5.7 H: Terminal Functions

260 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

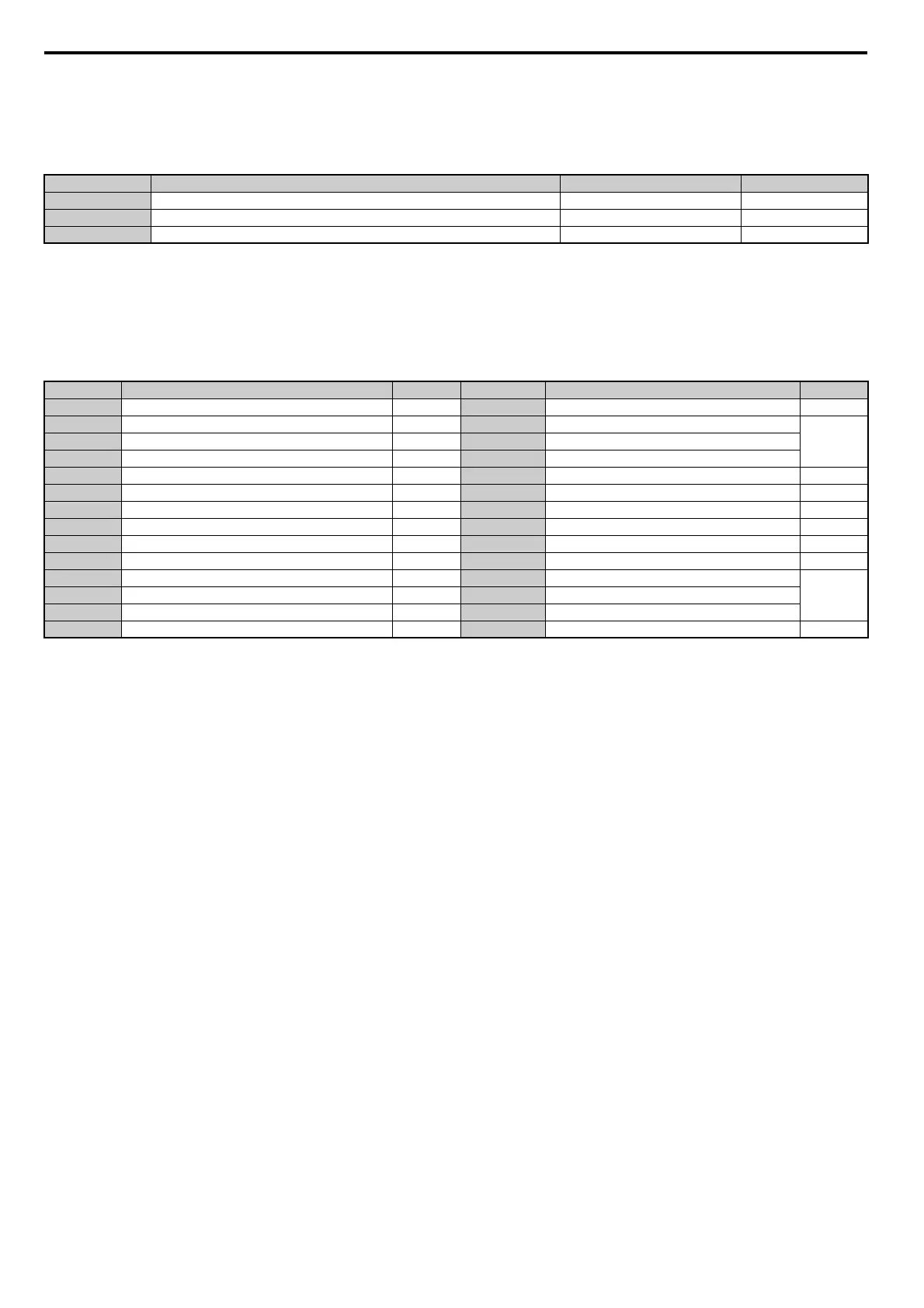

H3-16 to H3-18 Terminal A1/A2/A3 Offset

Parameters H3-16 to H3-18 set the offset level of the selected input value to terminal A1, A2 or A3 that is equal to 0 Vdc

input. These parameters rarely need adjustment.

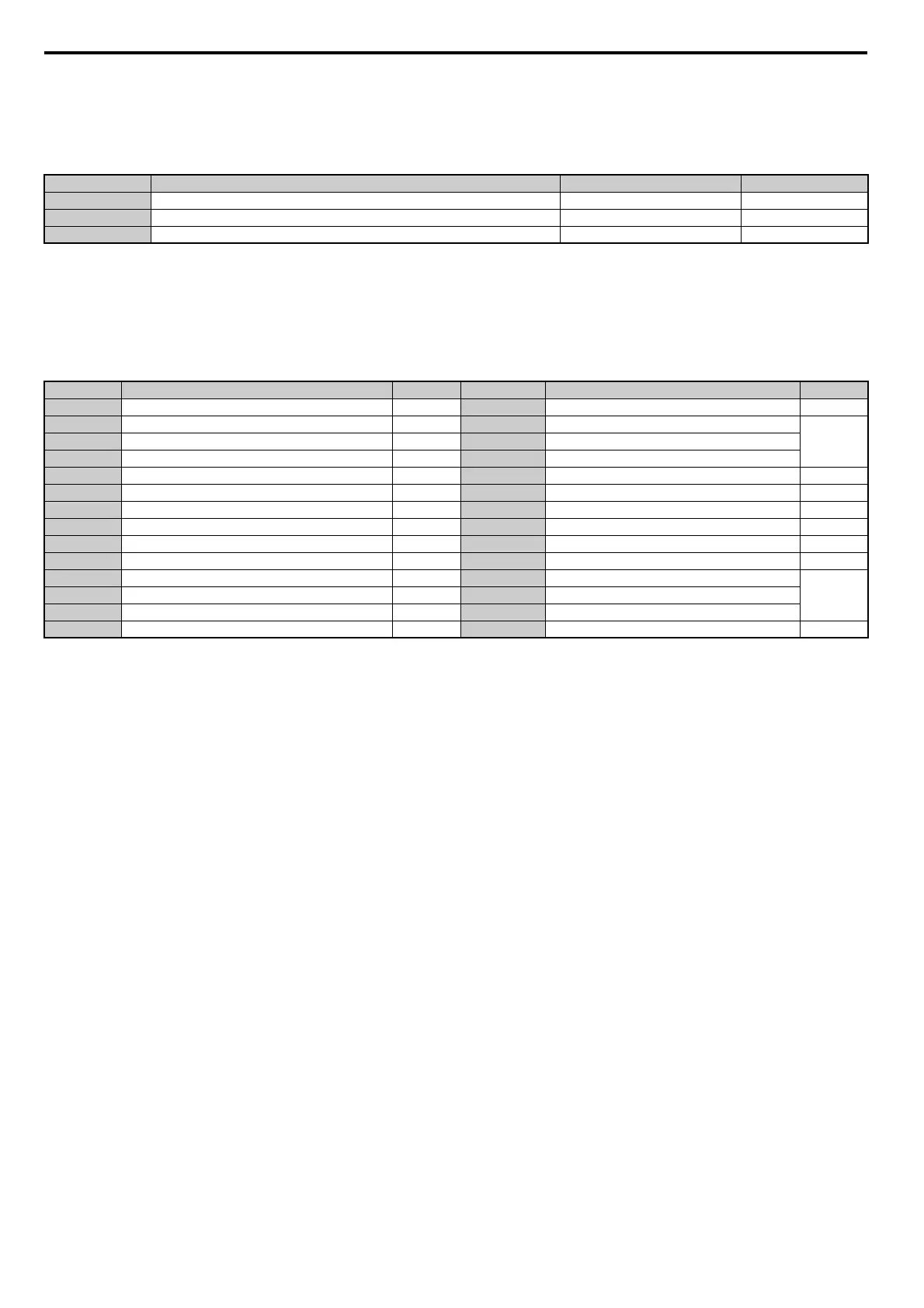

Multi-Function Analog Input Terminal Settings

See Table 5.41 for information on how H3-02, H3-10, and H3-06 determine functions for terminals A1, A2, and A3.

Note: The scaling of all input functions depends on the gain and bias settings for the analog inputs. Set these to appropriate values

when selecting and adjusting analog input functions.

Table 5.41 Multi-Function Analog Input Terminal Settings

Setting 0: Frequency bias

The input value of an analog input set to this function will be added to the analog frequency reference value. When the

frequency reference is supplied by a different source other than the analog inputs, this function will have no effect. Use

this setting also when only one of the analog inputs is used to supply the frequency reference.

By default, analog inputs A1 and A2 a

re set for this function. Using A1 and A2 at the same time increases the frequency

reference by the total of all inputs.

Example: If the analog frequency

reference from analog input terminal A1 is 50% and a bias of 20% is applied by analog

input terminal A2, the resulting frequency reference will be 70% of the maximum output frequency.

Setting 1: Frequency gain

The input value of an analog input set to this function will be multiplied with the analog frequency reference value.

Example: If the analog frequency reference from

analog input terminal A1 is 80% and a gain of 50% is applied from

analog input terminal A2, the resulting frequency reference will be 40% of the maximum output frequency.

Setting 2: Auxiliary reference 1

Sets the auxiliary frequency reference 1 when multi-step speed operation is selected. Refer to Multi-Step Speed

Selection on page 198 for details.

Setting 3: Auxiliary reference 2

Sets the auxiliary frequency reference 2 when multi-step speed operation is selected. Refer to Multi-Step Speed

Selection on page 198 for details.

Setting 4: Output voltage bias

Voltage bias boosts the output voltage of the V/f curve as a percentage of the maximum output voltage (E1-05). Available

only when using V/f Control.

No. Name Setting Range Default

H3-16 Terminal A1 Offset -500 to 500 0

H3-17 Terminal A2 Offset -500 to 500 0

H3-18 Terminal A3 Offset -500 to 500 0

Setting Function Page Setting Function Page

0

<1> This function is available in models CIMR-A4A0930 and 4A1200.

Frequency bias 260 F Through mode 262

1 Frequency gain 260 10 Forward torque limit

262

2 Auxiliary frequency reference 1 260 11 Reverse Torque Limit

3 Auxiliary frequency reference 2 260 12 Regenerative torque limit

4 Output voltage bias 260 13 Torque limit using torque reference/speed control 262

5 Accel/decel time gain 261 14 Torque compensation 262

6 DC Injection Braking current 261 15 General torque limit 262

7 Torque detection level 261 16 Differential PID feedback 262

8 Stall Prevention level during run 261 17 <1> Motor Thermistor (NTC) 262

9 Output frequency lower limit level 261 1F Through mode 262

B PID feedback 261 30 DriveWorksEZ analog input 1

262

C PID setpoint 261 31 DriveWorksEZ analog input 2

D Frequency bias 262 32 DriveWorksEZ analog input 3

E Motor temperature (PTC input) 262 – – –

Loading...

Loading...