3. Select "Next step >".

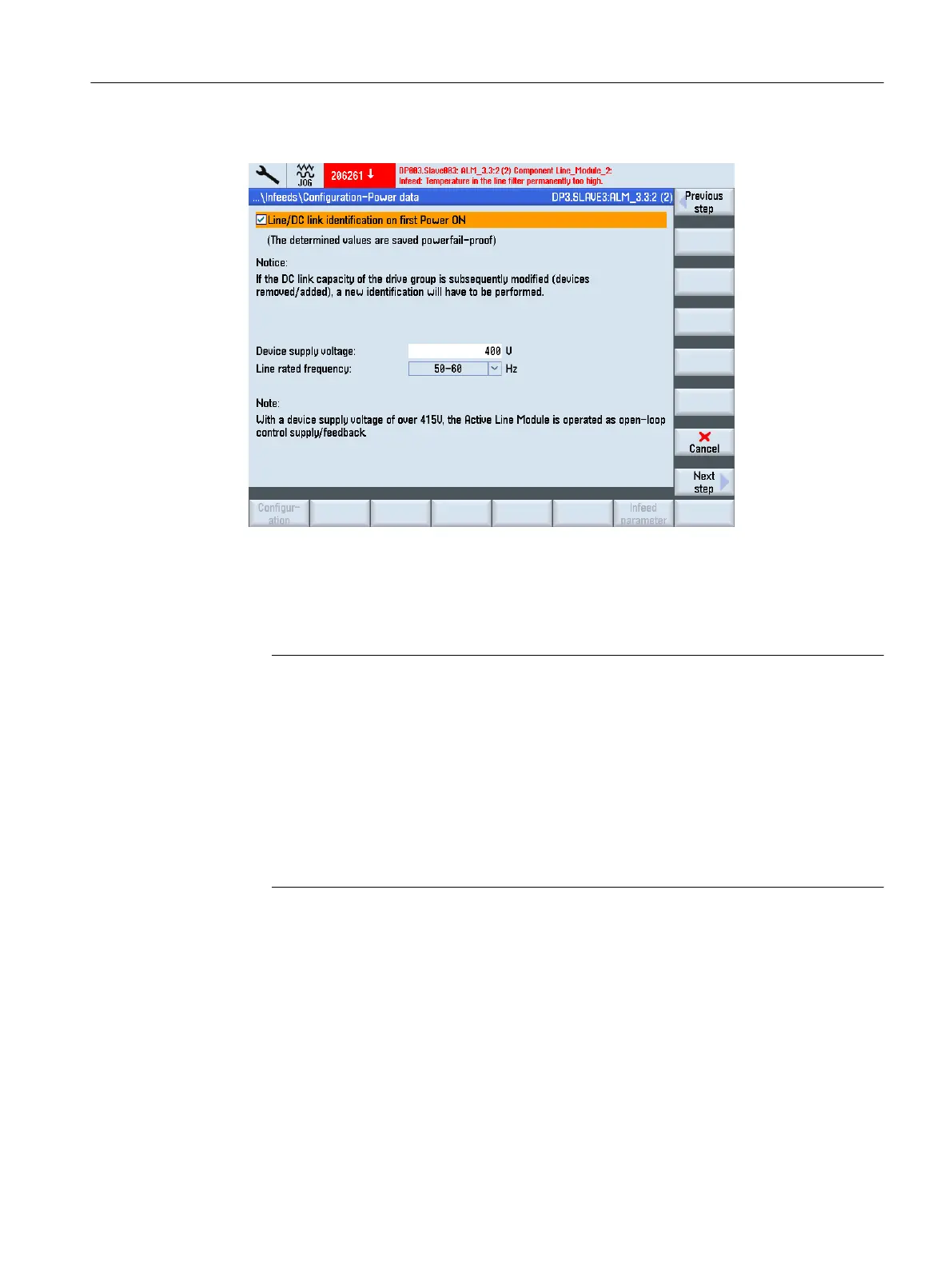

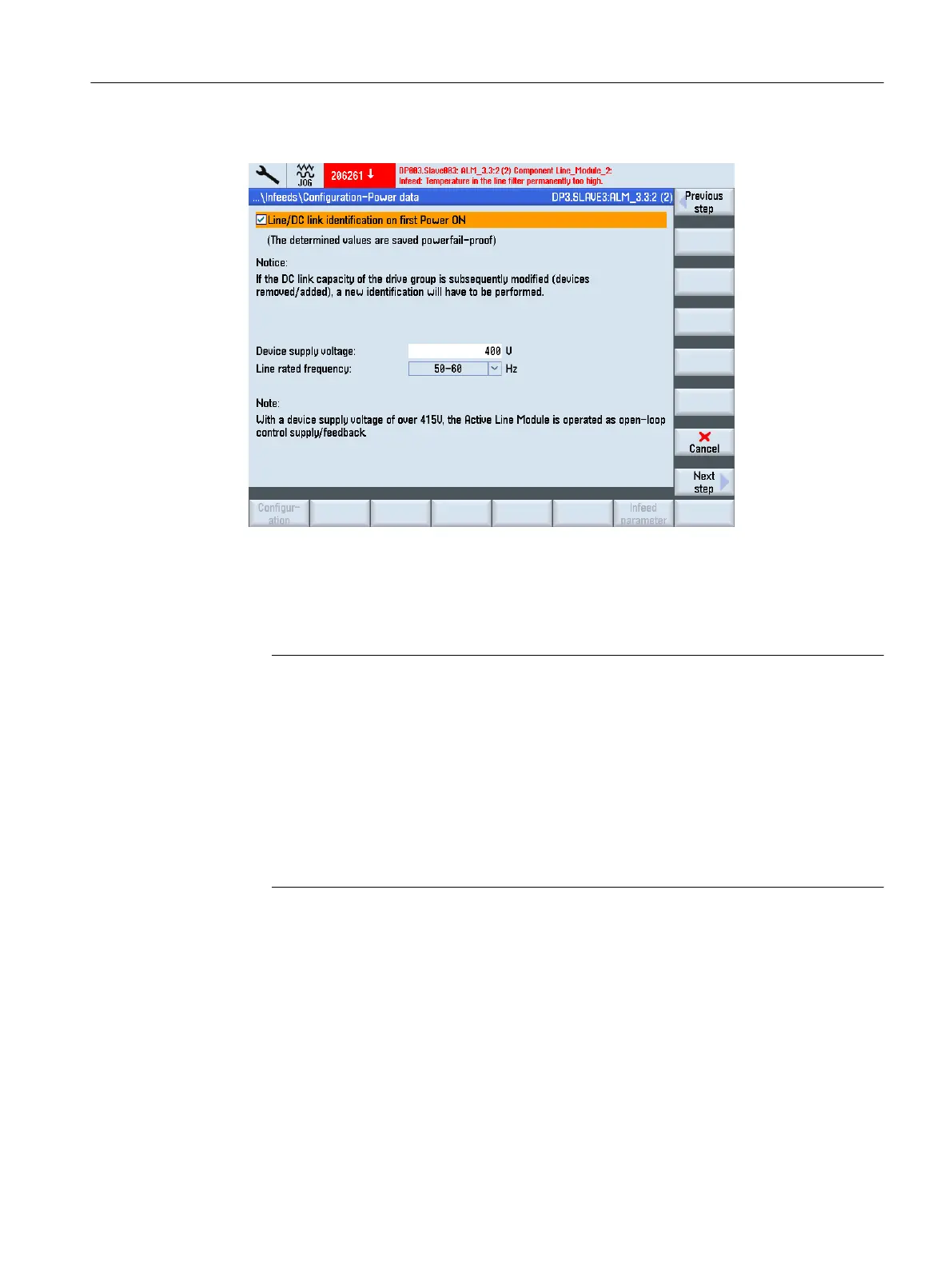

Figure 5-6 Infeeds > Line data

The following supply system data is configured:

– When selecting the checkbox,

the line/intermediate circuit identification is activated once

the pulse is enabled of the infeed (p3410). The infeed then switches to operational mode.

Note

DC link identification

If the line supply environment changes or the components on the intermediate circuit

change

(e.g.

after

setting

up the equipment at the customer site or after expanding the

drive group), the checkbox must be set again: Hence the "Supply system data" softkey

in the overview in order to restart the supply system / DC link circuit identification.

If p3410 = 5 is saved in the commissioning archive, then the supply system / DC link

identification starts automatically once the drive data is input into the archive.

Only then can it be guaranteed that the infeed operates with the optimum controller

settings.

– Enter the device supply voltage: This is the basis for monitoring the supply voltage

(p0281

-

p0283),

whereby

an alarm is triggered in the case of an overshoot or undershoot

(alarm threshold and shutdown threshold). The actual supply voltage is determined

automatically and the adjustment is made based on this value.

– The actual line frequency for the infeed is determined automatically.

– In parameter p0284, p0285, set a threshold above which an alarm is triggered (default

setting of the monitoring: 45 Hz to 65 Hz).

Commissioning the drive

5.1 Commissioning the drive

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 121

Loading...

Loading...