100-412-234 REV. 06 231

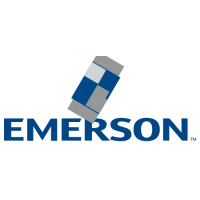

B.1.3 Failure of Alarms

Table B.2 Failure of Alarms and Messages, with Probable Cause and Corrective Action

Alarm

ID

Display

Message

Alarm Condition/

Cause

Corrective Action

601

Start Switch

Closed

Start switches are still

active after the

carriage is at ULS for 6

seconds.

Deactivate start switches.

604

Upper Limit

Switch

Upper Limit Switch

was not engaged at

the end of weld cycle.

The switch might have

failed or the electrical

wiring might be loose.

Verify the electrical

connections for the Upper Limit

Switch or replace the switch.

609

Start Switches

Lost

Checked after both

start switches, and

before trigger.There is

a 10 ms debounce

time before considered

lost.

Press start switches again.

620

Pretrigger

Timeout

Pretrigger has not

occurred within 10

seconds of carriage

leaving home (of

upper limit becoming

inactive).

Check the distance setting for

pretrigger to be sure the

carriage is traveling at least

that far.

Repair/replace Control Board.

623

Thermal

Overload

Thermal sensors on

the Power Supply

indicate that the

temperature is above

the maximum

operating

temperature.

Lower the duty cycle by

decreasing the on time or

increasing the off time. Ensure

fans are operational and

internal components are free of

dust.

624 Preset Data/BBR

Corrupted data in

preset. Checked at

power up.

Repair/replace the Control

Board.

Replace battery.

625

Horn Return

Timeout

The Horn did not

retract to the home

position after the weld

was completed and

within the correct

time. The Horn might

be jammed or air

pressure might have

failed. The Upper Limit

Switch might also have

failed.

Verify that air pressure is

correct. Check for obstructions

or jams that would prevent the

Horn from returning. Verify the

operation of the Upper Limit

Switch.

Loading...

Loading...