Supplementary conditions:

● MD52200 $MCS_TECHNOLOGY = 2 (milling)

● MD52201 $MCS_TECHNOLOGY_EXTENSION = 0

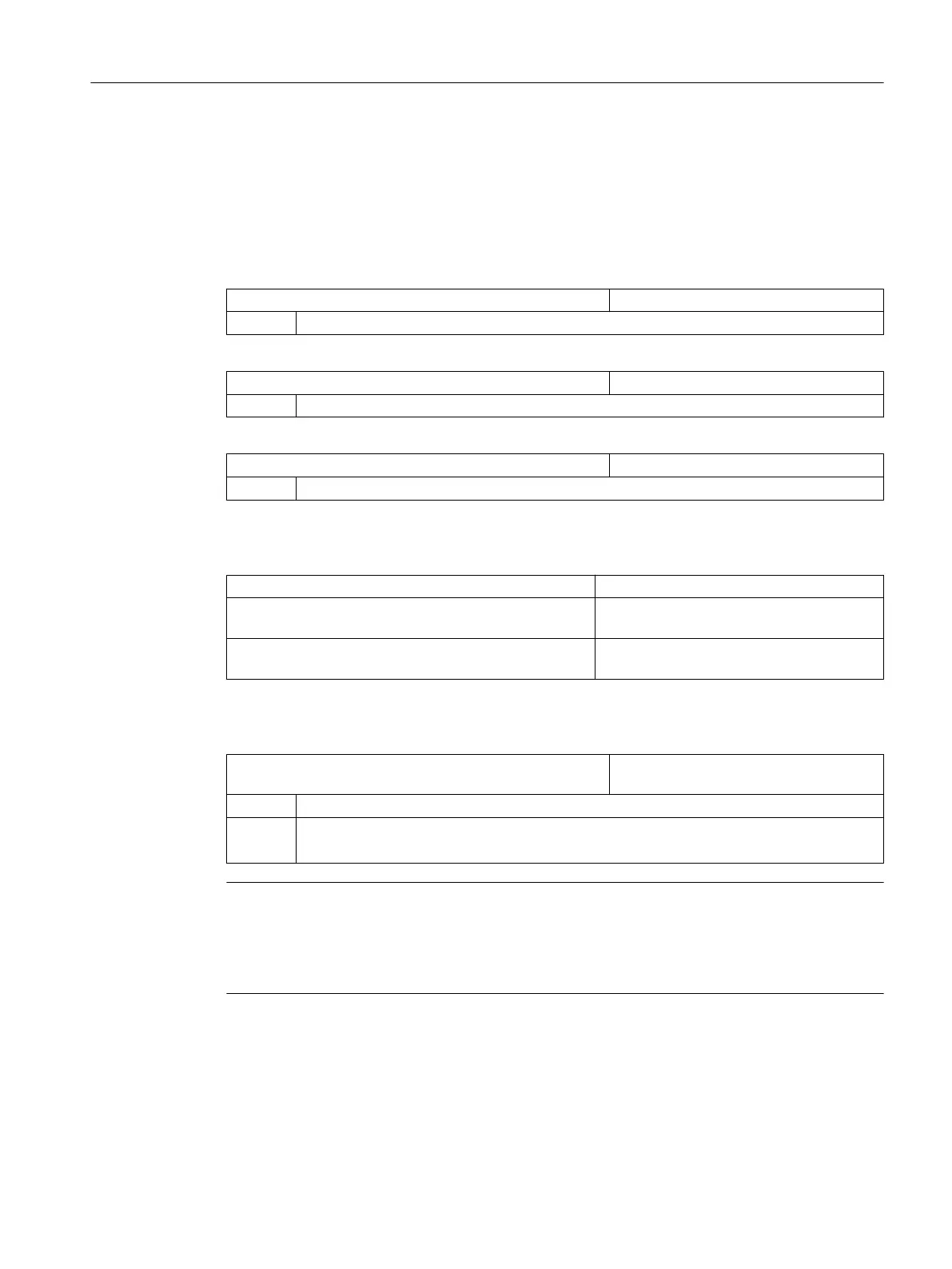

Default settings for unloading/loading and relocating

MD52272 $MCS_TM_TOOL_LOAD_DEFAULT_MAG Default magazine for loading tools.

= 0

No default magazine, default value

MD52273 $MCS_TM_TOOL_MOVE_DEFAULT_MAG Default magazine for relocating tools.

= 0 No default magazine, default value

MD52274 $MCS_TM_TOOL_LOAD_STATION Number of loading station.

= 0 All configured stations are considered, default value

Input limits for wear input

MD51212 $MNS_TM_WRITE_WEAR_ABS_LIMIT Maximum value of the tool wear.

MD51213 $MNS_TM_WRITE_WEAR_DELTA_LIMIT Maximum differential value of restricted tool

wear input.

MD51214 $MNS_TM_WRITE_LIMIT_MASK Range of validity of the restricted tool wear

input.

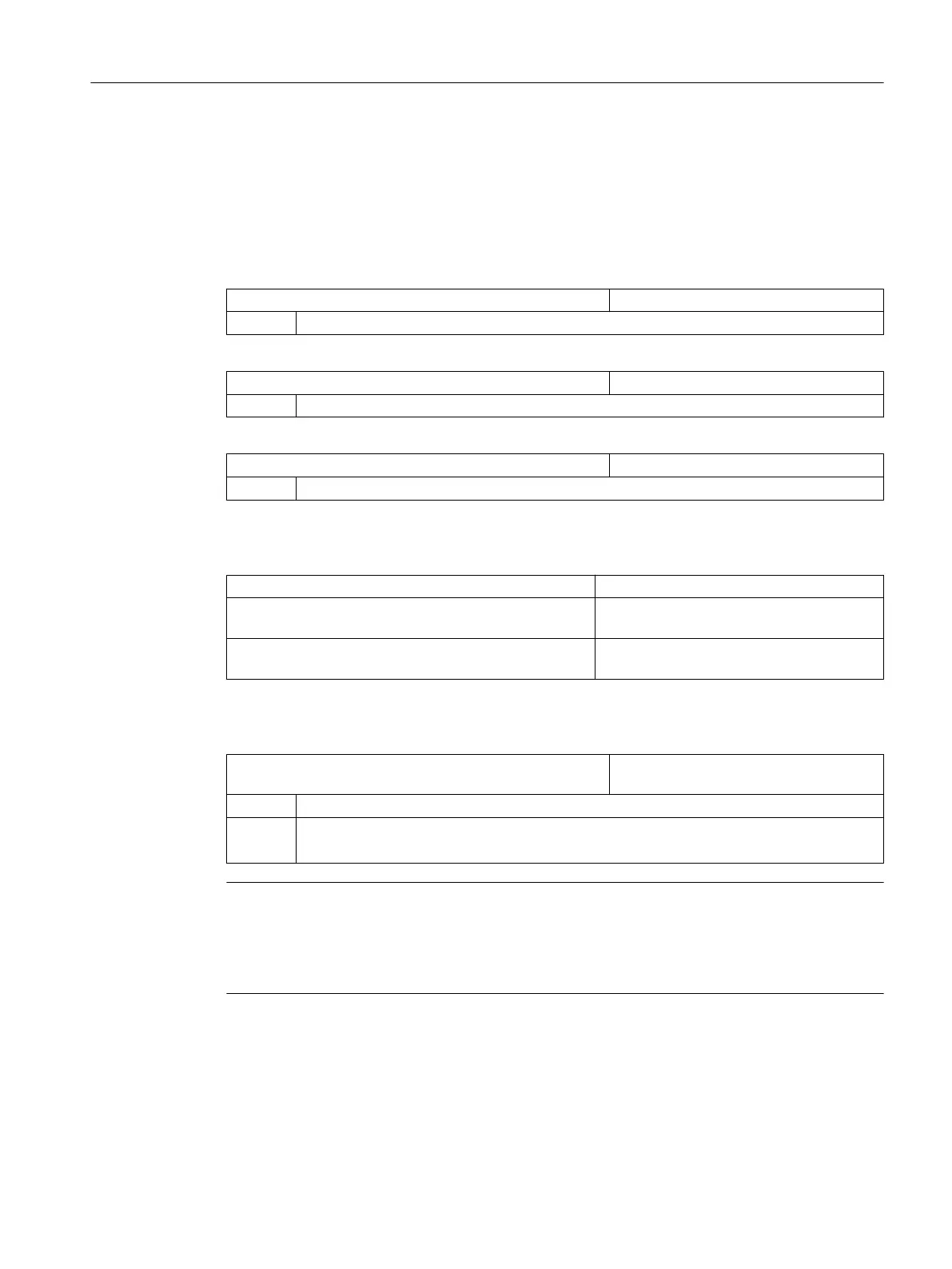

Setting the manual tool function

MD22562 $MC_TOOL_CHANGE_ERROR_MODE Response when errors occur at tool

change.

Bit 1 = 1 Manual tools can be loaded.

Bit 2 = 1 Active D No. > 0 and active T No. = 0 generate an alarm message.

Active D No. > 0 and active D No. = 0 generate an alarm message.

Note

If, in machine data

MD22562 $MC_TOOL_CHANGE_ERROR_MODE bit 2 = 1, then you have

the option, using a correction selection (D No.) in the program, to stop the machine until the

PLC signals that the tool change has been completed. To do this, machine data MD20270

$MC_CUTTING_EDGE_DEFAULT must be set to = 0.

Tool management

9.1 Machine data for tool management

SINUMERIK Operate

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 227

Loading...

Loading...