Chapter 3 Image Quality Troubleshooting

3.2 Image Quality Troubleshooting

3-36

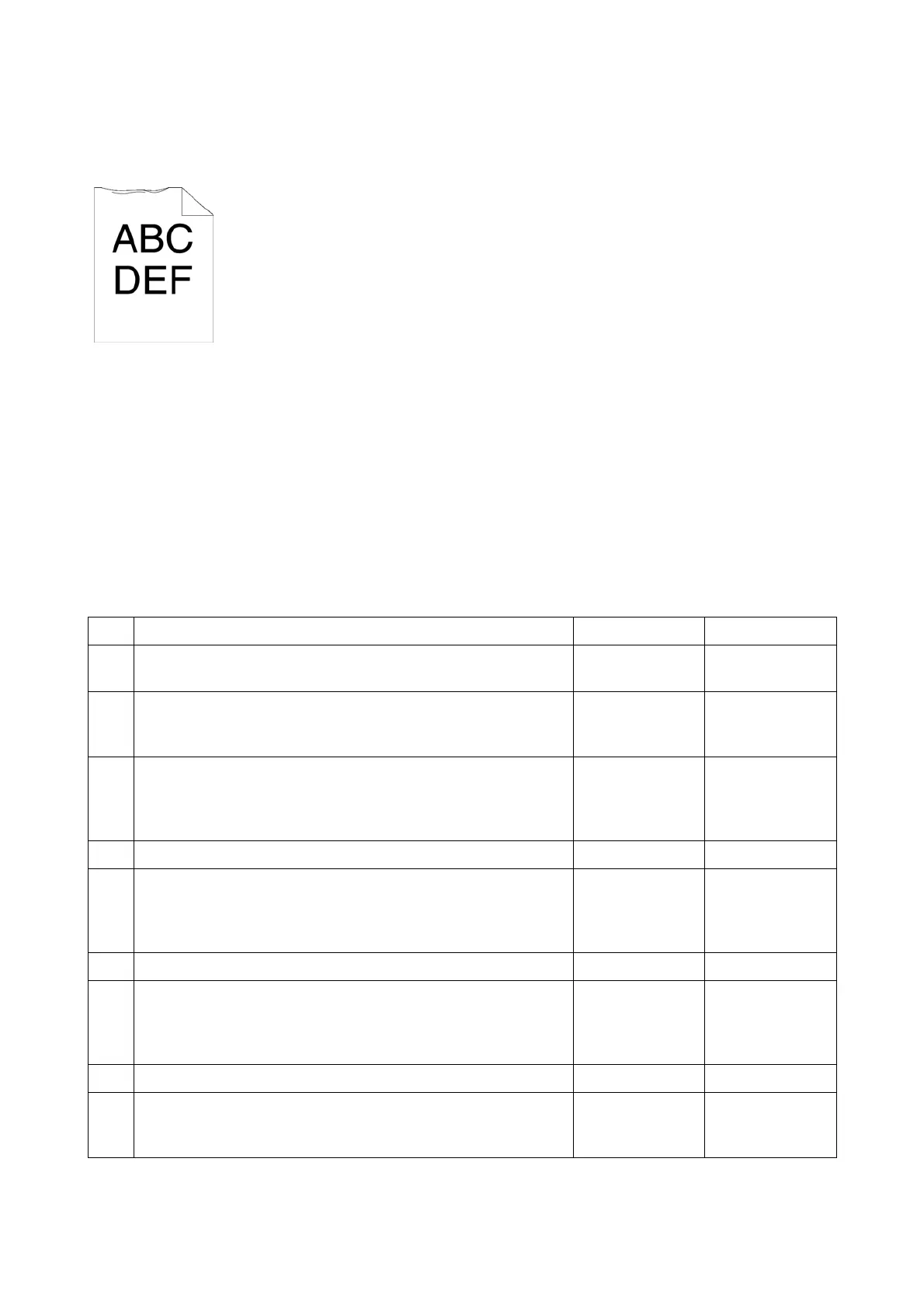

IQ-17 Damage on the leading edge of paper

Possible causative parts

- ROLL ASSY RUBBER (PL15.2.6)

- ROLL ASSY REGI PINCH (PL15.2.8)

- ROLL REGI PINCH (PL15.2.37)

- MSI Feed Roll / Nudger Roll [HOLDER ASSY PICK UP](PL13.1.15)

- KIT RETARD ROLL MSI ASSY(PL13.2.98)

- Tray 1 Feed Roll / Nudger Roll [FEEDER ASSY](PL15.3.2)

- Tray 1 Retard Roll [HOLDER ASSY RETARD CST] (PL9.1.3)

- Transfer Unit [ROLL ASSY-TRANS CRU] (PL6.1.1)

- Drum Cartridge [XERO ASSY] (PL8.1.1)

- Tray 2 Feed Roll / Nudger Roll [ROLL ASSY FEED](PL10.2.13)(Option)

- Tray 2 Retard Roll [HOLDER ASSY RETARD CST](PL10.3.3)(Option)

- ROLL ASSY EXIT (PL17.1.5)

- KIT PINCH ASSY L(PL17.1.6)

- KIT PINCH ASSY R(PL17.1.7)

- Heat Roll [FUSING UNIT] (PL7.1.1)

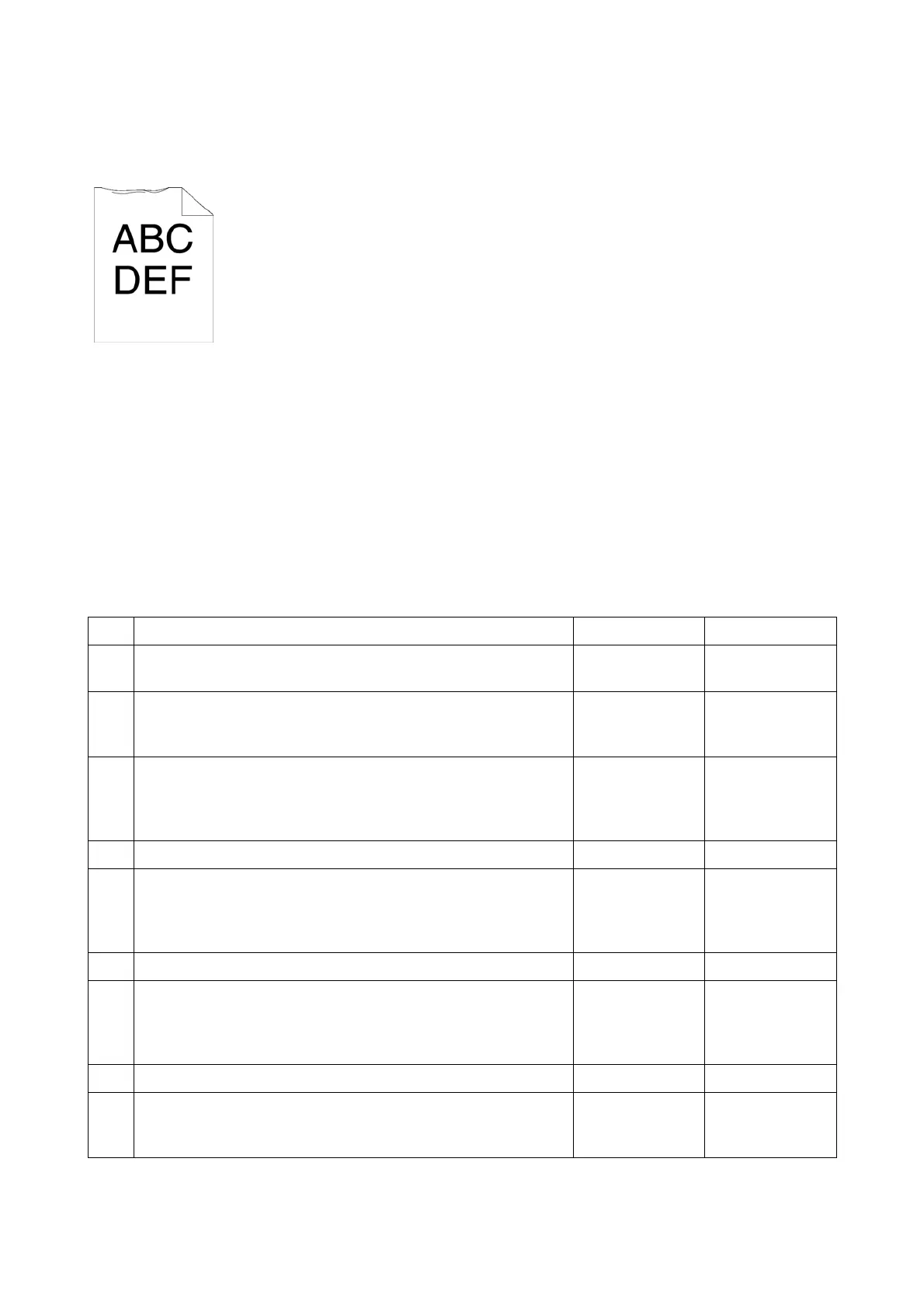

Step Check and Action Yes No

1

Checking the paper feeding tray.

Is the skewed paper fed from the MSI?

Go to step 2. Go to step 3.

2

Checking the side guides of MSI.

Reset the side guides.

Is the image printed correctly?

End of work. Go to step 3.

3

Checking the paper path.

Are there any foreign substance on the paper path?

Remove the for-

eign sub-

stances, then go

to step 4.

Go to step 5.

4 Is the image printed correctly? End of work. Go to step 5.

5

Check the paper feed rolls

Are the paper feed rolls (the rolls that are listed among the

parts considered to be the cause) installed properly?

Go to Step 7.

Reinstall the cor-

responding

paper feed rolls,

then go to step 6.

6 Is the image printed correctly? End of work. Go to step 7.

7

Check the paper feed rolls

Are the paper feed rolls (the rolls that are listed among the

parts considered to be the cause in sequence) deformed or

worn out?

Replace the cor-

responding

paper feed rolls,

then go to step 8.

Go to Step 9.

8 Is the image printed correctly? End of work. Go to step 9.

9

Checking after resetting the Paper Cassette.

Reseat the Paper Cassette.

Is the image printed correctly?

End of work. Go to step 10.

Loading...

Loading...