Chapter 3 Image Quality Troubleshooting

3.2 Image Quality Troubleshooting

3-18

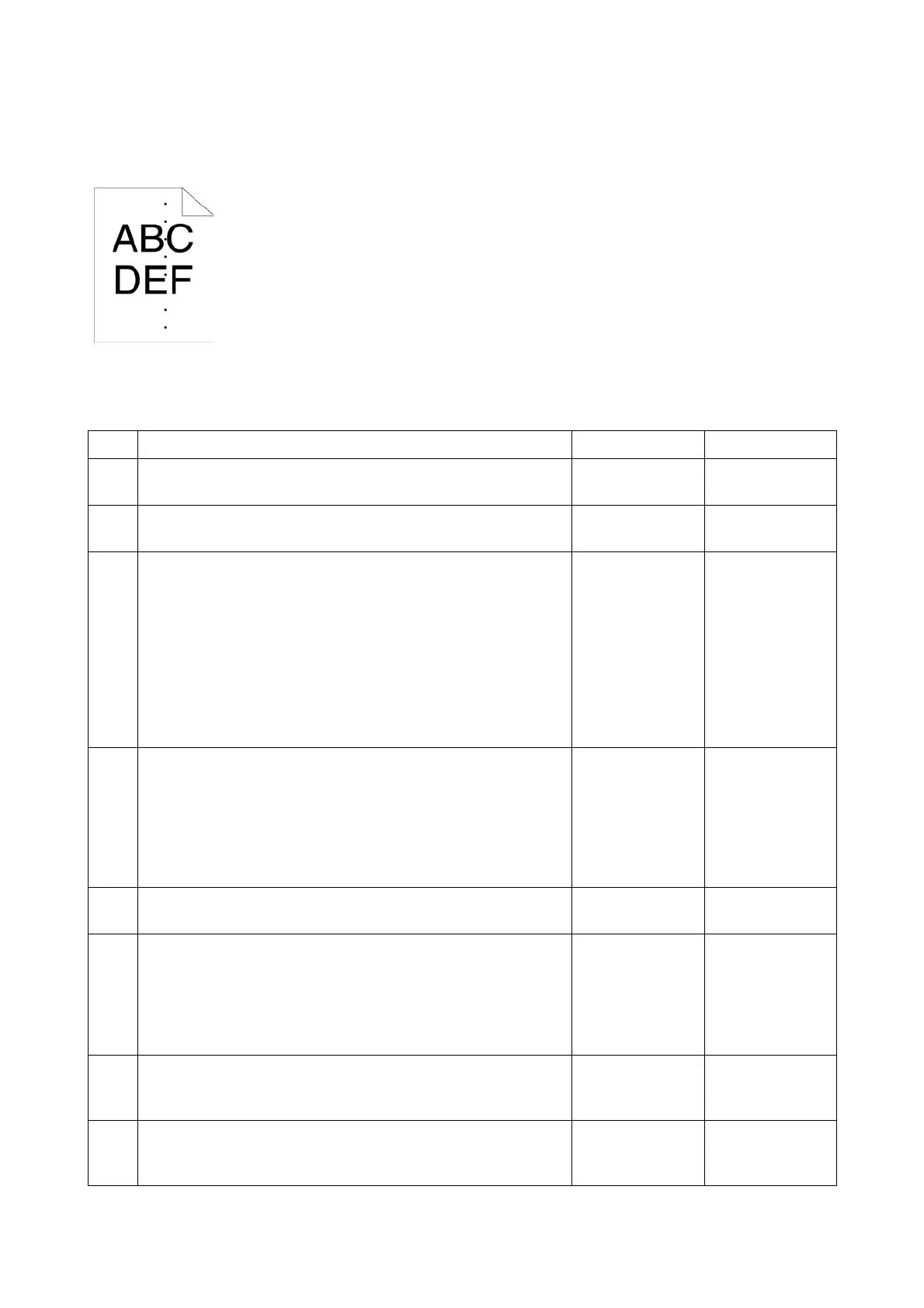

IQ-7 Pitched black dots

Possible causative parts

- IIT ASSY (PL21.1.14)

- DADF ASSY (PL21.1.1)

- Transfer Unit [ROLL ASSY-TRANS CRU] (PL6.1.1)

- Drum Cartridge [XERO ASSY] (PL8.1.1)

- FUSING UNIT (PL7.1.1)

- HVPS (PL18.2.5)

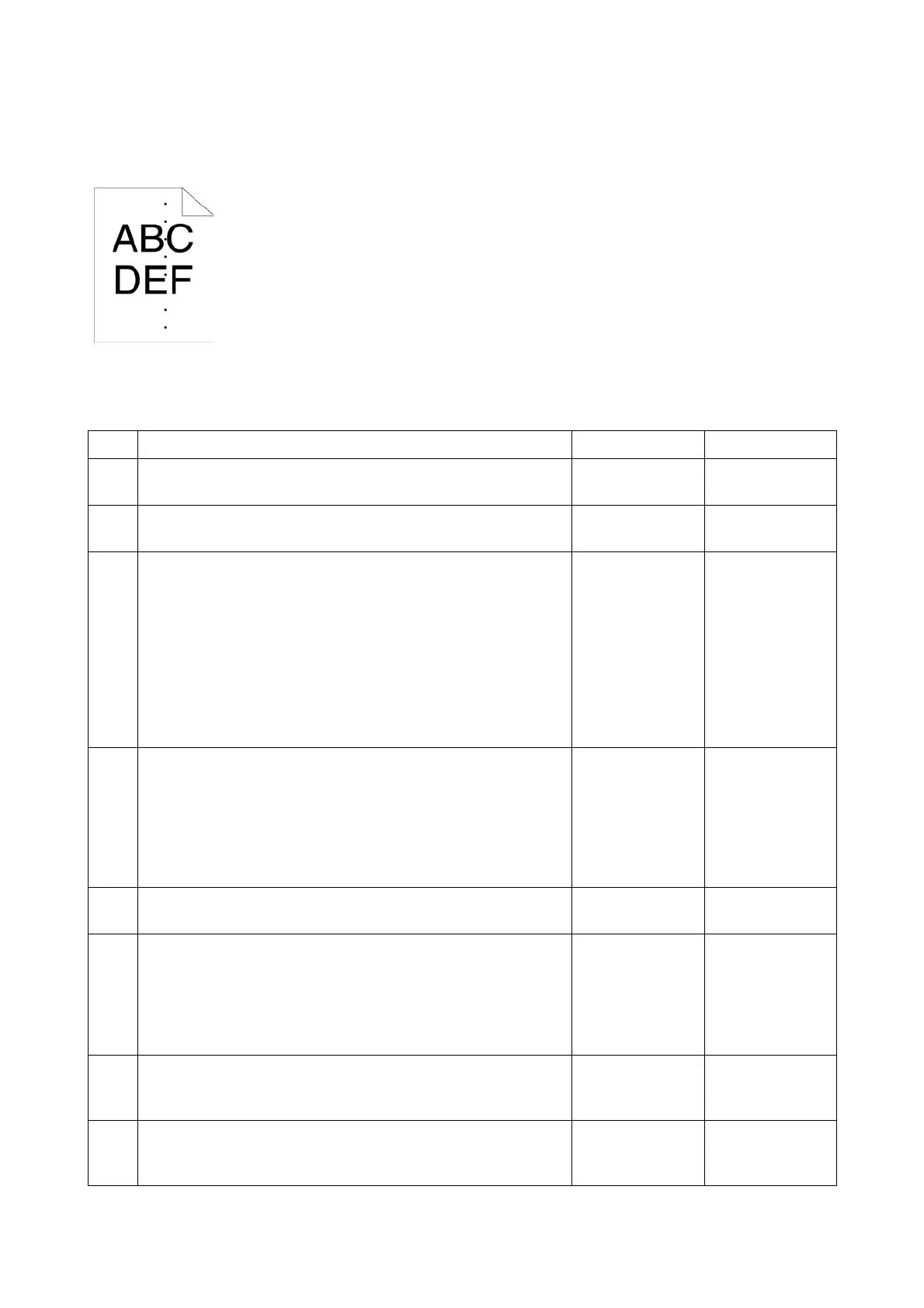

Step Check and Action Yes No

1

Checking the error mode.

Does the error occur only during copying?

Go to step 2. Go to step 4.

2

Checking the original.

Is the original color clean?

Go to step 3.

End, checking

the original.

3

Checking the platen glass and DADF Feed Roller.

Are there any damages or foreign substance?

Remove the for-

eign substances

or Clean up the

IIT/DADF. If

platen glass has

been damaged,

Replace the IIT

ASSY (REP

21.1). Then go to

step 4.

Go to step 4.

4

Checking the defective parts.

Print the [Pitch Chart] in [Chart] in [Maintenance] of [Admin

Menu].

When the partial lacks of periodicity are observed, check the

defective parts by comparing the printed partial lacks with the

Pitch Chart.

Are there any partial lacks matching the chart?

Replace the cor-

responding parts.

Go to step 5.

Go to step 5.

5

Checking after cleaning Inside the Printer.

Is the image printed correctly?

End of work. Go to step 6.

6

Checking the Transfer Unit for connection.

Remove the Transfer Unit.

Are the Plate Spring BTR on HVPS dirty or deformed?

Clean up the

Plate Spring BTR

or Replace the

HVPS (REP

18.3), then go to

step 7.

Go to step 7.

7

Checking after resetting the Transfer Unit.

Reseat the Transfer Unit.

Is the image printed correctly?

End of work. Go to step 8.

8

Checking after replacing the Transfer Unit.

Replace the Transfer Unit.

Is the image printed correctly?

End of work. Go to step 9.

Loading...

Loading...