5. The first step with the first feedrate of the measurement series is selected. Enter the friction

compensation values in the following entry fields:

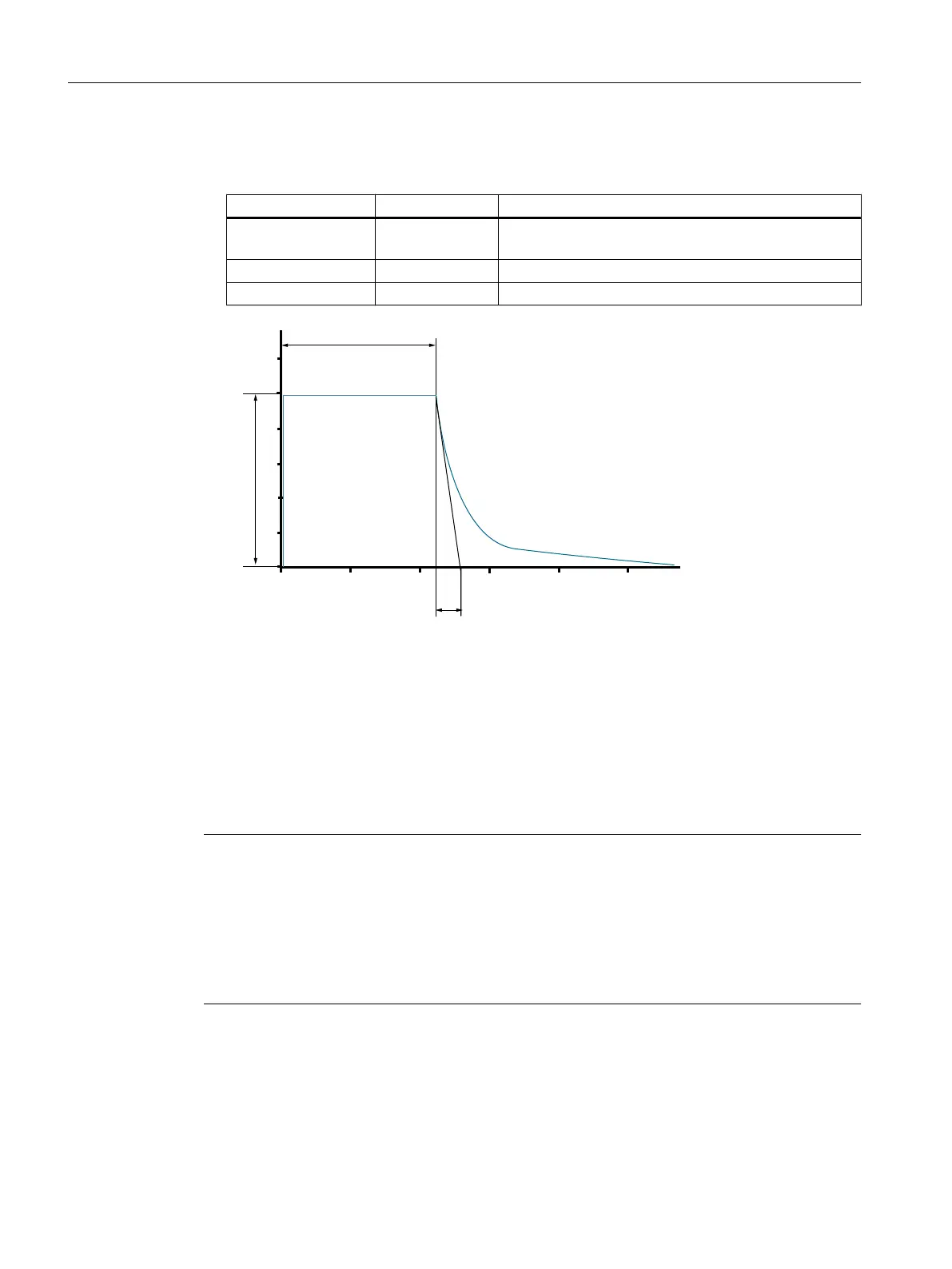

Input field Unit Machine data

Amplitude [mm/min]

or [°/min]

MD32571 $MA_FRICT_VELO_STEP

Decay time [s] MD32574 $MA_FRICT_V_PULSE_DECAY_TIME

Active time [s] MD32573 $MA_FRICT_V_PULSE_CONST_TIME

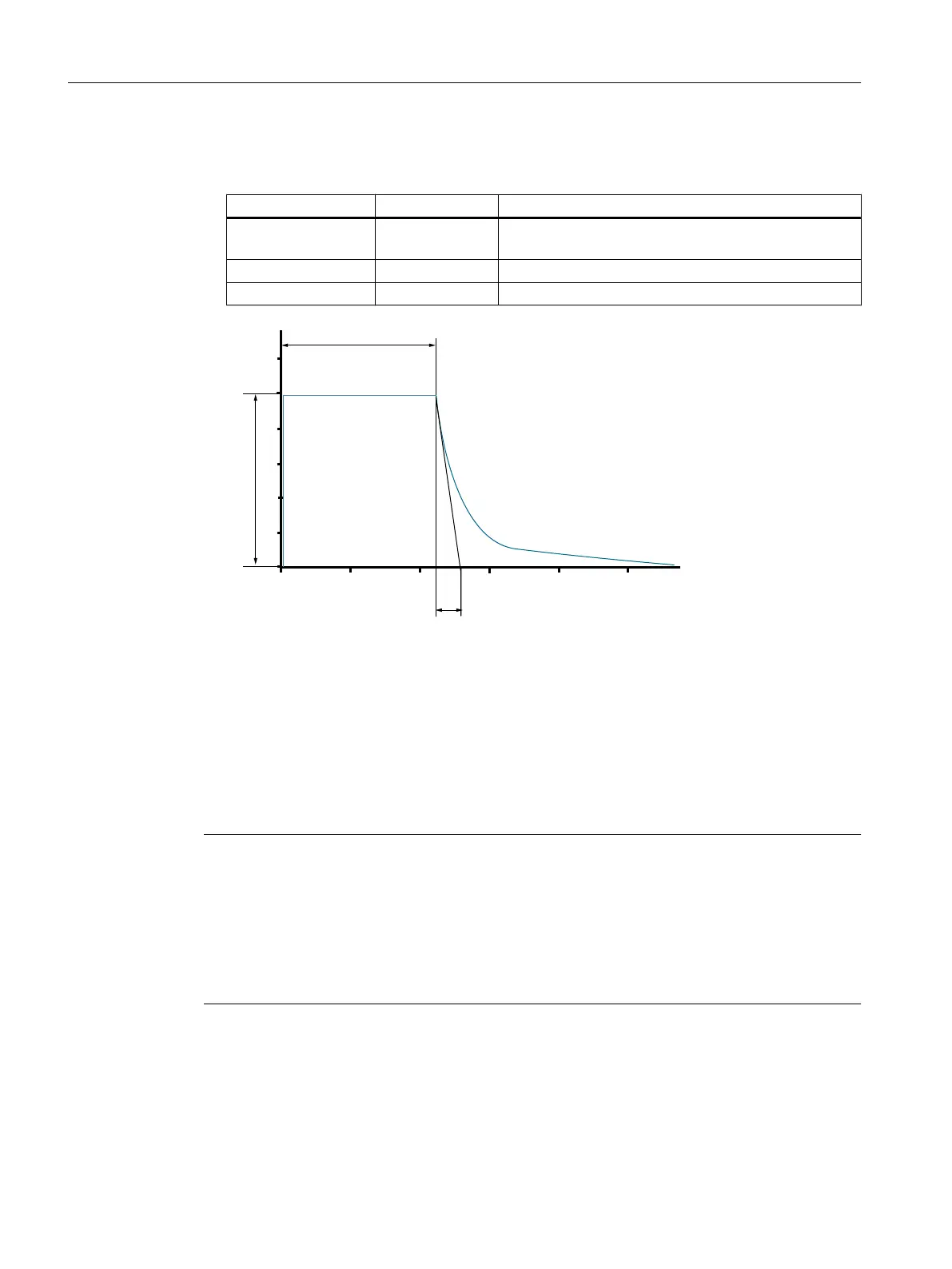

7LPHW>V@

0$B

)5,&7B9B38/6(B&2167B7,0(

0$B)5,&7B9B38/6(B'(&$<B7,0(

0$B)5,&7B9(/2B67(3

For both traversing directions, as default setting, the same compensation values are

entered. By selecting the option "Set reversal points separately", you can enter different

compensation values for an axis, depending on the particular traversing direction.

6. Press

the

"Next

step"

softkey to start a new measurement with the next feedrate and enter

new values. If the measurement is repeated, the values appropriate for the feedrate from

the last measurement are proposed.

After the last step, the measuring series is terminated with "OK" and the data is saved.

Note

Incremental value change

Use the following shortcut keys to change the compensation values incrementally:

● The selected entry field is activated with the <INSERT> key, and the color changes.

● The values

are changed with different increments with the <Page Up> / <Page Down> keys

and the ↑↓ cursor keys.

● End the input with the <INPUT> key.

⇒ Further actions:

● "Axis +" or "Axis

-" softkey to select the axis for which the friction compensation is activated.

● "Start" softkey to start the measurement.

● "Next step" softkey to select the next feedrate.

Tuning

6.7 Friction compensation with adaptive characteristics

CNC commissioning

218 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...