Measuring Control

Systems

The Agilent 35670A is useful for characterizing the performance and stability

of a control system. Performance parameters, such as rise time, overshoot, and

settling time, are generally specified in the time domain. Stability criteria,

gain/phase margins, are generally specified in the frequency domain. The

Agilent 35670A measures both in the time and frequency domains.

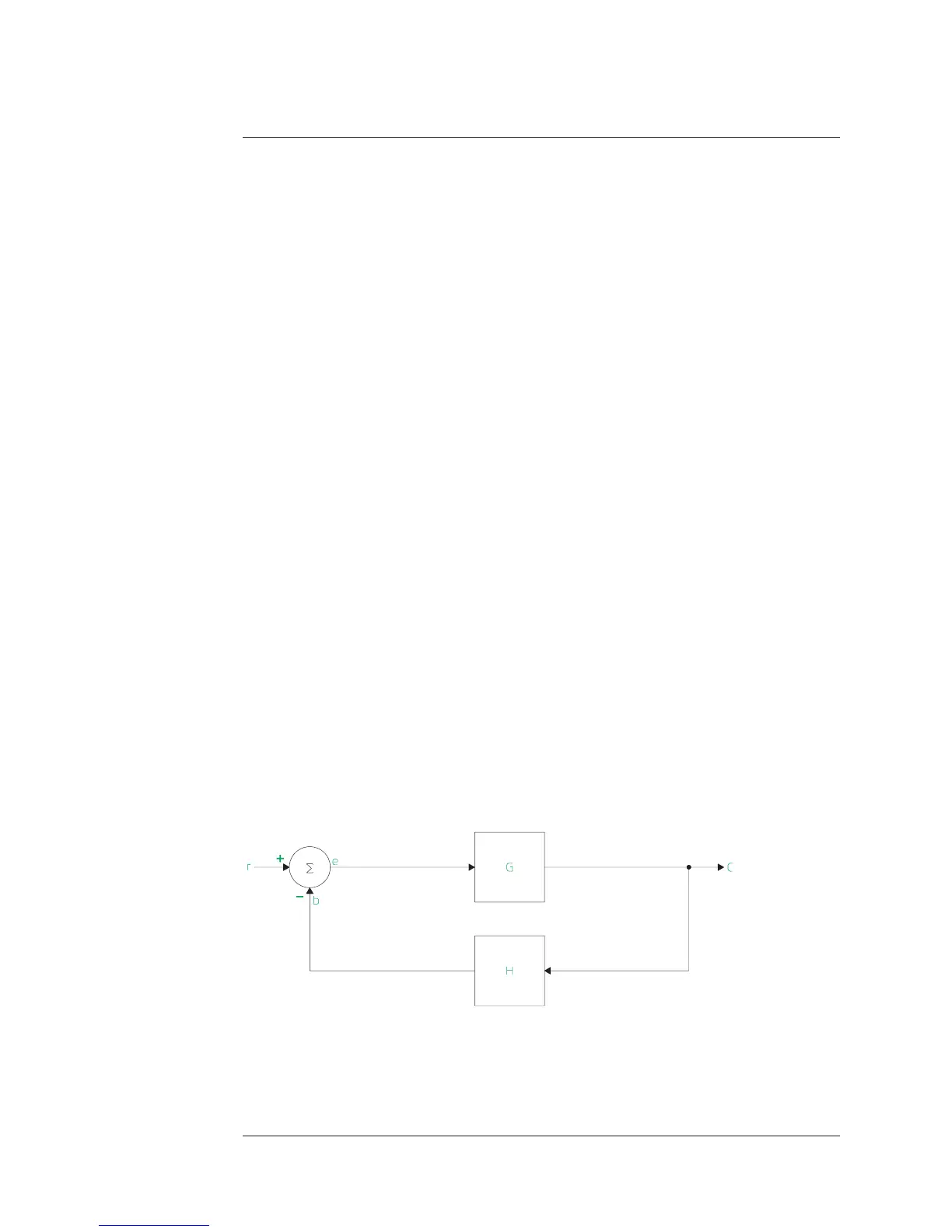

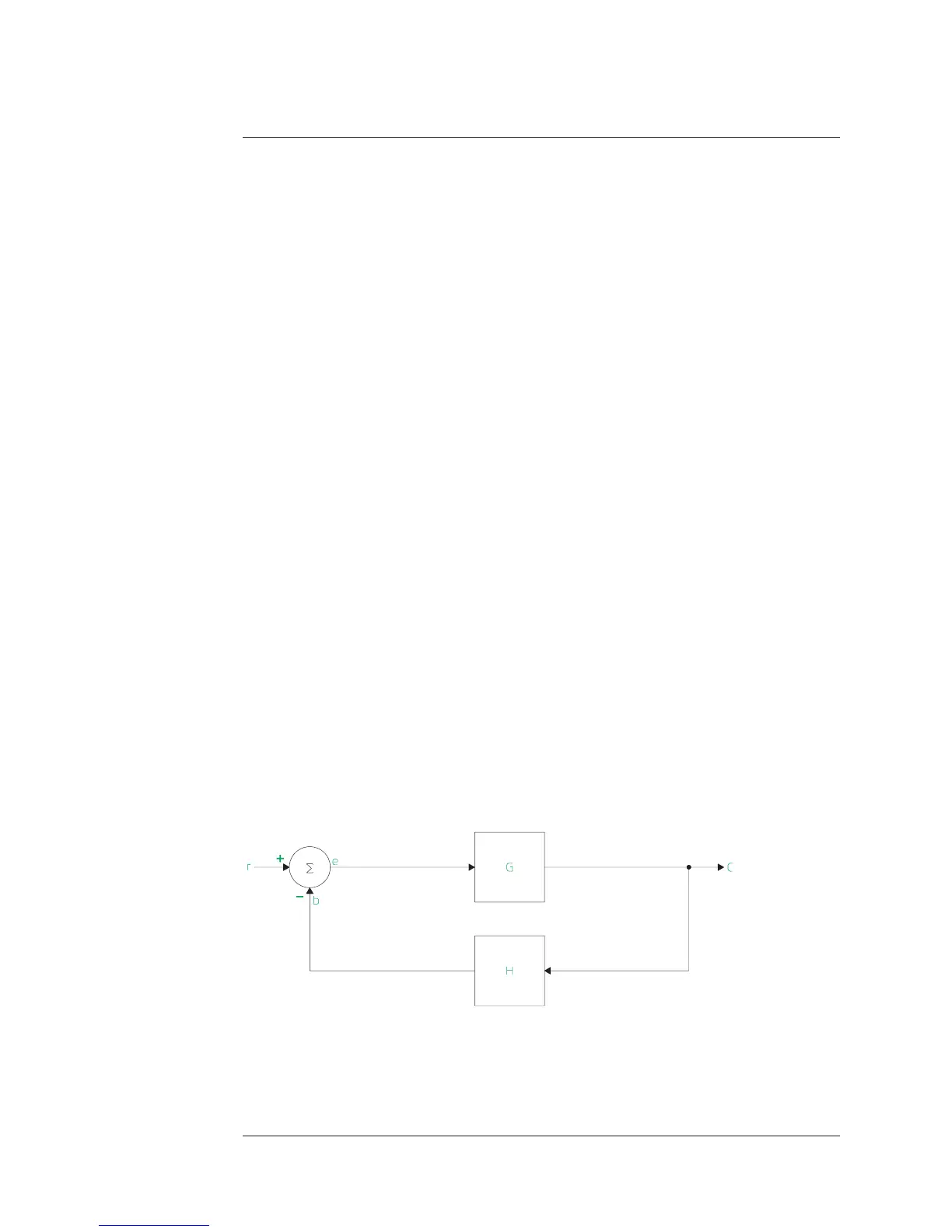

General Model of a Control System

The standard model of a single loop control system consists of

• an input signal called the reference signal (r)

• a device or a process to control (called the “plant”)

• a sensor to measure the response of the plant (c)

• a feedback element, H, and summation block to give an indication (b) of the output

(c) so that they may be combined with the original control signal to form an error

signal (e)

• an error signal, that is sent to the plant such that c is driven to minimize the error

between c and r

Figure 5-1 is a generic block diagram of a control or “servo” system. The

plant’s transfer function is G. The feedback transfer function is H. The goal is

to optimize closed loop performance. This is done by modifying the open loop

elements. Ideally, the control loop output (c) tracks the input (r) perfectly in

the time domain; the gain (output/input) is 1 and there is no phase lag between

input and output.

Figure 5-1

Block Diagram of a Control System

Agilent 35670A

Measuring Control Systems Operator's Guide

5-2

Loading...

Loading...