To measure a step response

The primary objective in designing a control system is to construct a system that

achieves the desired output level as fast as possible and maintains that output with

little or no variation or steady state error. The step response is a technique that

measures a control system’s compliance with the design goals. This task utilizes a

step signal created with the Arbitrary Source, Option 1D4.

1 Create and store a step signal in data register D1.

See “To create a step signal” in chapter 6.

2 Initialize the analyzer.

Press [

Preset

][

DO PRESET

].

Press [

Inst Mode

][

HISTOGRAM/TIME

].

Press [

Meas Data

].

Press [

CHANNEL 1 2 3 4

] to highlight 2.

Press [

UNFILTERD TIME CH2

].

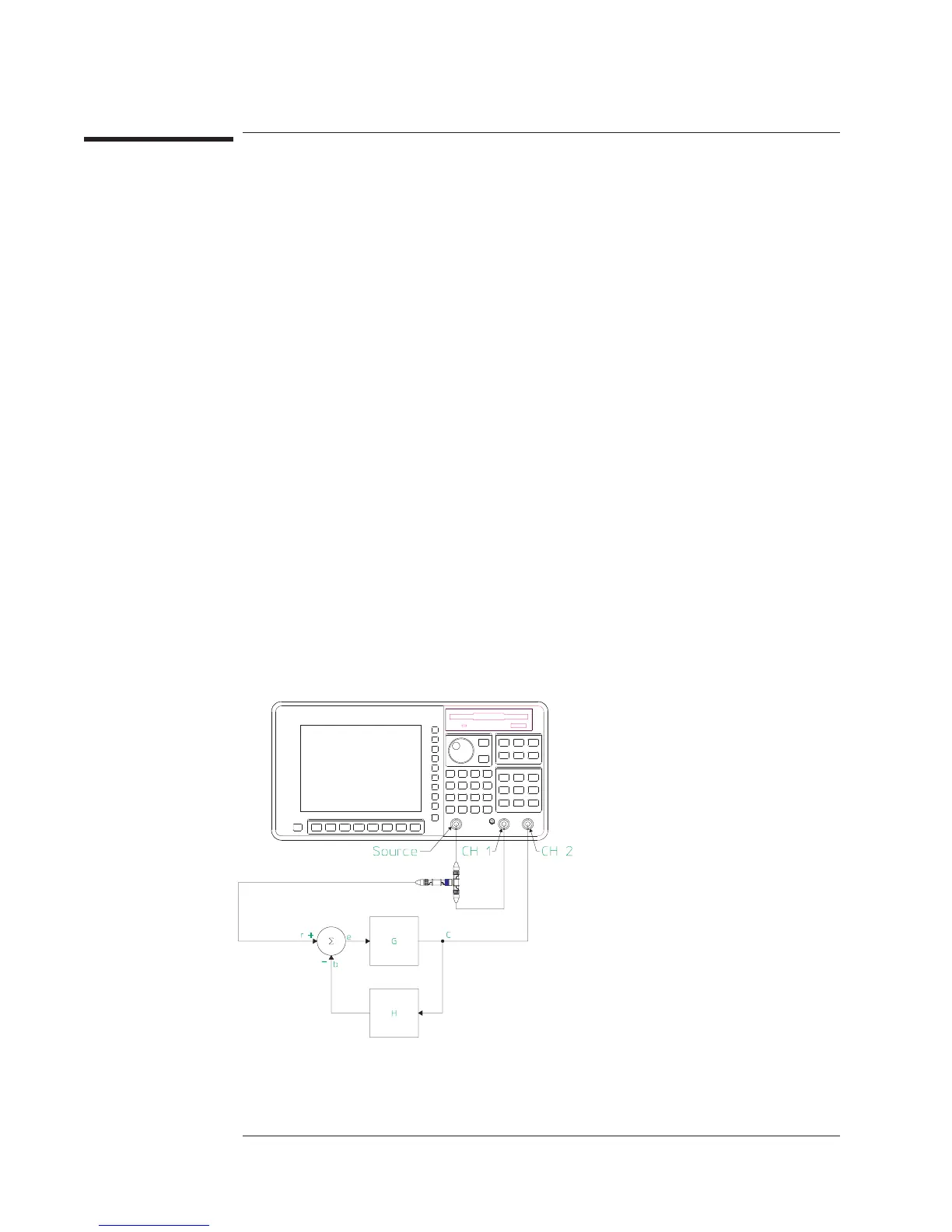

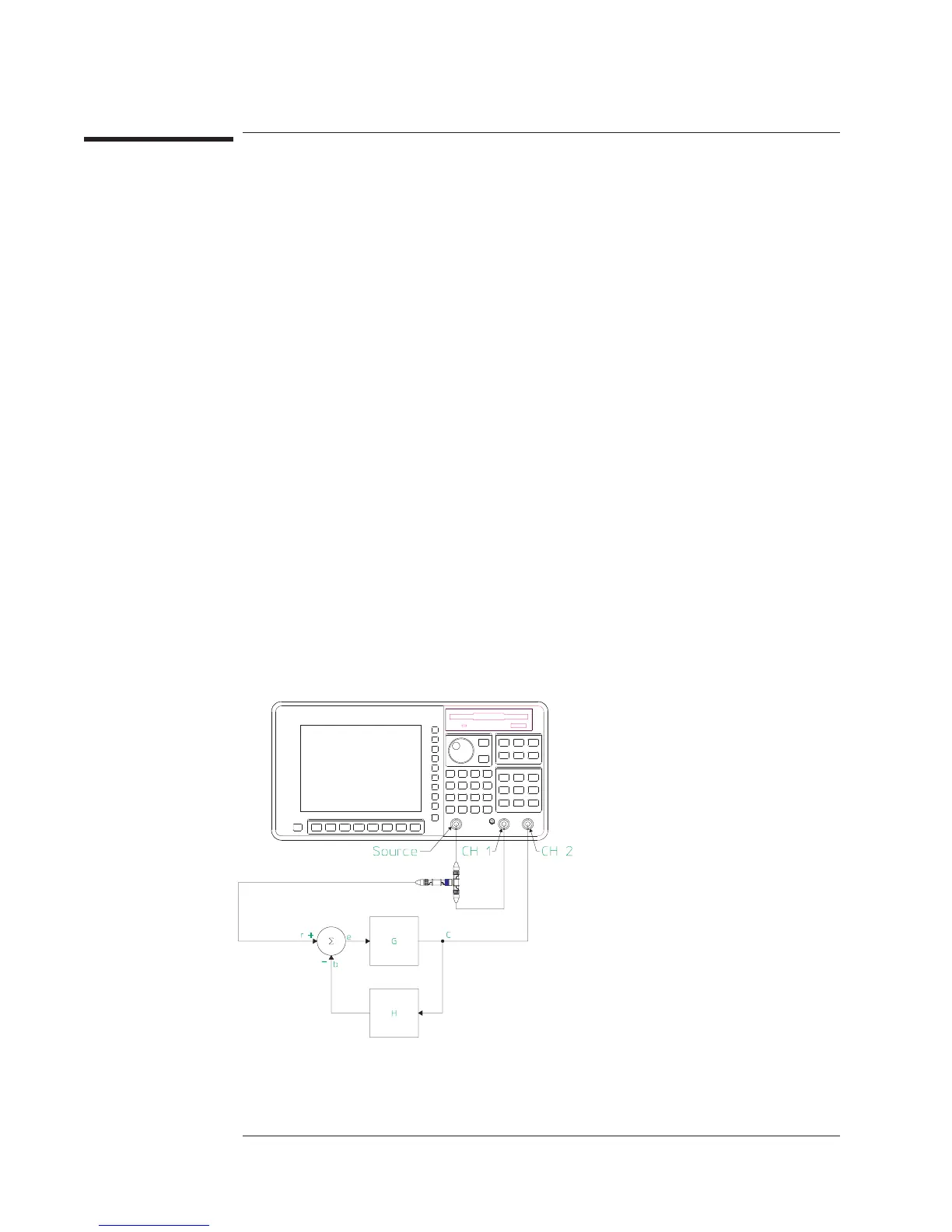

3 Connect the device-under-test (DUT) as shown in the illustration below.

4 Specify the measurement parameters.

Press [

Freq

][

RECORD TIME

] <number> <unit>.

Press [

Input

][

CH1 FIXED RANGE

] <number> <unit>.

Press [

Source

][

MORE CHOICES

][

ARBITRARY (D1 - D8)

].

Press [

Rtn

].

Press [

LEVEL

] <number> <unit>.

Press [

SOURCE ON OFF

] to highlight ON.

Agilent 35670A

Measuring Control Systems Operator's Guide

5-8

Loading...

Loading...