Commissioning

Data set for parameter values and motor data

For motor data of different motors or adjustment to different operating

points.

setup

Select "Setup" menu. Press ENT.

The data set selection is displayed.

Select the data set where the entered and measured motor data and

parameter values are to be saved.

− Select data set 0 if all data sets are to contain the same parameter

values.

− Select one of the data sets 1 ... 4 for commissioning of several mo-

tors or for different operating points.

Example: For auto set-up (auto-tuning)

and motor data, select data

set 1.

rameter val-

ue

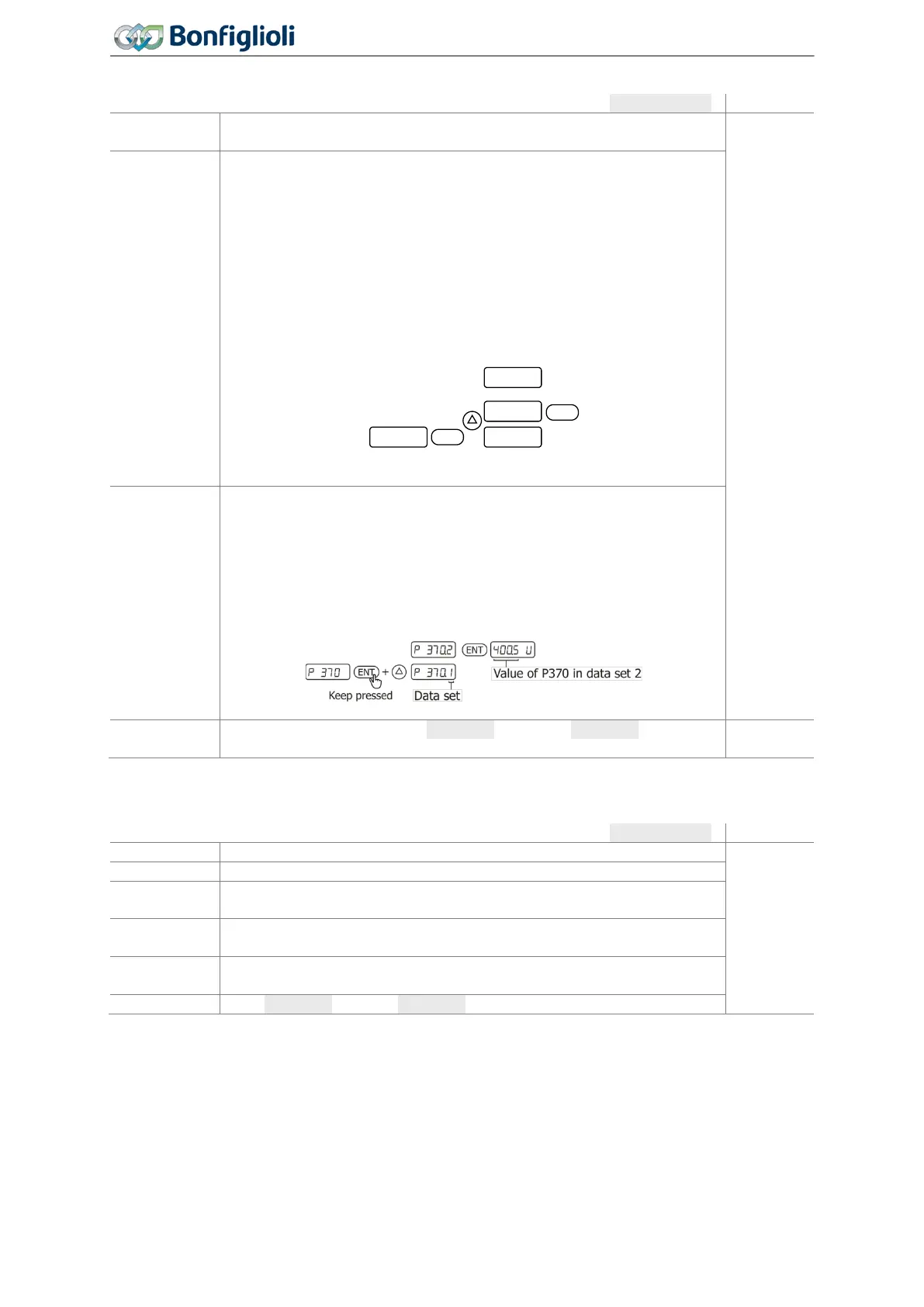

Set parameter values in a certain data set:

In menu "Para", select the parameter to be set.

Keeping ENT pressed, press arrow key. The last digit shows the data

set.

Release ENT and press again. Now, you can set the parameter value

using the arrow buttons.

Example: Set nominal motor voltage P370 in data set 2.

Select digital inputs for P70 (73 - IN3D) and P71 (74 - IN4D).

Select a data set value via these digital inputs.

PID controller (technology controller)

Process control (e.g. pressure, flow rate, temperature).

Set P475 or P492 to "30 - Technology controller".

For P476 or P494, select the source specifying the reference value.

For P478, select the input where the actual value is applied. The actual

value can also be received via a communication interface.

P444 proportional component (amplification), P445 integral component

(integral time), P446 differential component (derivative time).

P68 (71 - IN1D) or P69 (72 - IN2D).

Data set

ENT

ENT

.

.

.

94

Operating Instructions

Agile

06/2013 Typical functions

Loading...

Loading...