MAINTENANCE AND SERVICING

Header and Reel Hydraulics

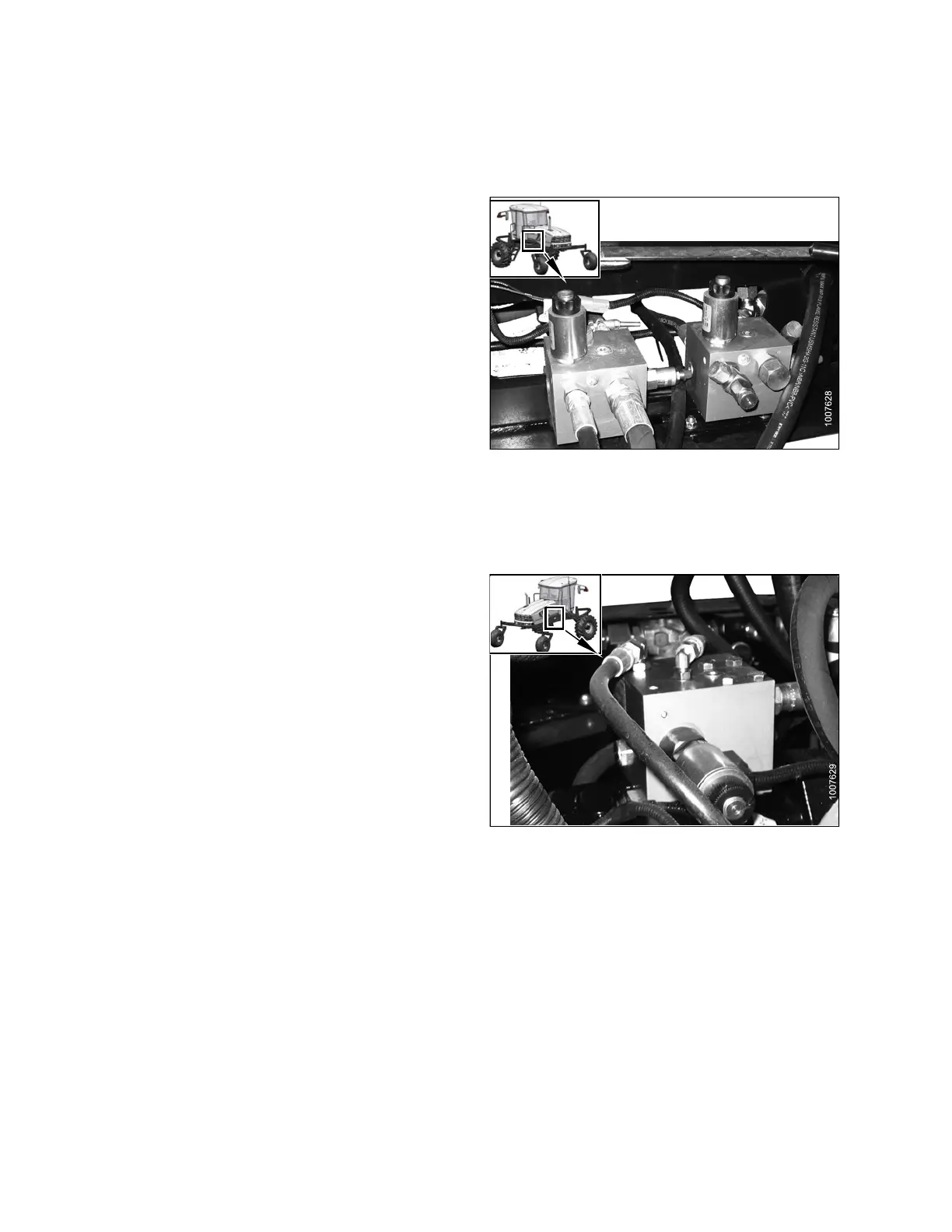

Flow Control Blocks

Two hyd ra ulic valve blocks with multiple cartridges are

used for the various windrower functions and are controlled

by the windrower control module (WCM) according to the

inputs from the Operator. The valve blocks are located

behind the left cab-forward side platform.

The valve blocks do NOT require any scheduled

maintenance other than to check for leaking fittings or

loose electrical connections. If service is required, contact

your MacDon Dealer.

Figure 5.185: Hydraulic Valve Blocks

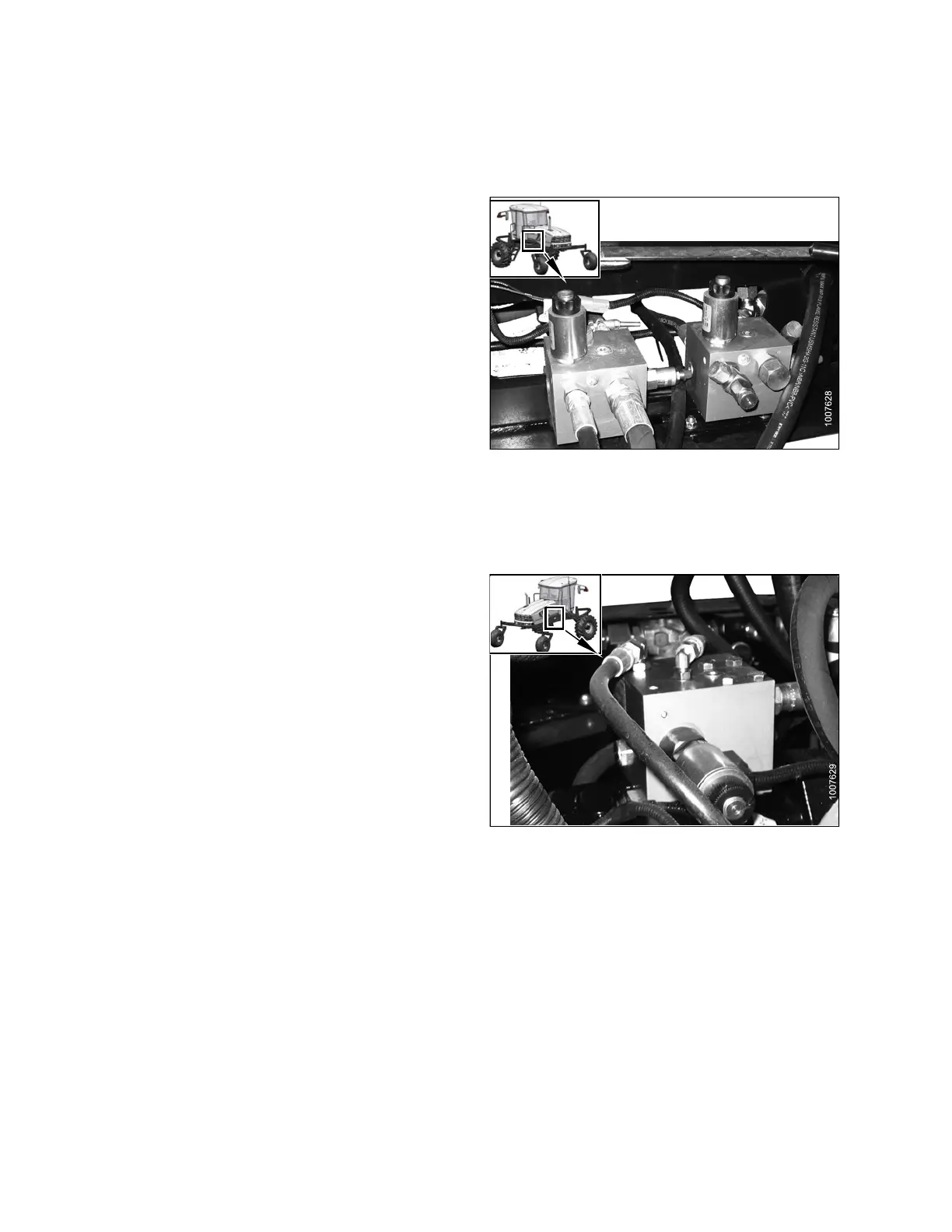

Knife Drive Valv e Bloc k

The ON/OFF valve on the valve block turns the knife ON.

It is mounted on top of the knife drive pump.

The flow to the k nife drive is mechanically set on the pump

itself. Adjusting oil flow changes knife speed.

To set the knife speed, refer to the knife speed section for

your header type:

• D-Series header: 4.6.8 Knife Speed, page 175

• A-Series header: 4.7.3 Knife Speed, page 182

Knife speed varies depending on the header size, header

type, and whether the header has a single knife or double

knife.

Knife speed is NOT monitored by cab display module

(CDM) unless the optional expansion module MD #B4666

is installed. Refer to 7.1.10 Expansion Module, page 338.

Knife speed has been factory set for lower knife speeds.

Record the knife speed for your header type here:

• HEADER TYPE: ___________________________

• RECOMMENDED KNIFE SPEED: _____________

For units used with more than one header, knife speed will

need to be changed when switching headers.

Figure 5.186: Knife Drive Valve Block

169890 294 Revision A

Loading...

Loading...