures

2-3

Loading...

Loading...