Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT ADJUSTMENT, INSPECTION AND REPLACEMENT)

Electrical Test

Voltage Test

Safety lanyard must be on DESS post.

Using the vehicle communication kit (VCK) with

the B.U.D.S. software, energize the fuel injector

from the Activation tab.

You should hear the injector working.

If the injector does not work, disconnect the con-

nector from the injector.

Install a temporary connector on the injector with

wireslongenoughtomaketheconnectionout-

side the bilge and apply voltage (12 V) to this test

harness.

CAUTION: While doing fuel injector electrical

test, do not apply continuous voltage to the

connector for more than 10 seconds. This can

damage the injector.

This will validate the injector mechanical and elec-

trical operation.

If it does not work, replace it. If it works, continue

procedure.

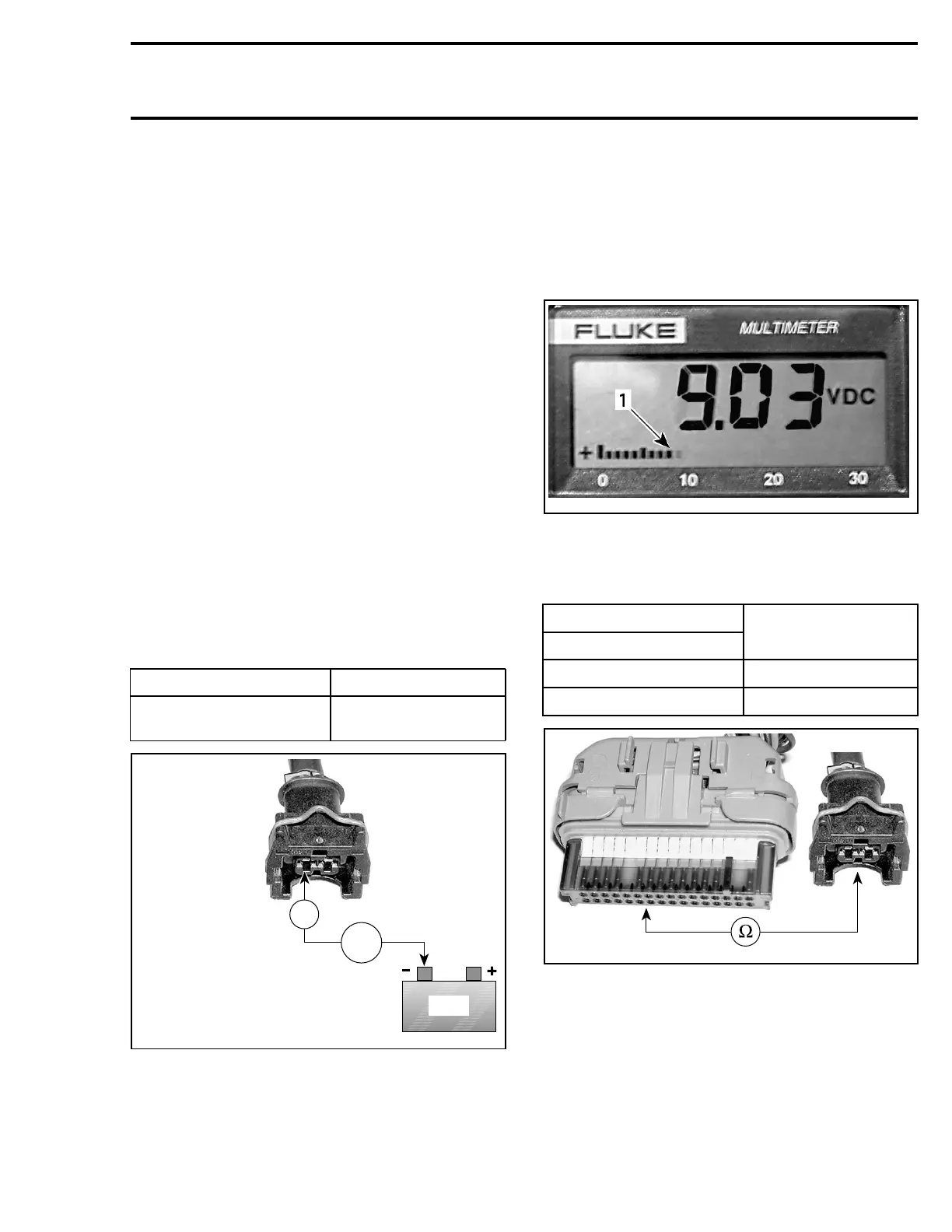

Using B.U.D.S., activate injector while probing ter-

minal as shown.

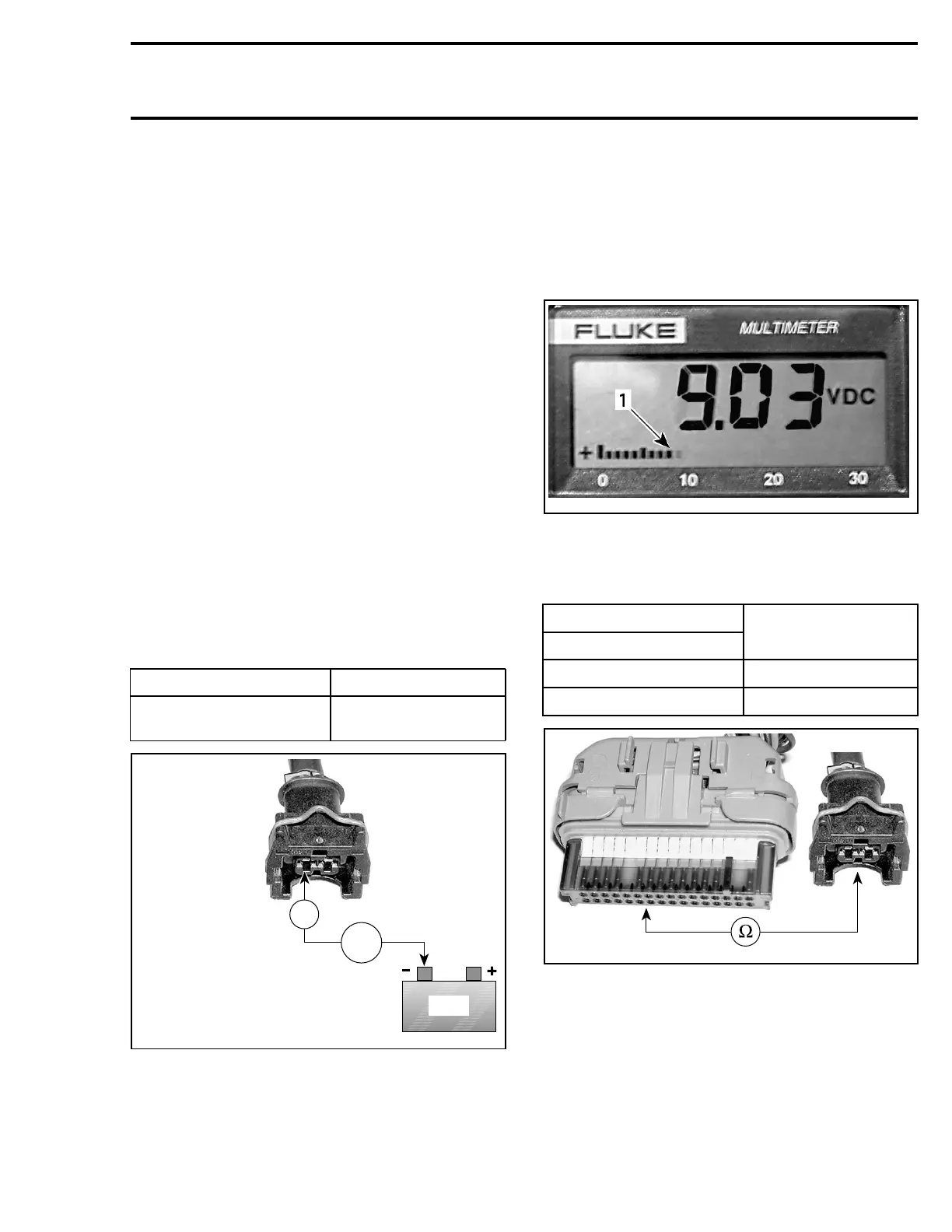

INJECTOR CONNECTOR MEASUREMENT

Pin 1 and battery ground

Pulsating voltage

approx 9 Vdc

BAT

Vdc

1

smr2005-056-011_a

NOTE: Because B.U.D.S. sends pulsating voltage

to the injector, you will not read full 12 V. Short

readings of approximately 9 V indicate a working

injector. Since the analog display of the multime-

ter is faster than the numeric display, watching the

analog scale movement is better to see voltage

bursts.

smr2005-056-010_a

1. Analog scale

– If proper voltage is read, check continuity of

ground and power circuits as follows.

VCM CONNECTOR

PIN

INJECTOR

5-32

1(MAG),pin2

5-16

2(PTO),pin2

smr2005-056-012_a

smr2005-056 133

Loading...

Loading...