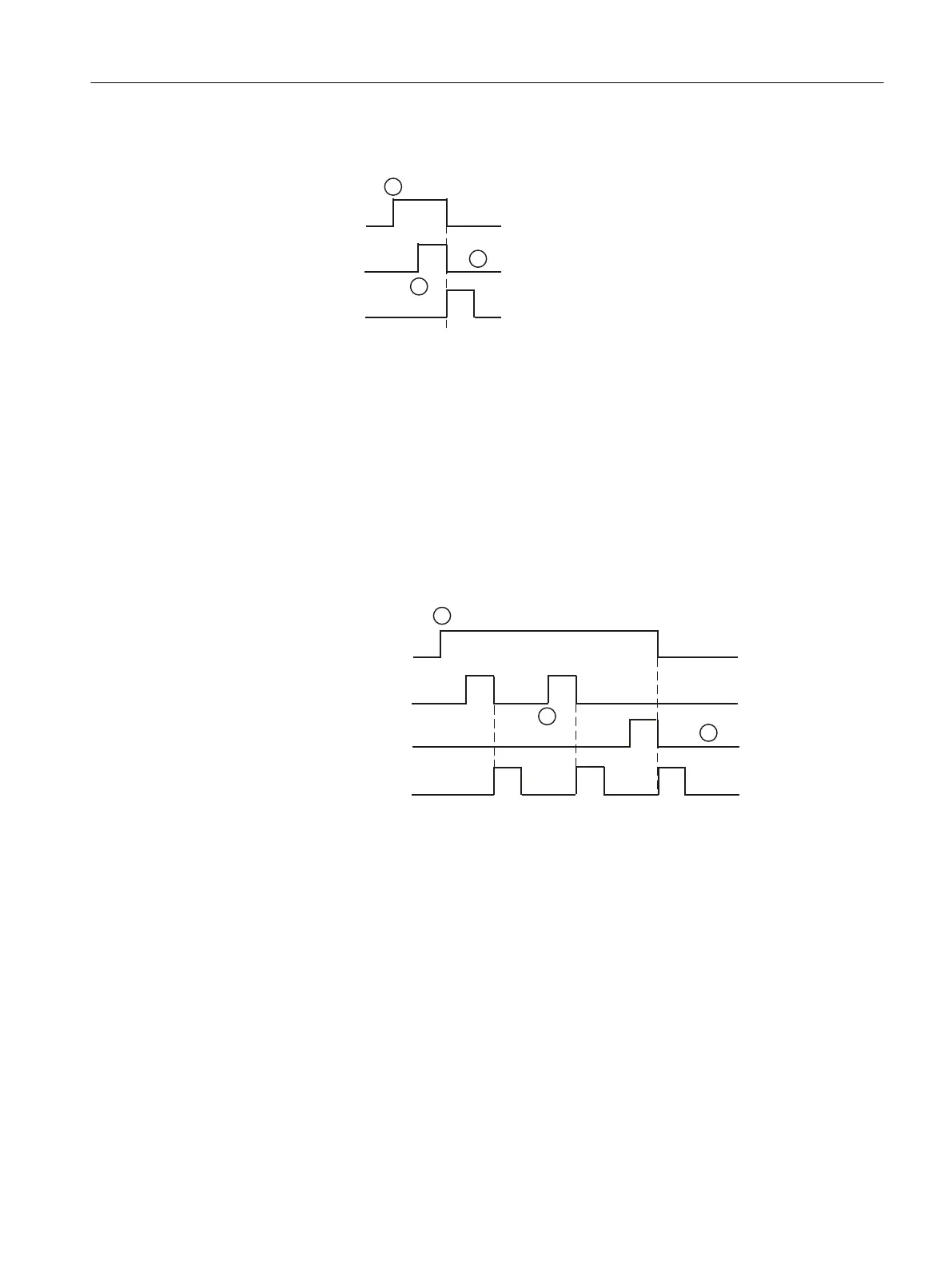

Typical sequence of any job with total acknowledgment

2U

GHU

$F

NQR

ZOH

GJPHQW2.

7RWDODFNQRZOHGJPHQW

Signal description:

① The PLC user program recognizes from the 0/1 edge of the signal DB43xx.DBX0.0 (job) that a

new job has been assigned by the tool management.

② The PLC user program sets the acknowledgment signal in DB42xx.DBX0.0 (total acknowledg‐

ment). With activation of

the 0/1 edge, the PLC firmware starts transferring the acknowledgment

to the tool management.

③ After successful transmission of the acknowledgment to the tool management, the PLC firmware

sets a PLC cycle to 1 for the signal "acknowledgment OK" and at the same time the job signal

and the acknowledgment bit are reset to 0.

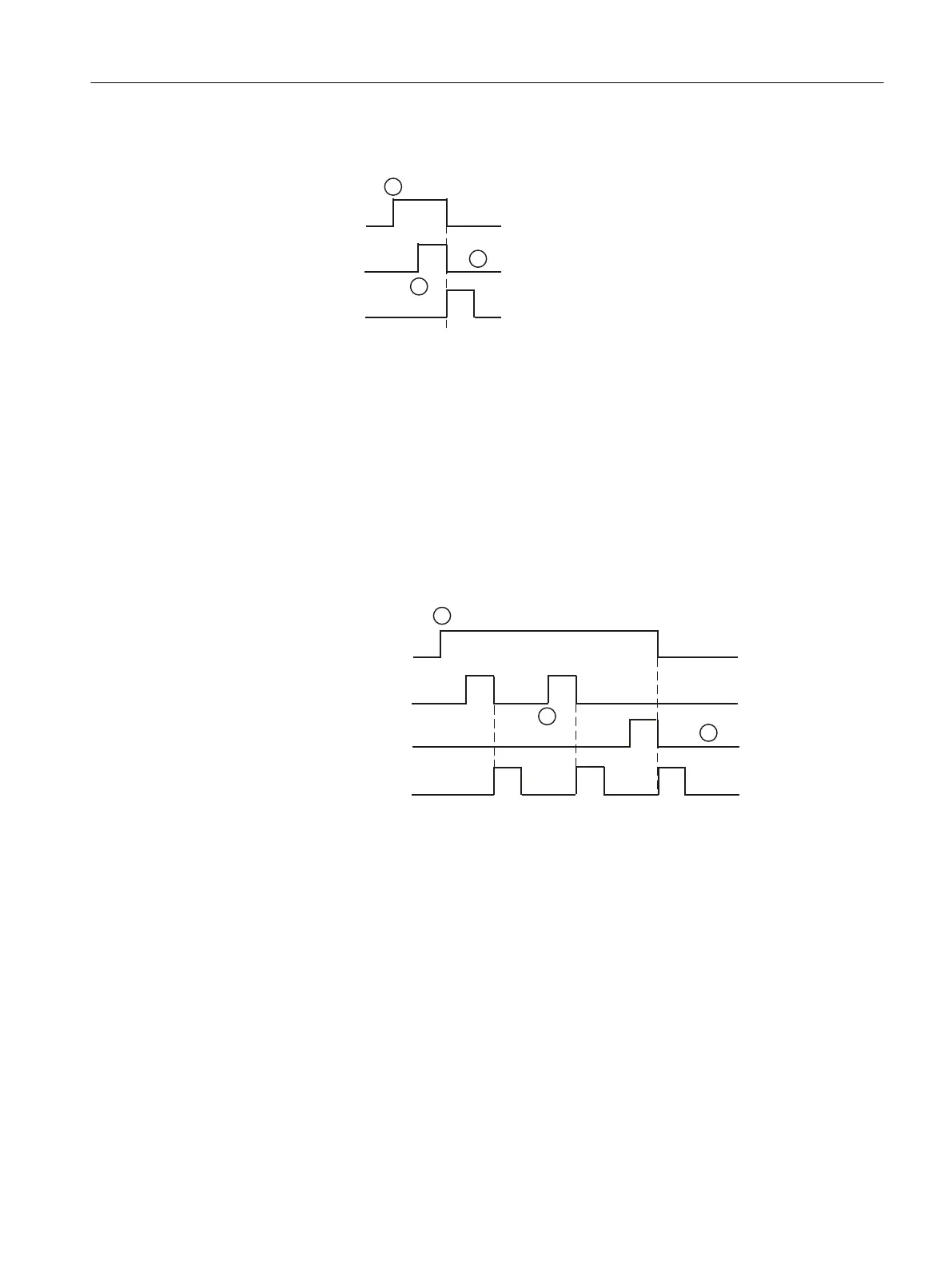

Typical sequence of any job with total acknowledgment and end acknowledgment

2UGHU

$FNQRZOH

GJPHQW2.

(QGDFNQRZOHGJPHQW

,QWHUPHGLDWHDFNQRZOHGJPHQW

Signal description:

① The PLC user program recognizes from the 0/1 edge of the signal DB43xx.DBX0.0 (job) that a

new job has been assigned by the tool management.

② The PLC user program acknowledges the transfer steps, configured in DB9900, DB9901 and

DB9902, with acknowledgment status 105. The tool management updates the tool positions

using the transfer steps of the acknowledgments.

③ The execution of the job is acknowledged by the PLC user program with acknowledgment status

1.

After successful transmission

of the acknowledgment to the tool management, the PLC firm‐

ware sets a PLC cycle to 1 for the signal "acknowledgment OK" and at the same time the job

signal and the acknowledgment bit are reset to 0.

Sequence of the tool management with block splitting (machine data setting milling)

Txx M6 ;

Tool management

9.4 PLC Program Blocks

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 287

Loading...

Loading...