100-412-234 REV. 06 165

6.15 Horn Down

Use Horn Down to verify that your fixture is properly set up or to determine the absolute

distance that the horn needs to travel to weld your parts. After pressing the Horn Down

button you can press the start switches, or you can use manual override to bring the horn

down to the position you have set without ultrasonic energy on by using the mechanical

stop. Once the horn is in position, you can release the start switches in order to verify

your setup.

Each time you enter the Horn Down menu, the weld force and downspeed settings are

transferred from the weld setup.

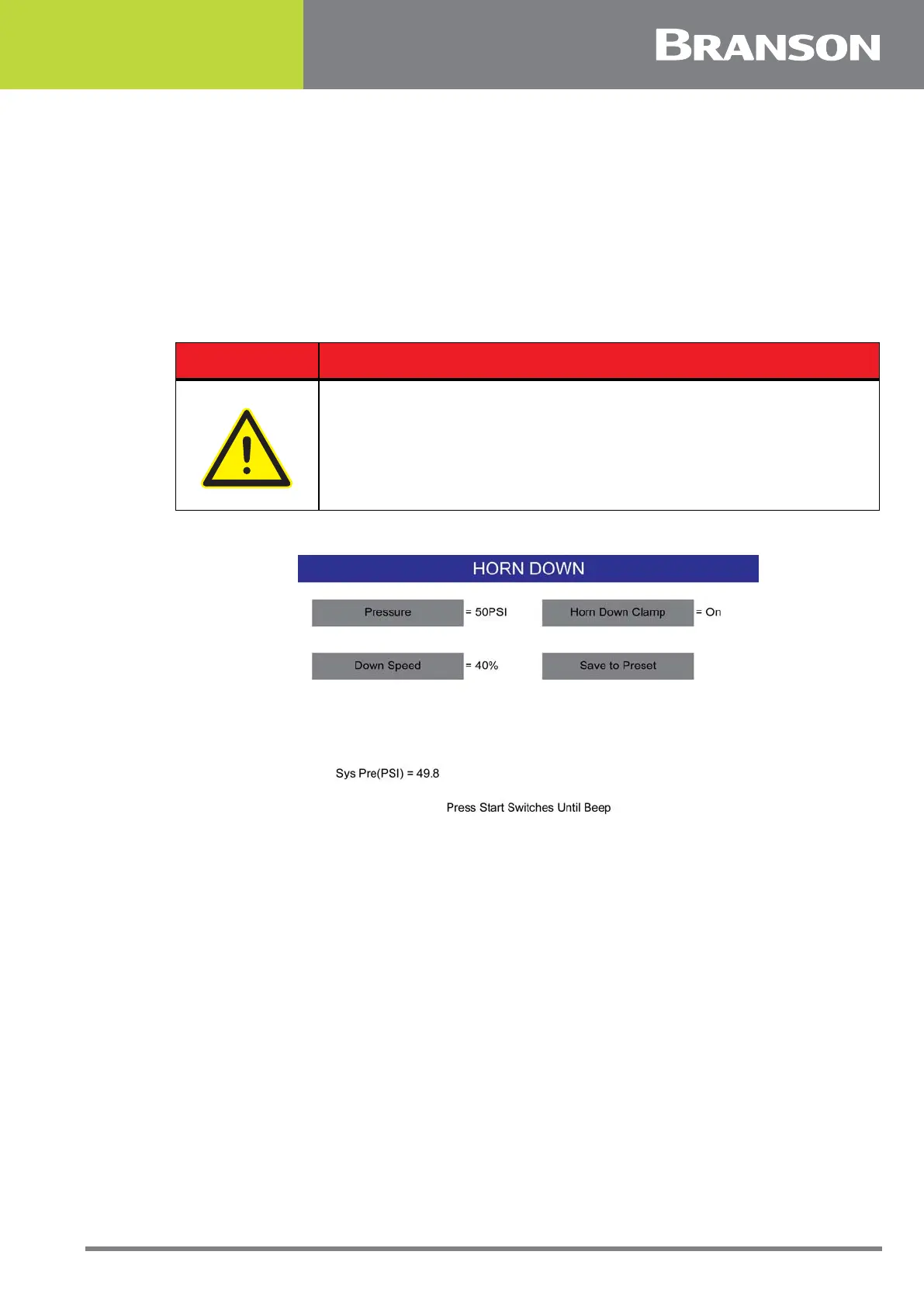

Figure 6.55 Horn Down

Turning the Horn Down Clamp On will cause the horn to remain at the workpiece when the

Start Switches are released, until it is released by pressing the Weld Results Button.

Pressing Retract will bring the horn up, and you will remain in the Horn Down screen.

With Horn Down Clamp Off, the horn will only stay down as long as the start switches are

held on.

Pressure and downspeed can also be changed from this menu.

Press the Save to Preset button to copy the horn down pressure and downspeed to the

current preset.

DANGER

Make sure all hands are clear of the horn and base surface.

Loading...

Loading...