OPERATION

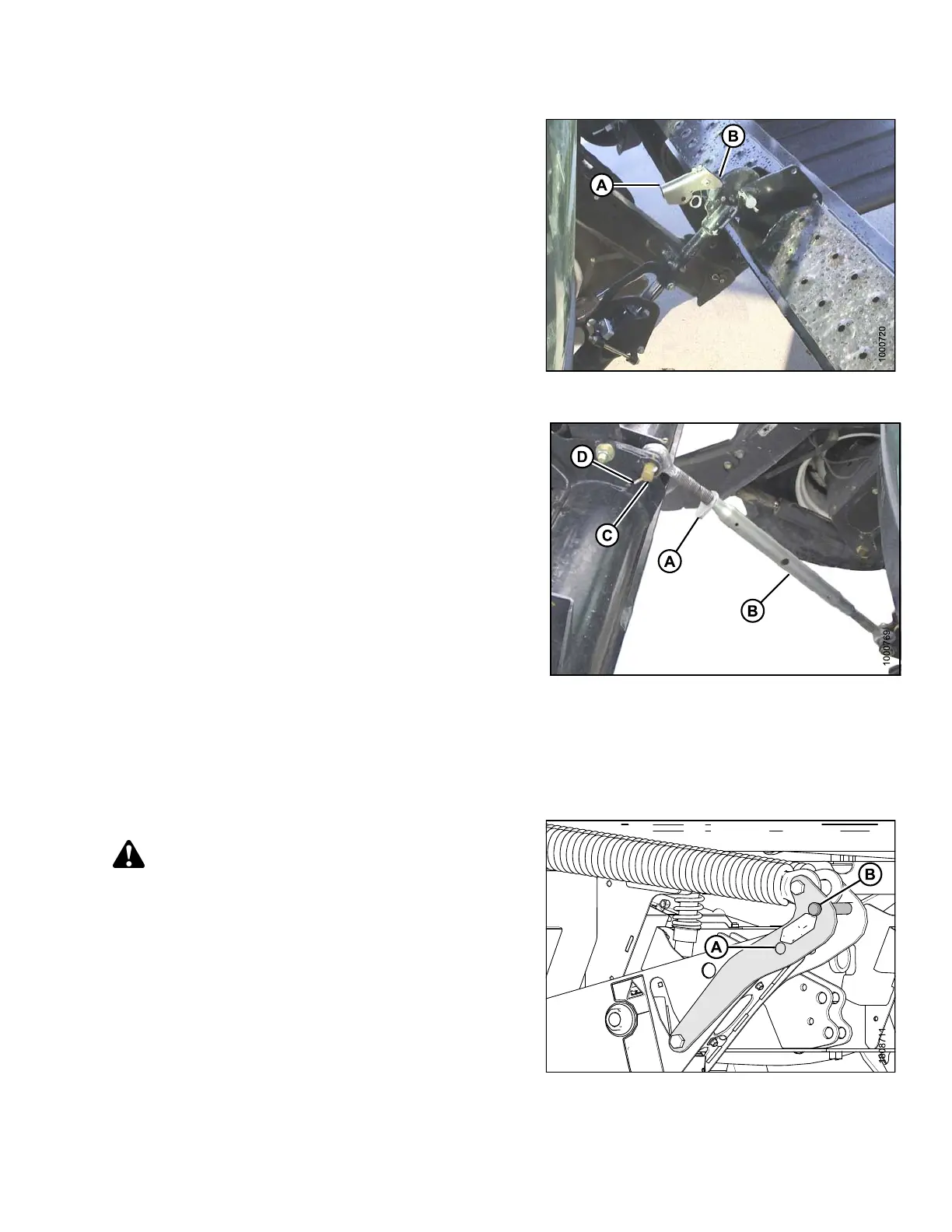

Disconnect the center-link as follows:

Hydraulic Lin k

13. If using hydraulic link, disconnect the center-link

as follows:

a. Pull up on latch (A), and position latch into notch

(B) on top of hook.

b. Release safety props on the header lift cylinders

(4.4.1 Header Safety Props, page 117).

c. Lower header down onto the transport wheels.

d. Disengage top link from the header. If necessary,

use the HEADER TILT switch to release load on

the cylinder.

Figure 4.38: Hydraulic Link

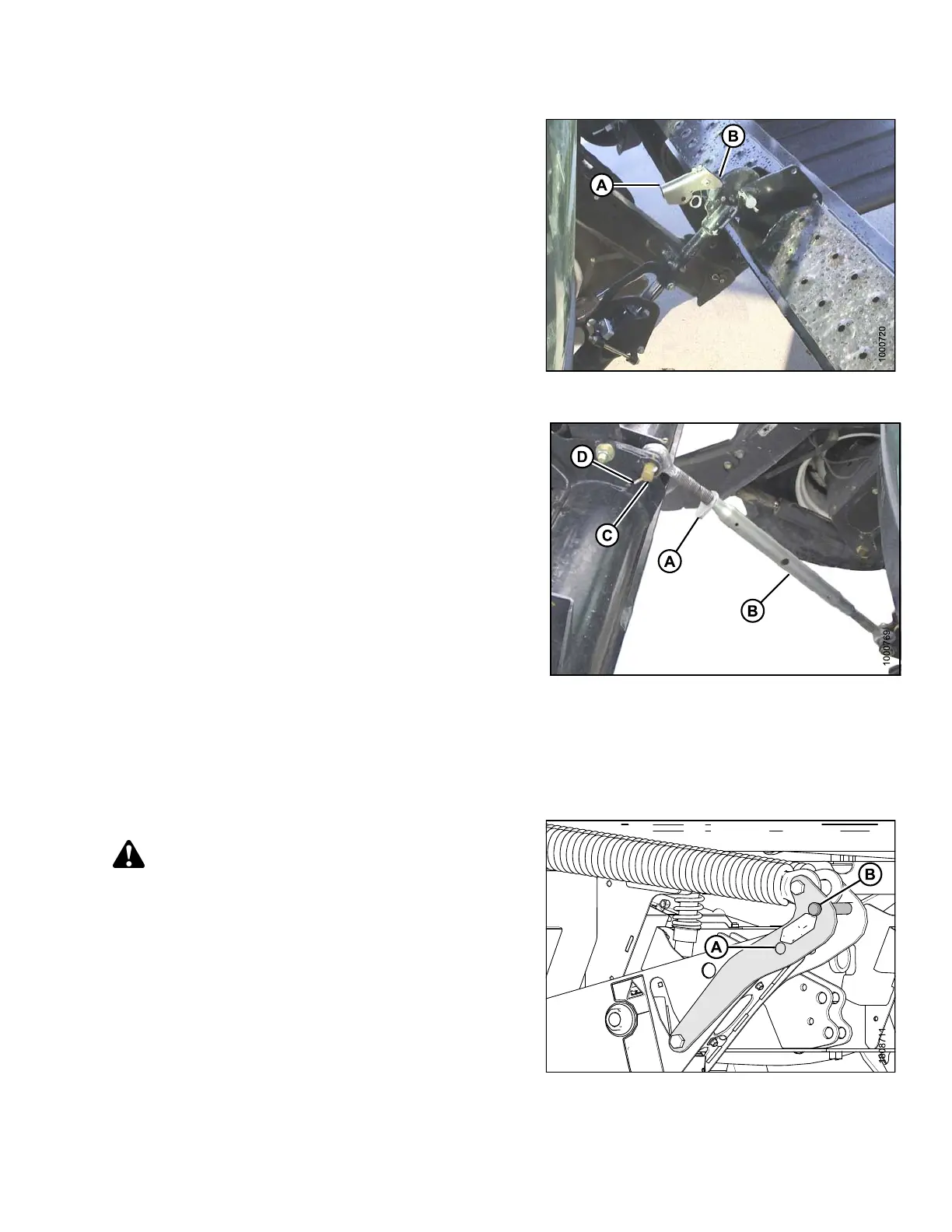

Mechanical Link

14. If using a mechanic

al lin k, disconne ct the center-lin k as

follows:

a. Loosen nut (A), an

d rotate barrel (B) to relieve load

on link.

b. Remove cotter pi

n (D) on pin (C), and remove

pin to disconnec

t from windrower. Reinstall pin

in header.

Figure 4.39: Mechanical Link

15. Back windrowe

r away from header.

16. Remove tow-ba

r sectio ns from storage locations on

header, assem

ble, and attach to header. Refer to

header opera

tor ’s manual.

Attach optional weight box to windrower as follows:

CAUTION

To prevent damage to the lift system when lowering

header lift linkages without a header or weight box

attached to windrower, ensure that float engagement

pin is installed in storage location (B) and NOT

installed at hole location (A).

Figure 4.40: Lif

tLinkage

169890 107 Revision A

Loading...

Loading...