Program L6 is called with M6 (basic setting)

3UHSDUHDW

RROFKDQJH

([HFXWHWRROFKDQJH

2UGHU

$FNQRZOHGJPHQW2.

(QGDFNQRZOHGJPHQW

,QWHUPHGLDWHDFNQRZOHGJPHQW

Signal description:

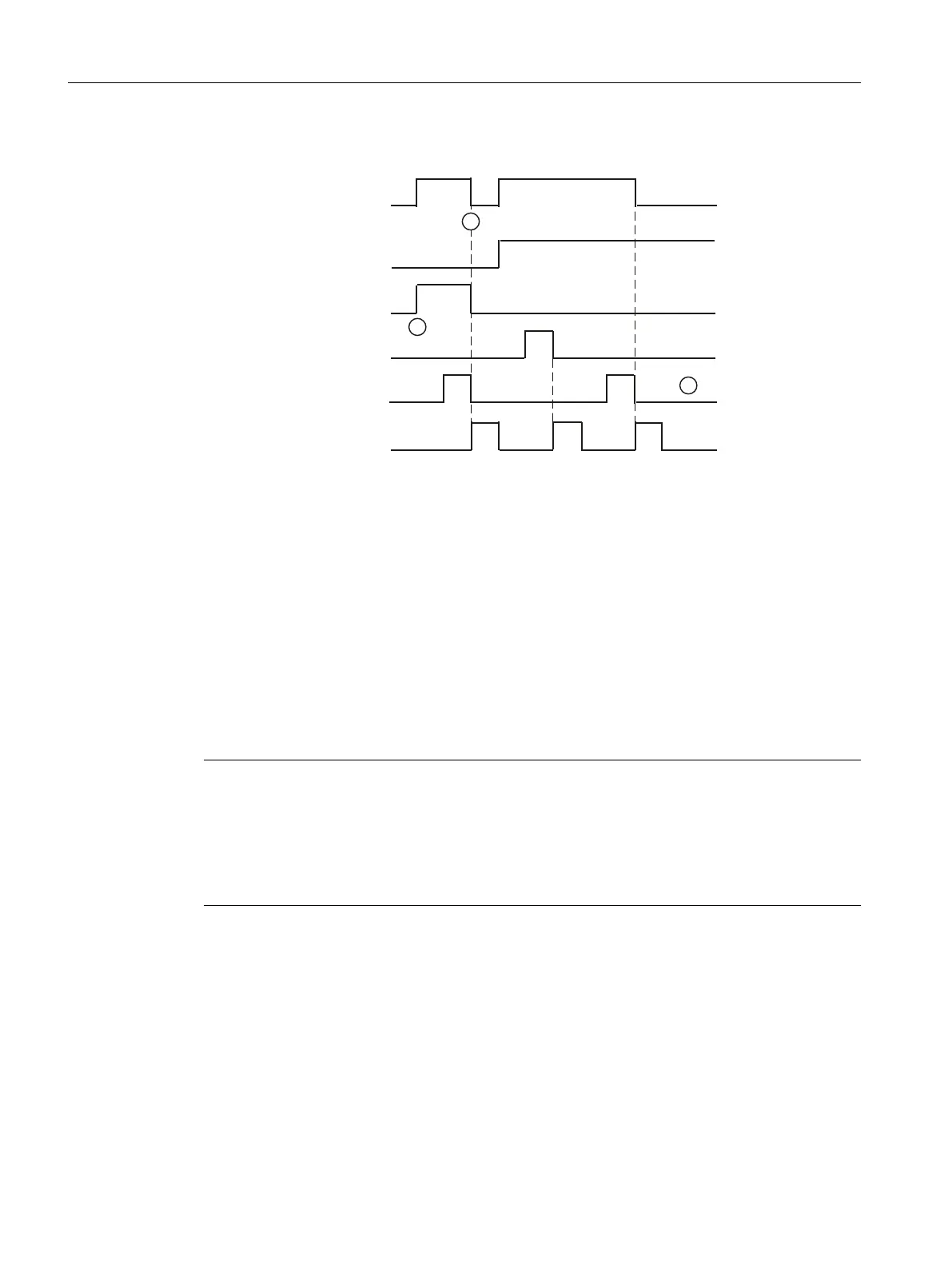

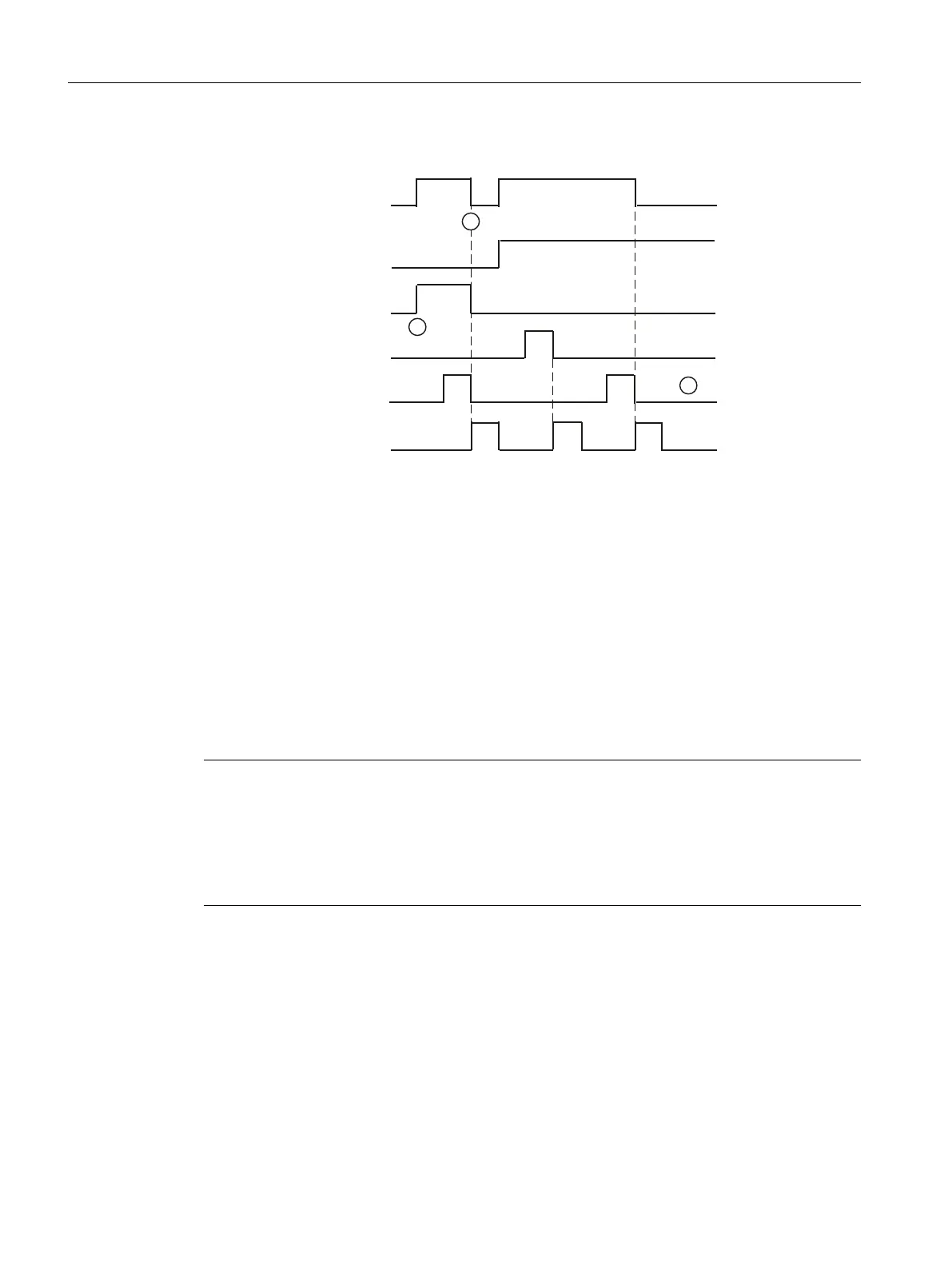

① The PLC user program receives a new job. The job "prepare tool change" and the job "execute

tool

change"

are

issued

one after the other. Txx and M206 have been programmed in separate

NC blocks. Only the job "prepare tool change" is present in the interface in DB43xx. The job

"execute tool change" is output only after the end acknowledgment for the job for tool prepara‐

tion.

② Bit DB43xx.DBX0.0 (job) is reset with acknowledgment of the "prepare tool change" job. If the

change command (M206) has

already run through the NC main run, the new job is immediately

output at the interface.

③ The "execute tool change" job is acknowledged as a normal job. The end acknowledgment OK

is returned and the bit for the job is simultaneously reset.

The description of the job ("execute tool change" and "prepare tool change") is not reset. Byte

1 of DB43xx is not overwritten until the next job.

Note

MD20270, MD20310:

The

response of the

interface in DB43xx.DBB1 and of NC block processing is affected by the

setting in MD20270: $MC_CUTTING_EDGE_DEFAULT and MD20310:

$MC_TOOL_MANAGEMENT_MASK bit 5, 6, 7, and 8.

This sequence described here corresponds to the presetting of the machine data.

Sequence of the tool management without block splitting (machine data setting milling)

Txx Myy ;

Myy is the setting from MD22560: $MC_TOOL_CHANGE_M_CODE

This type of programming is not recommended!

Tool management

9.4 PLC Program Blocks

CNC commissioning

288 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...