100-412-234 REV. 06 87

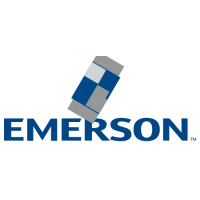

5.8.1 For a 20 kHz System

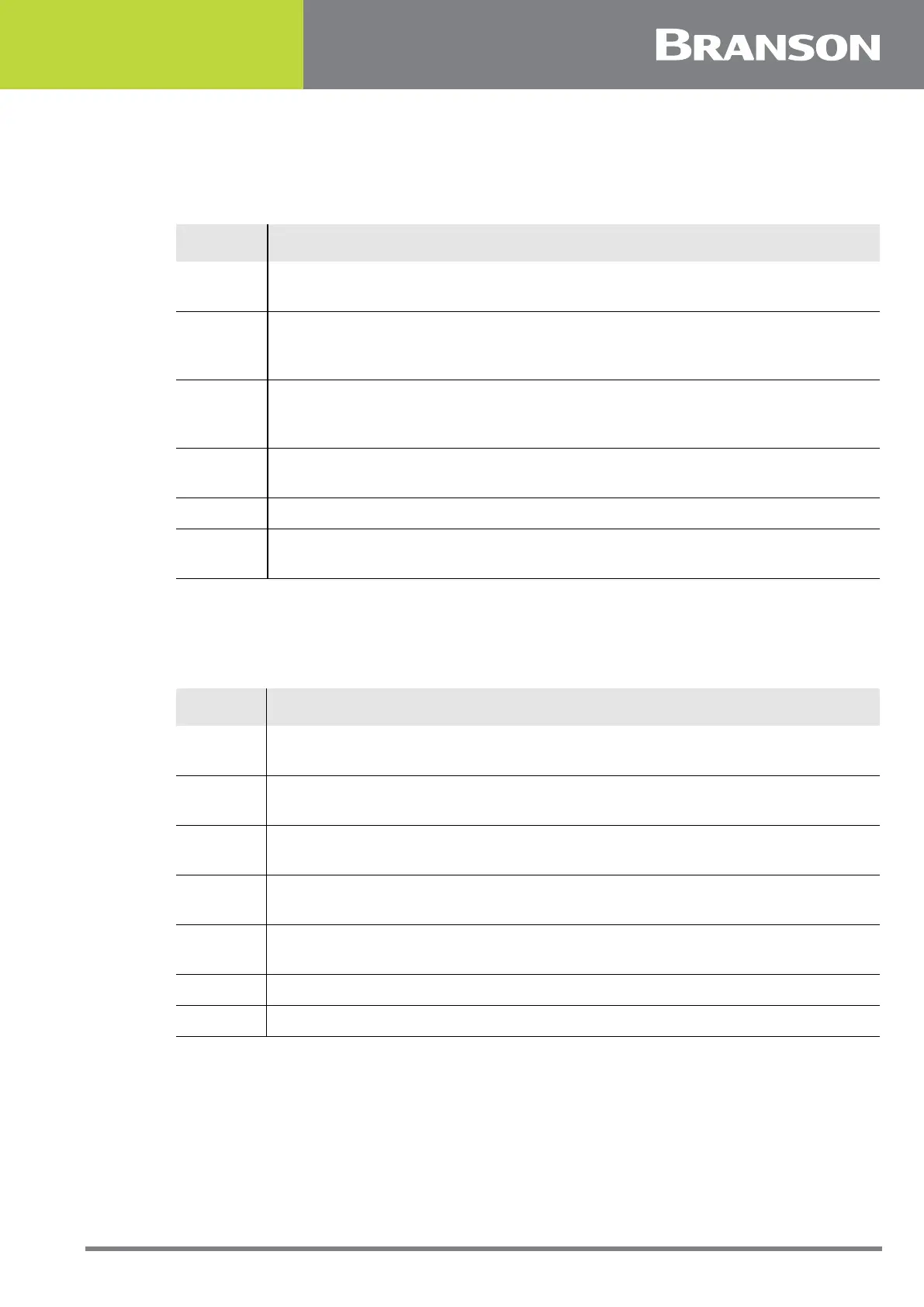

5.8.2 For a 30 kHz System

*Loctite is a registered trademark of Henkel Corporation, U.S.A.

Table 5.10 For a 20 kHz System

Step Action

1

Clean the mating surfaces of the converter, booster, and horn. Remove any

foreign material from the threaded holes.

2

Install the threaded stud into the top of the booster. Torque to 450 in-lbs,

50.84 Nm. If the stud is dry, apply 1 or 2 drops of a light lubricating oil

before installing.

3

Install the threaded stud into the top of the horn.Torque to 450 in-lbs,

50.84 Nm. If the stud is dry, apply 1 or 2 drops of a light lubricating oil

before installing.

4

Install a single Mylar washer (matching the size of the washer to the stud)

to each interface.

5 Assemble the converter to the booster and the booster to the horn.

6

Torque to 220 in-lbs, 24.85 Nm. (Torque 20kHz Solid Mount Converter to

250 in-lbs, 28.25Nm.)

Table 5.11 For a 30 kHz System

Step Action

1

Clean the mating surfaces of the converter, booster, and horn. Remove any

foreign material from the threaded holes.

2

Apply a drop of Loctite®* 290 thread-locker (or equivalent) to the studs for

the booster and horn

3

Install the threaded stud into the top of the booster; torque to 290 in-lbs,

32.76Nm, and let cure for 30 minutes.

4

Install the threaded stud into the top of the horn; torque to 290 in-lbs,

32.76Nm, and let cure for 30 minutes

5

Install a single Mylar washer (matching the size of the washer to the stud)

to each interface.

6 Assemble the converter to the booster and the booster to the horn.

7 Torque to 185 in-lbs, 21Nm.

Loading...

Loading...