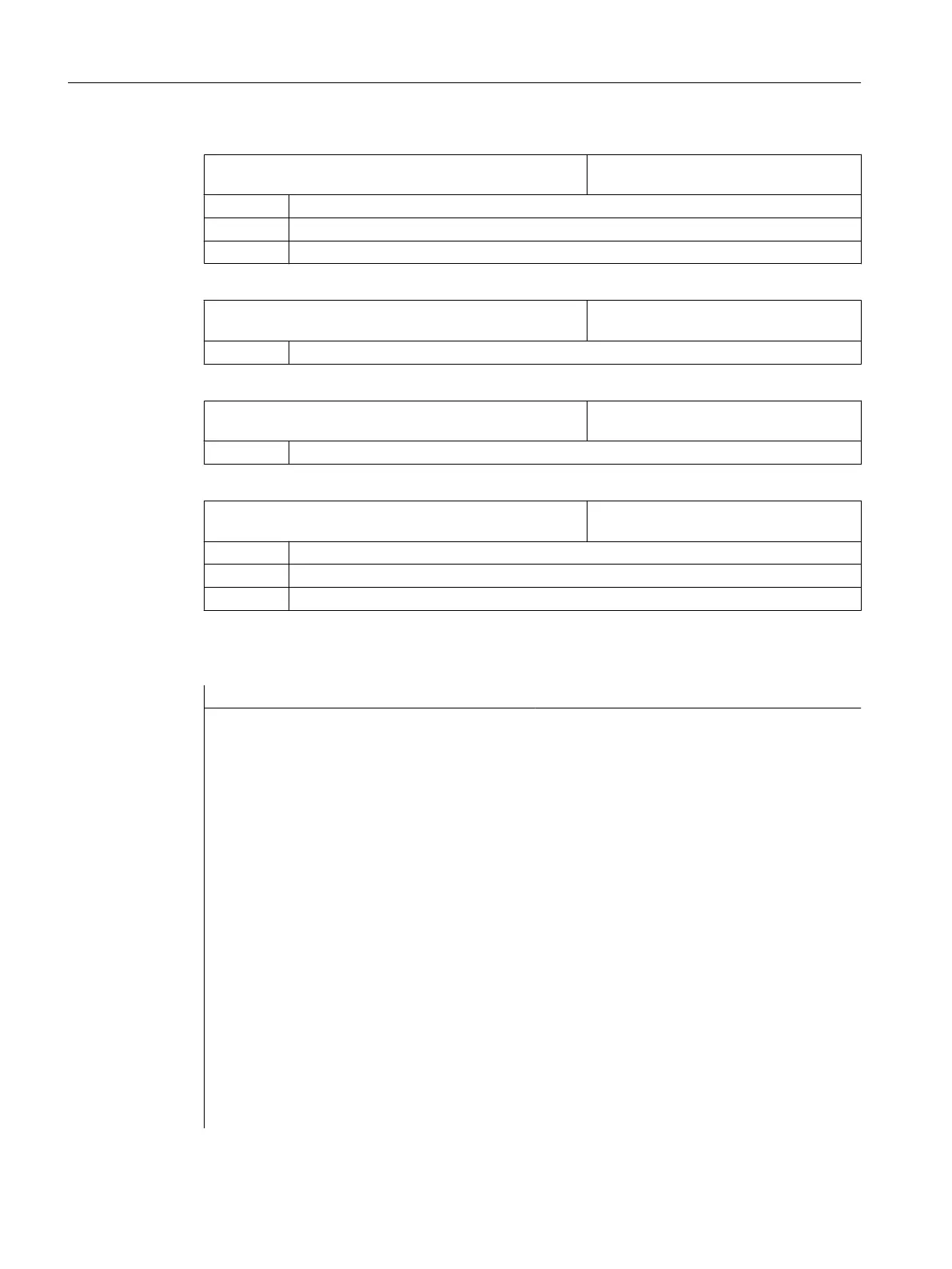

MD24220 $MC_TRAFO_GEOAX_ASSIGN_TAB_2[ ] Assignment of geometry axes to channel

axes for transformation 2

[0] = 6 6th channel axis becomes GEOAX X with TRACYL

[1] = 2 2nd channel axis becomes GEOAX X with TRACYL

[2] = 3 3rd channel axis becomes GEOAX X with TRACYL

MD24850 $MC_TRACYL_ROT_AX_OFFSET_2 Offset of the rotary axis for the 2nd TRAC‐

YL transformation

= 0 Offset of rotary axis from home position

MD24860 $MC_TRACYL_ROT_SIGN_IS_PLUS_2 Sign of the rotary axis for the 2nd TRAC‐

YL transformation

= 0 Sign of rotary axis

MD24870 $MC_TRACYL_BASE_TOOL_2[ ] Vector of the base tool for the 2nd TRAC‐

YL transformation

[0] = 0 Tool basic offset in X

[1] = 0 Tool basic offset in Y

[2] = 0 Tool basic offset in Z

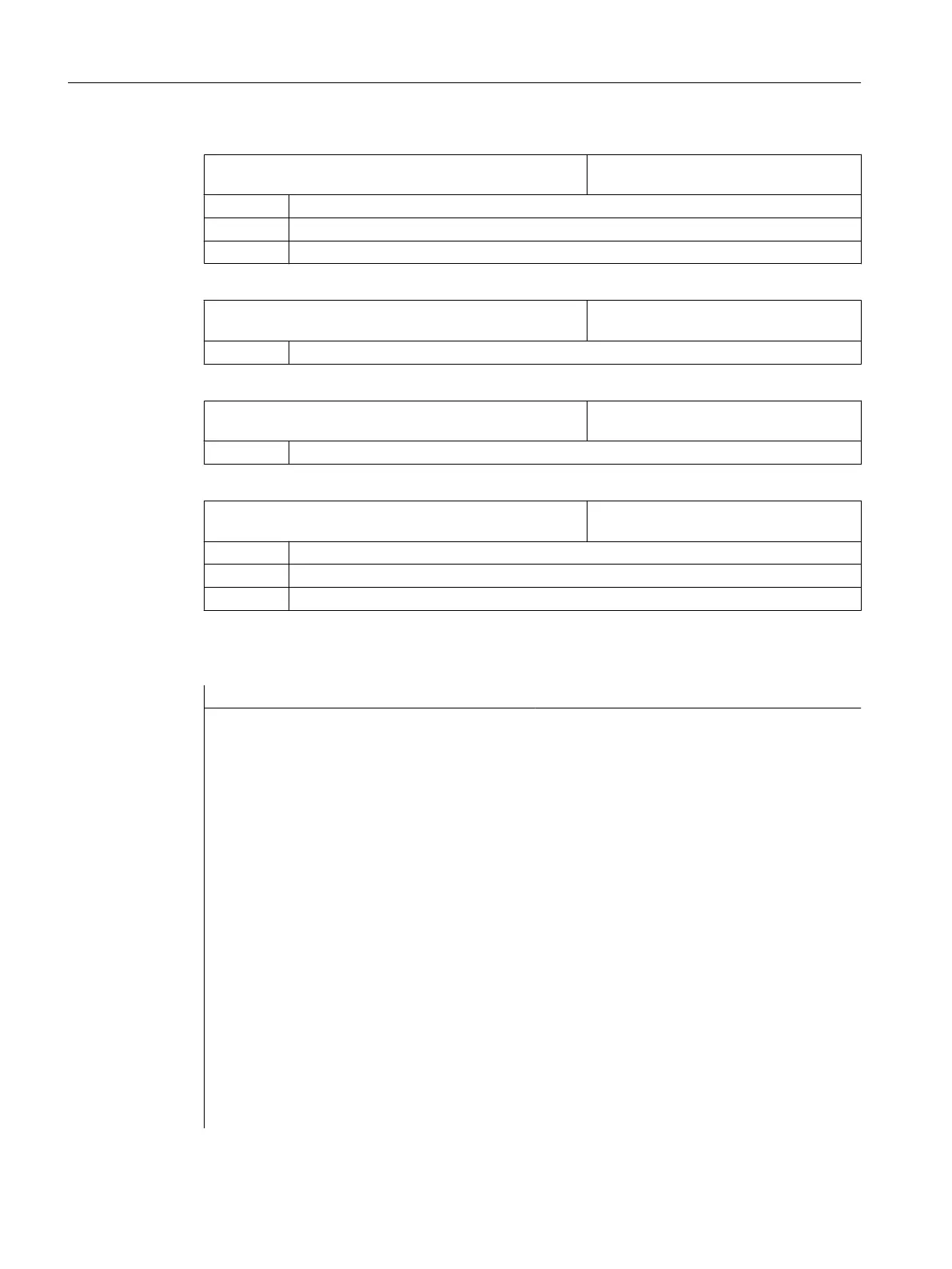

Example part program

Program code Comment

WORKPIECE(,"",,"CYLINDER",

0,0,-180,-80,179)

;blank definition

N10 M3 S2000 ;spindle speed defined

T="SLOTMILL" M6 D1 ;tool selection

N20 G0 G54 X0 Y-20 Z105 ;positioning

CYCLE800(0,"TABLE",

100000,57,0,0,0,-90,0,0,0,0,0,-1,100,1)

;rotate A-axis with swivel cycle

N40 G17 G90 ;machining plane defined

N70 G0 Y-10 Z100 G40 ;positioning

N74 TRACYL(179, 2) ;selection of TRACYL data set 2 with

groove wall offset

OFFN=20 ;offset defined (half groove width)

N80 G1 F500 X0 Z75 G42 ;starting point and milling radius offset

defined

N90 G1 Y50 ;groove center path

N112 X-60 ;groove center path

N114 X0 ;groove center path

N116 Y-10 ;groove center path

N130 G1 Z105 G40 ;retraction and deselection of milling

radius offset

Configuring cycles

7.4 Milling

SINUMERIK Operate

102 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...