When cutting most materials using the Zing blade holder, setting the perfect height for many thin materials is

not a concern. Put the blade holder into the Zing and rest the outer ridge of the blade holder on the rim of

the blade holder seat. Tighten the screw. This will provide a good height for cutting paper and vinyl.

It is only in the cutting of thicker materials, such as cardstock, chipboard, craft foam, craft plastic, stiffened

felt, etc, that the blade tip height will need to be set higher. There are two reasons for doing this:

You do not want the blade tip to be dragging across the material when moving to the point to begin the

cut.

The dropping of the blade will invoke more downward force. This can make a big difference when

cutting thicker denser materials, such as chipboard and craft plastic, which need the blade tip a little

higher, but not too high:

One recommended method for getting the same height set for all of your cuts is to use three old credit

cards. Set the three cards in a stack on top of the material you plan to cut. With the Zing turned off you can

move the blade carriage to the left until it is over the cards. Loosen the front screw and insert the blade

holder so that the tip of the blade is touching the top card. Now tighten the front screw and remove the

cards. This distance will provide the blade some “punch room” to give the extra force and more consistent

cutting of your material. You can also use a stack of 25 Post-It note sheets or even a stack of 12 squares

cut from Georgia Pacific 100# cardstock. Label these and keep next to your Zing!

Adjust the Speed, Force, and Number of Passes Based on the Material and Shapes

Using correct cut settings is equally important as the type of blade, blade length, and blade height. Refer to

Sections 2.03 - 2.05 for details. Again, some suggested settings are located at the end of this chapter and

settings for using the various Zing accessory tools are located at the end of Chapter 10.

Perform Test Cuts!

Use the test function in MTC to make test cuts. Do not proceed with your cut until the test cut is clean. When

cutting intricate shapes, a test cut of an intricate image, such as a letter or a small portion of your rhinestone

pattern, might be a better indicator of correct settings. Refer to Section 2.09.

Know Where Your Images Will Cut

Practice with the test pen until you know, with 100% confidence, where your images will be drawn. This is

important since you do not want to be guessing when you begin actually cutting with a blade. Refer to

Section 2.07 for details and videos on the options for controlling the locations of your cuts.

Adjust Blade Offset If Needed

What is the blade offset? It is the horizontal distance from the center of the blade shaft to the tip of the

blade. A pen or engraving tool has an offset of 0 because the tip is centered with the center of the

pen/engraving tool shaft. But a blade is different:

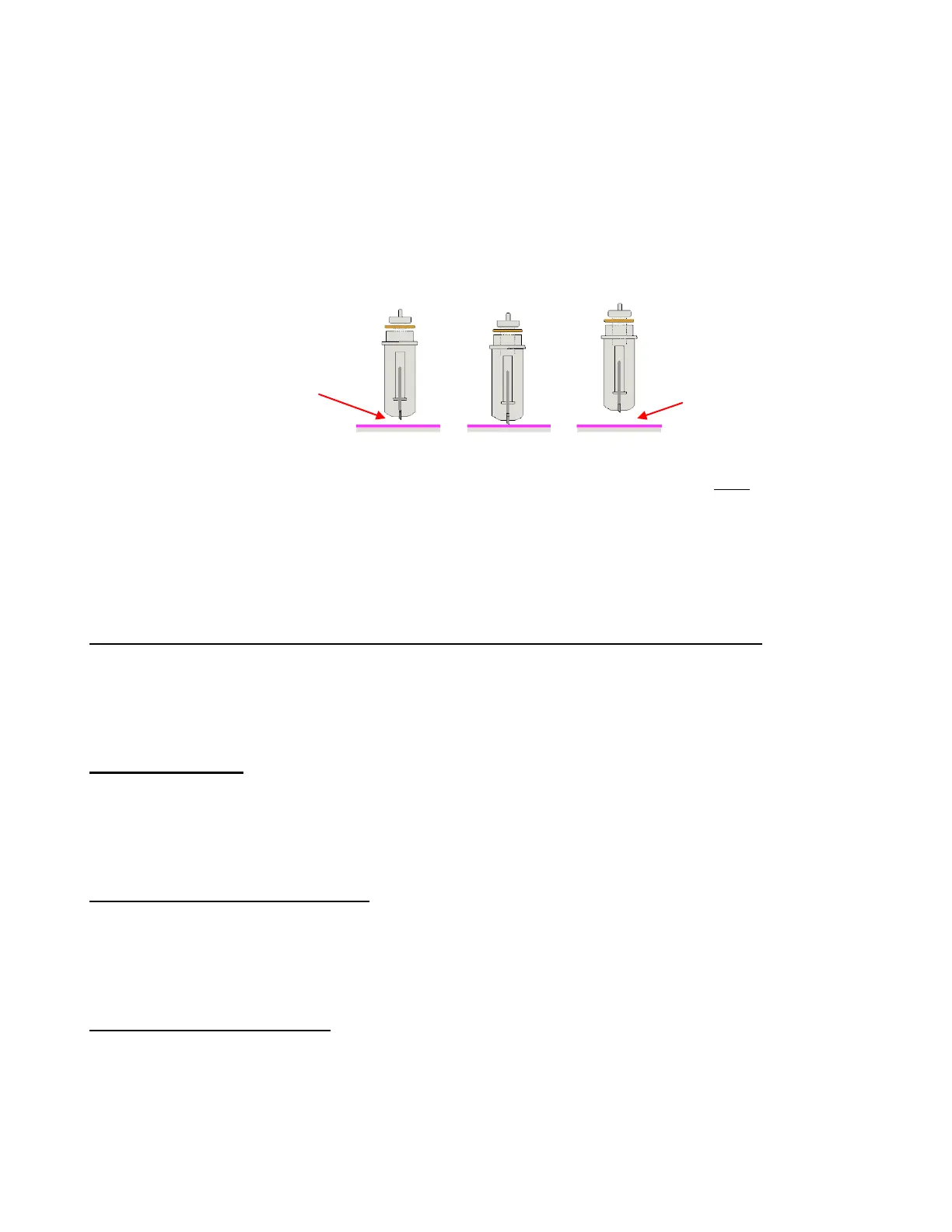

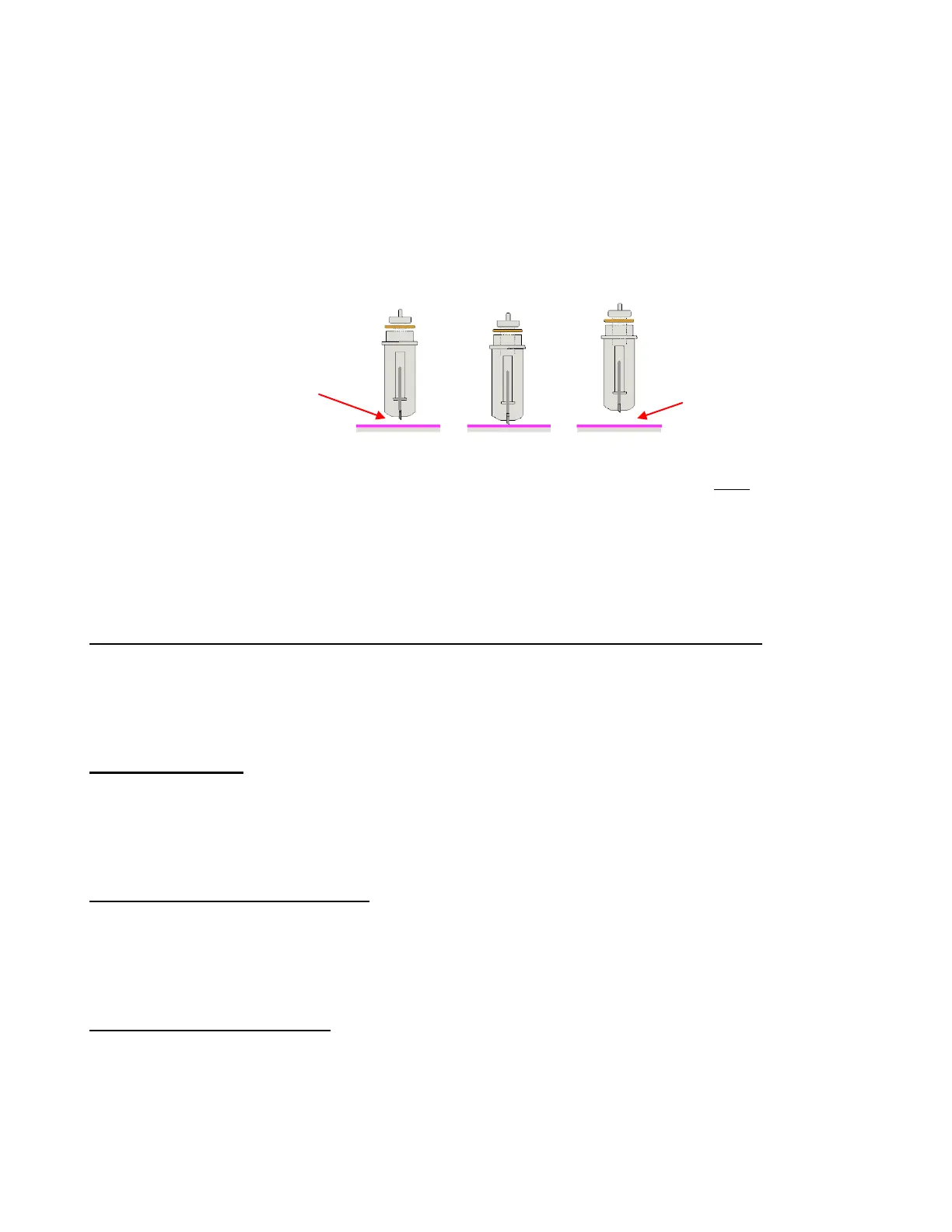

Perfect Height Too Low Too High

Blade tip

needs to be

above the

material

But not too high or

blade tip will not

reach the material

when dropped.

Loading...

Loading...