Configuring the transfer steps

Any changes to the tool and magazine positions must be communicated to the tool

management by the PLC user program. A table of all mechanical single movements which

should be acknowledged / communicated helps with this. For each tool transfer, the table

contains the corresponding tool

start and target position, or for positioning a magazine location

at a transfer point (change, load, unload point), the magazine position and the name of the

transfer point.

● The transfer steps 1 … 64 are permanently configured in TM_CTS (DB9900) and can be

changed only by reloading.

● The transfer steps 101 … 164 in TM_VTS (DB9901) can be completely or partially

overwritten by the PLC user program (e.g. by entering the current magazine location).

Coding for position from a job

In the constant transfer-step table, the locations of real magazines are not identified by their

actual values (e. g. 1/14 for magazine 1 location 14) but with symbolic values (0/1) or (0/2).

Otherwise the transfer-step table would be huge for large magazines.

These symbolic values have the following meaning:

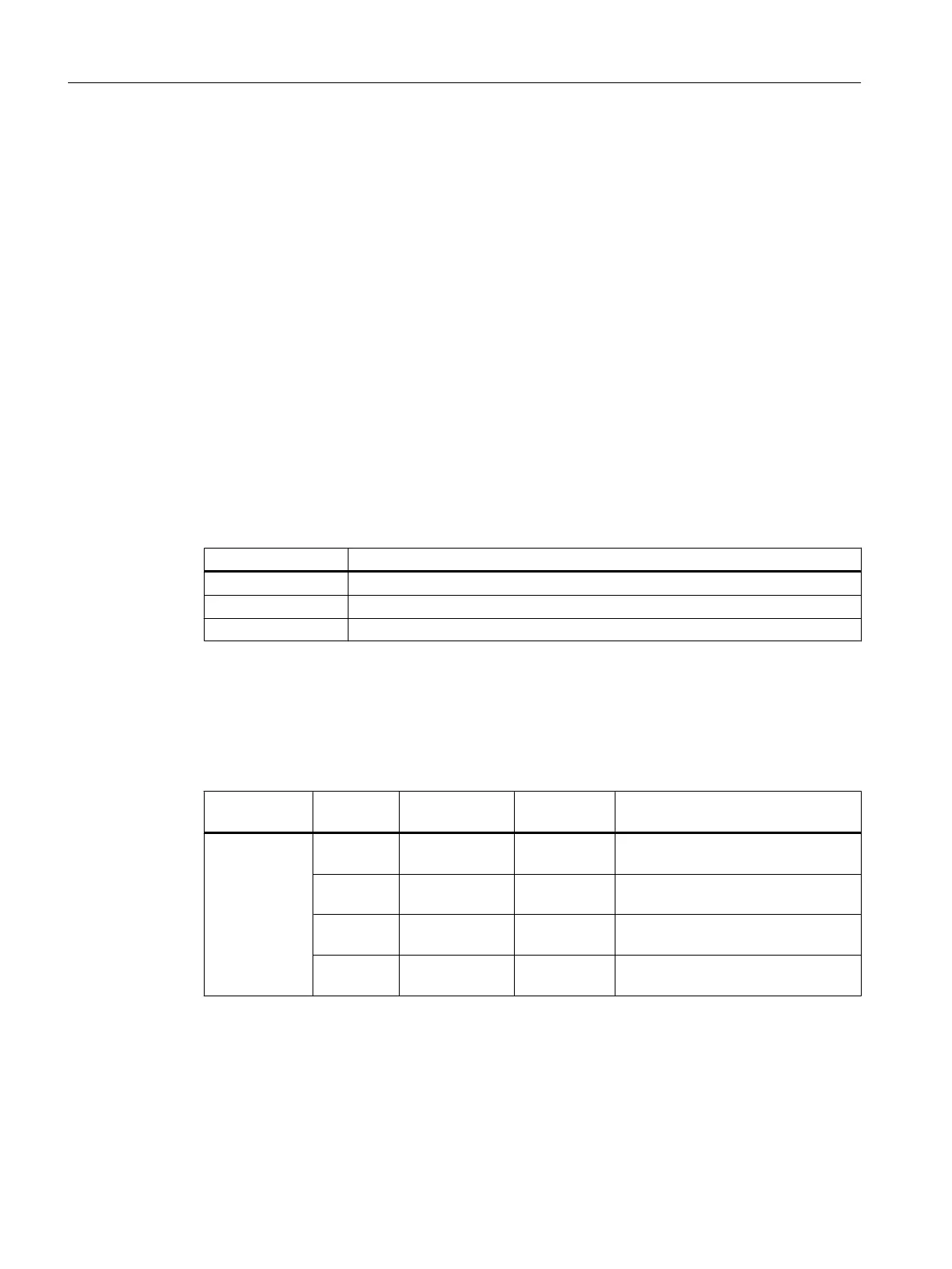

Magazine / Location Meaning

( 0 / 1 ) The source position of the only or new tool from the job should be used.

( 0 / 2 ) The target position of the old tool from the job should be used.

( 0 / 3 ) The target position of the only tool or new tool from the job should be used.

This symbolic notation form can only be used for synchronous intermediate and end

acknowledgments, since asynchronous messages do not have a job as a reference.

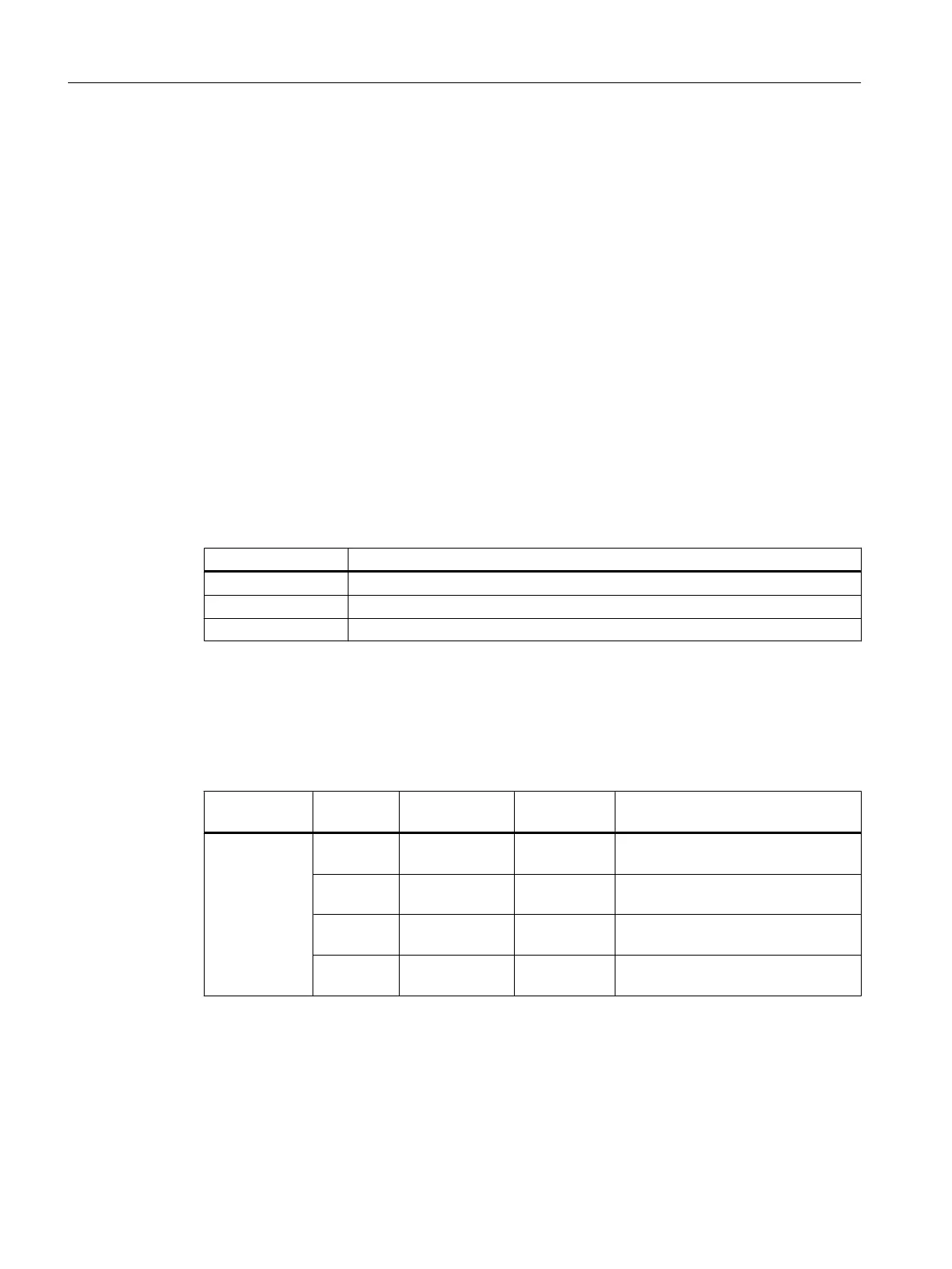

Example: Constant transfer-step table

Transfer step Address

DB9900

Name Start value Comment

1 0.0 SrcMag_1 0 Source magazine number of the

transfer step

2.0 SrcPos_1 1 Source position number of the trans‐

fer step

4.0 DstMag_1 0 Target magazine number of the

transfer step

6.0 DstPos_1 1 Target position number of the trans‐

fer step

Tool management

9.4 PLC Program Blocks

CNC commissioning

290 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...