For plane selection when milling, appropriately set the following machine data:

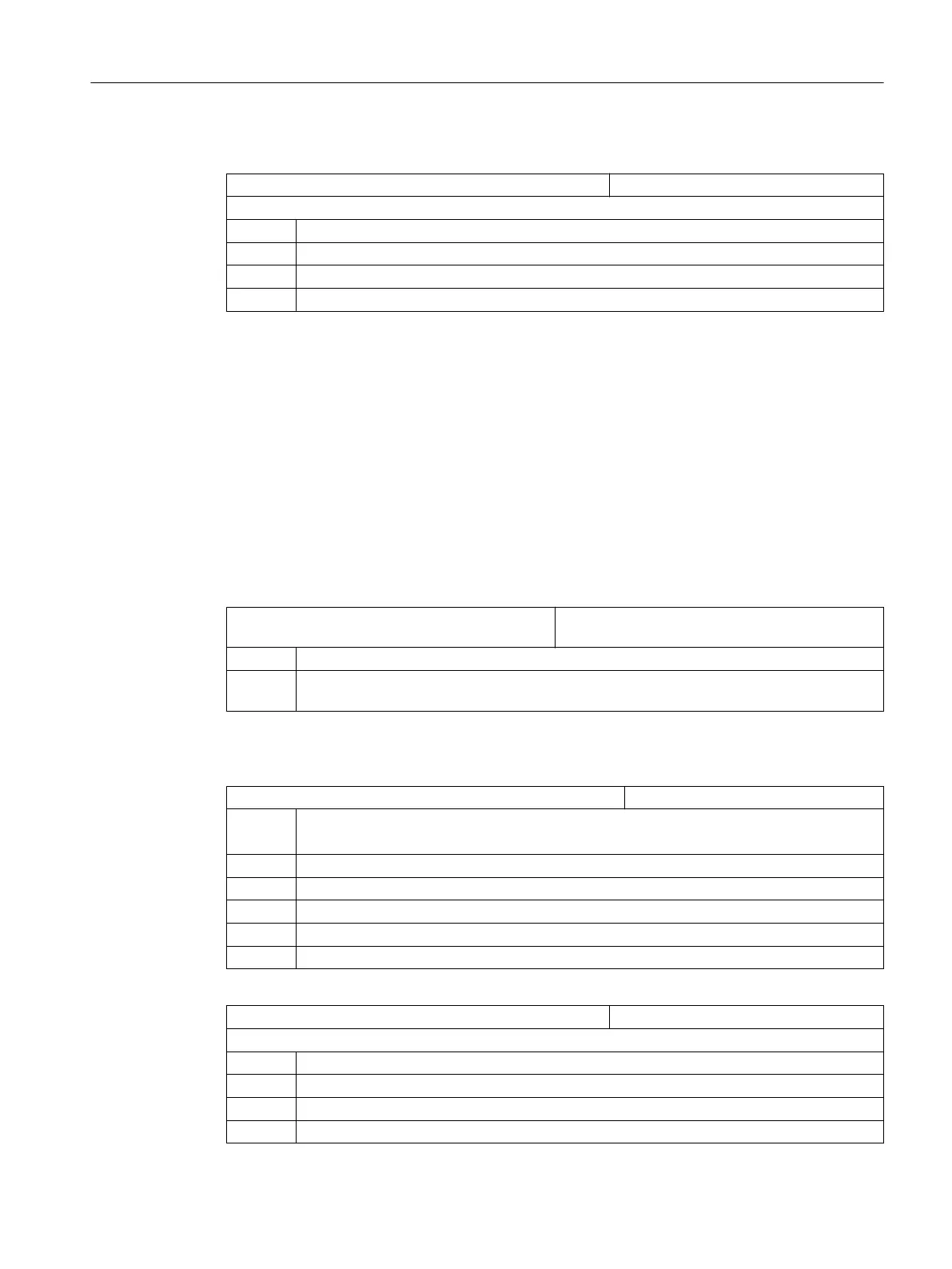

MD52005 $MCS_DISP_PLANE_MILL Plane selection for milling

= 17

= 0 In the cycle support

= 17 G17 (default value)

= 18 G18

= 19 G19

Simulation and simultaneous recording

In order that simulation and simultaneous recording are displayed without any errors, set the

machine data as described in the following section:

Setting the technology for simulation

(Page 67)

Defining the direction of rotation

In order that the direction of rotation is correctly displayed in the ShopMill user interface, and

when

programming

ShopMill

functions, the correct direction of rotation is executed, you must

make some settings that are coordinated with one another. You must align these settings to

the actual direction of rotation of the axis at the machine.

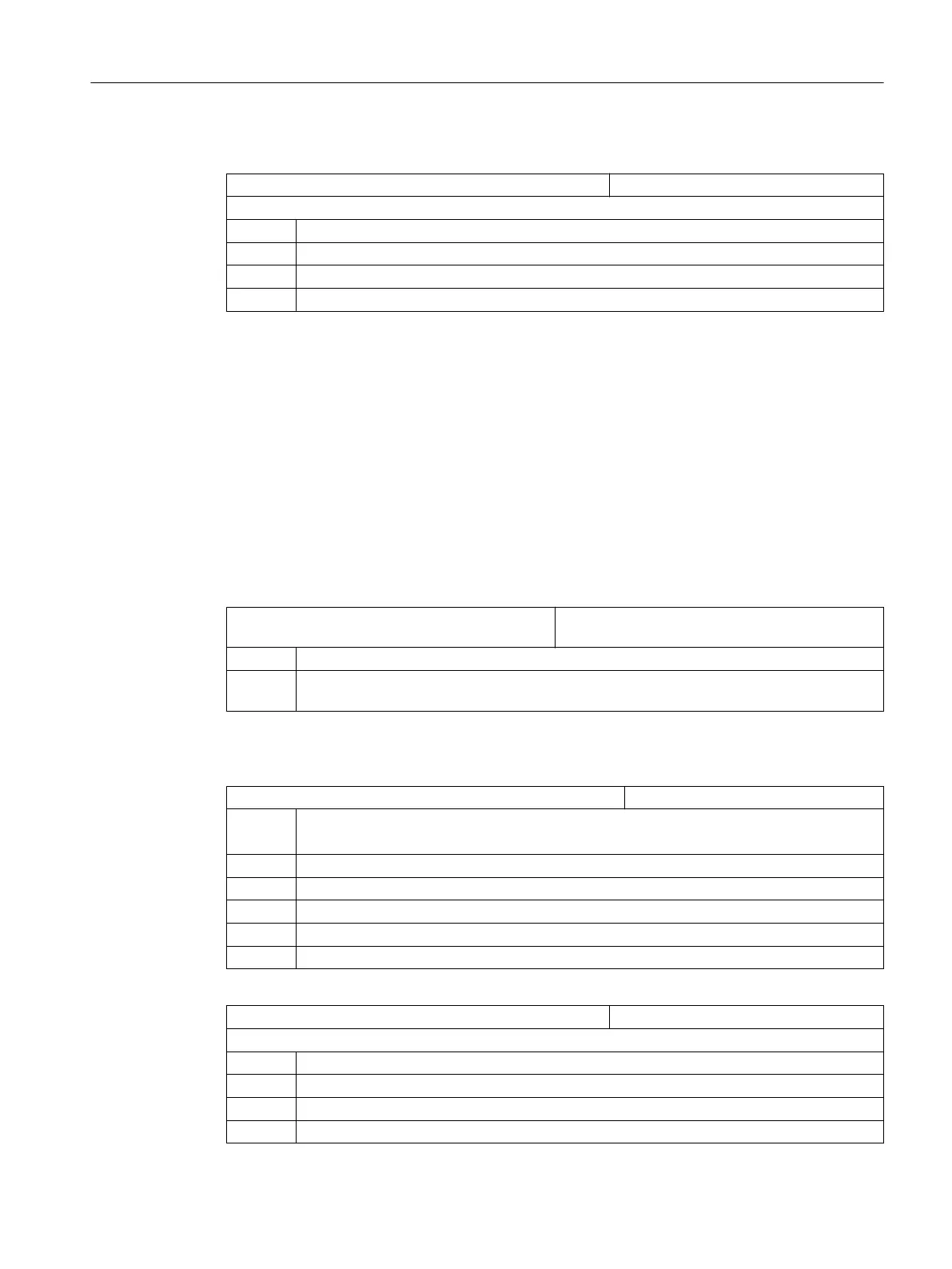

MD52207 $MCS_USAGE_ATTRIB[n] Attribute of the axes in the channel

[n] channel axis number

Bit 4 Displayed direction of rotation for M3 is counter-clockwise (for spindles)

Bit 5 Direction of rotation M3 corresponds to rotary axis minus (for spindles)

This bit must be set analog to PLC bit DB38xx.DBX2001.6.

Additional channel-specific machine data

MD52216 $MCS_FUNCTION_MASK_DRILL Drilling function screen form

Bit 2 Tapping also without encoder

The

setting depends on

whether at the machine the tool spindle is equipped with an encoder.

= 0 Tapping only possible with encoder

= 1 Tapping also possible without encoder

Bit 3 Constant cutting speed referred to the diameter of the centering

= 0 Constant cutting speed referred to the diameter of the tool

= 1 Constant cutting speed referred to the diameter of the centering

MD52229 $MCS_ENABLE_QUICK_M_CODES Enable fast M commands

= 0

Bit 0 Coolant OFF (default value)

Bit 1 Coolant 1 ON

Bit 2 Coolant 2 ON

Bit 3 Coolants 1 and 2 ON

Configuring cycles

7.4 Milling

SINUMERIK Operate

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 97

Loading...

Loading...