2-6 Xerox Internal Use Only Phaser 6000/6010 and WC 6015 MFP

Theory of Operation

Exposure

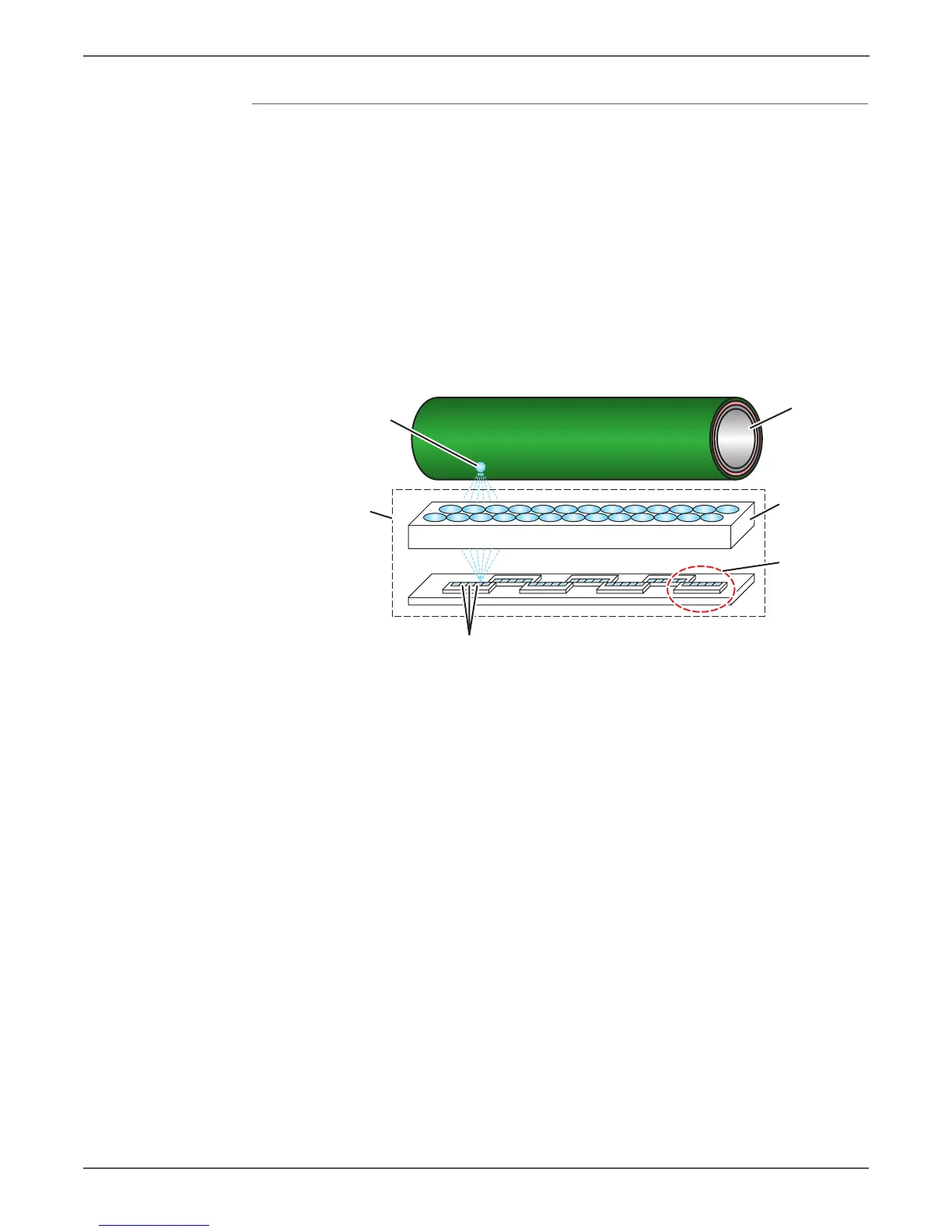

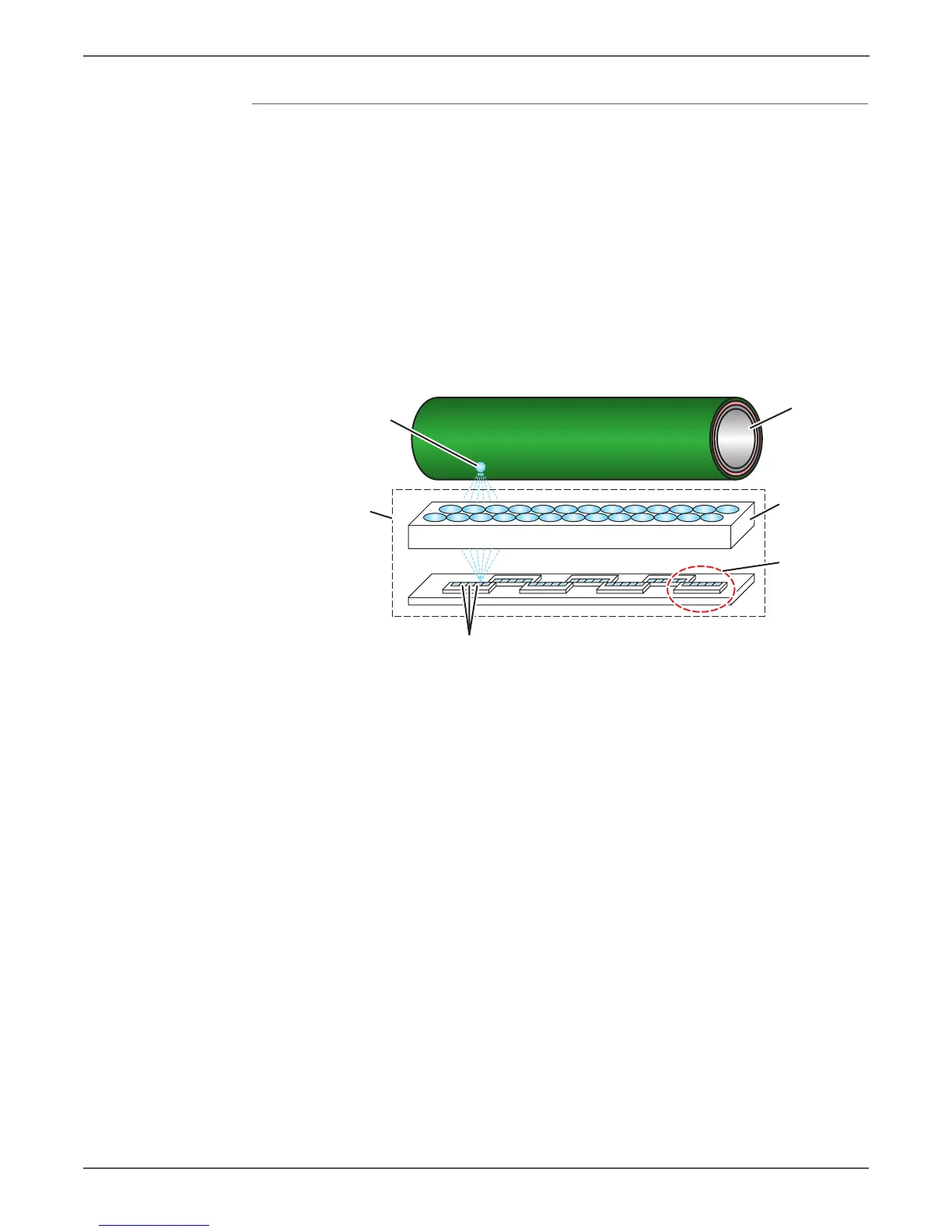

The Exposure process forms an invisible electrostatic latent image on the

negatively charged drum surface by illuminating it with the LEDs (Light Emitting

Diodes). This process is performed in parallel for Yellow, Magenta, Cyan, and Black

colors.

The printers uses a LED Print Head (LPH) for exposure. The LPH is made up of

numerous LEDs that are lined up in the fast scan direction.

The LPH has 57 SLEDs (Self-Scanning Light Emitting Diodes), and each SLED has

256 dots of luminous points. The result is 14592 luminous dots that are capable of

producing a high quality image of 1200 dpi in the fast scan direction.

The LEDs are lit in one line units based on the print data (image data) that is sent

from the printer controller.

The lenses then focus the light onto the drum surface. The LED is only lit for the

parts where the one line is made up of pixels (small dots that form characters or

images). When parts of the drum surface are exposed, they become conductive

and the negative charges flow towards the positive side to cancel out the positive

charges, reducing the potential on the drum surface. These sections with lowered

surface potential form the electrostatic latent image.

s6000-056

Drum

Exposure

Point

Illuminating point

SLED

LPH

Aggregated

Optical

System

Loading...

Loading...